1

/

of

10

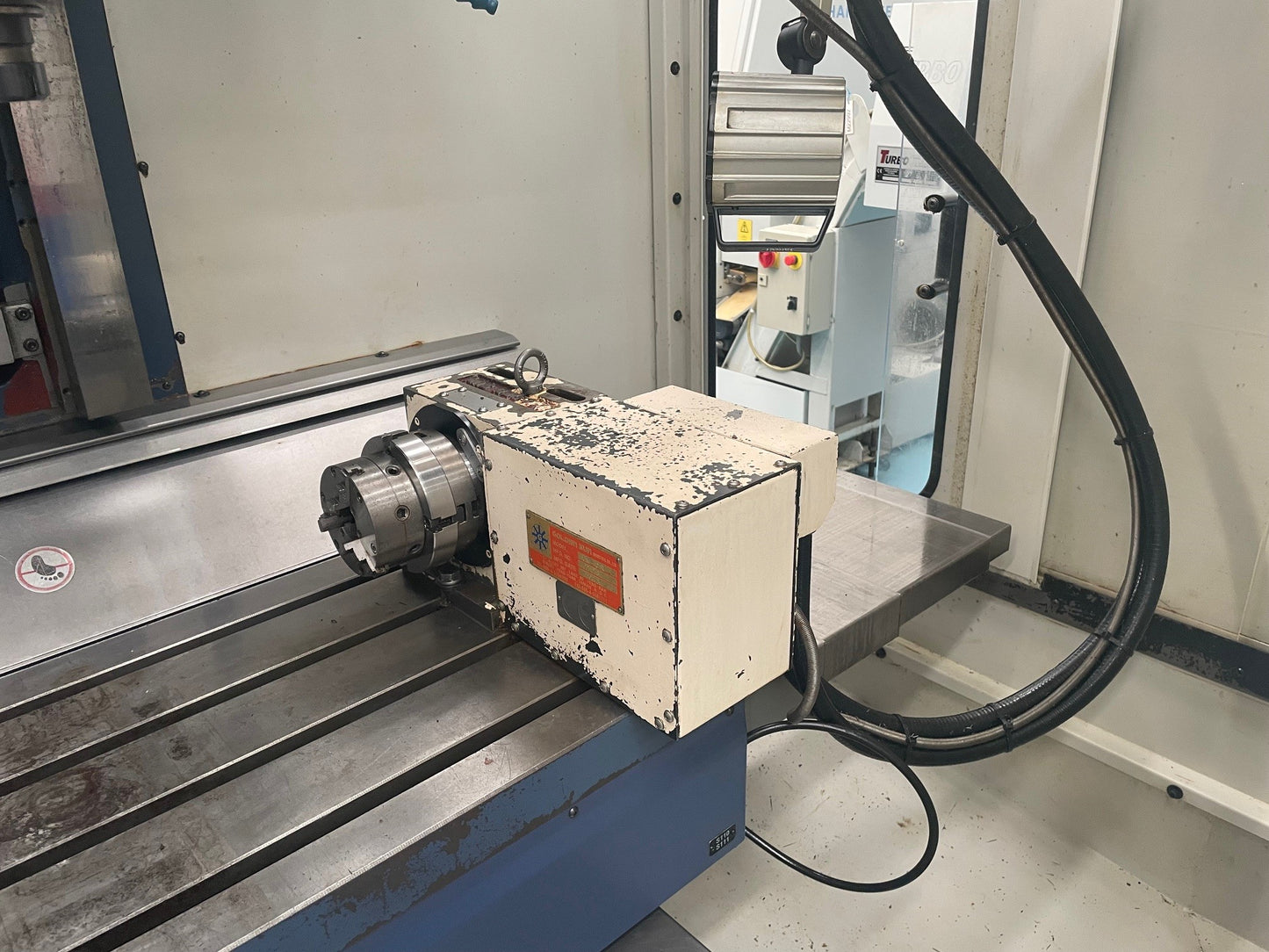

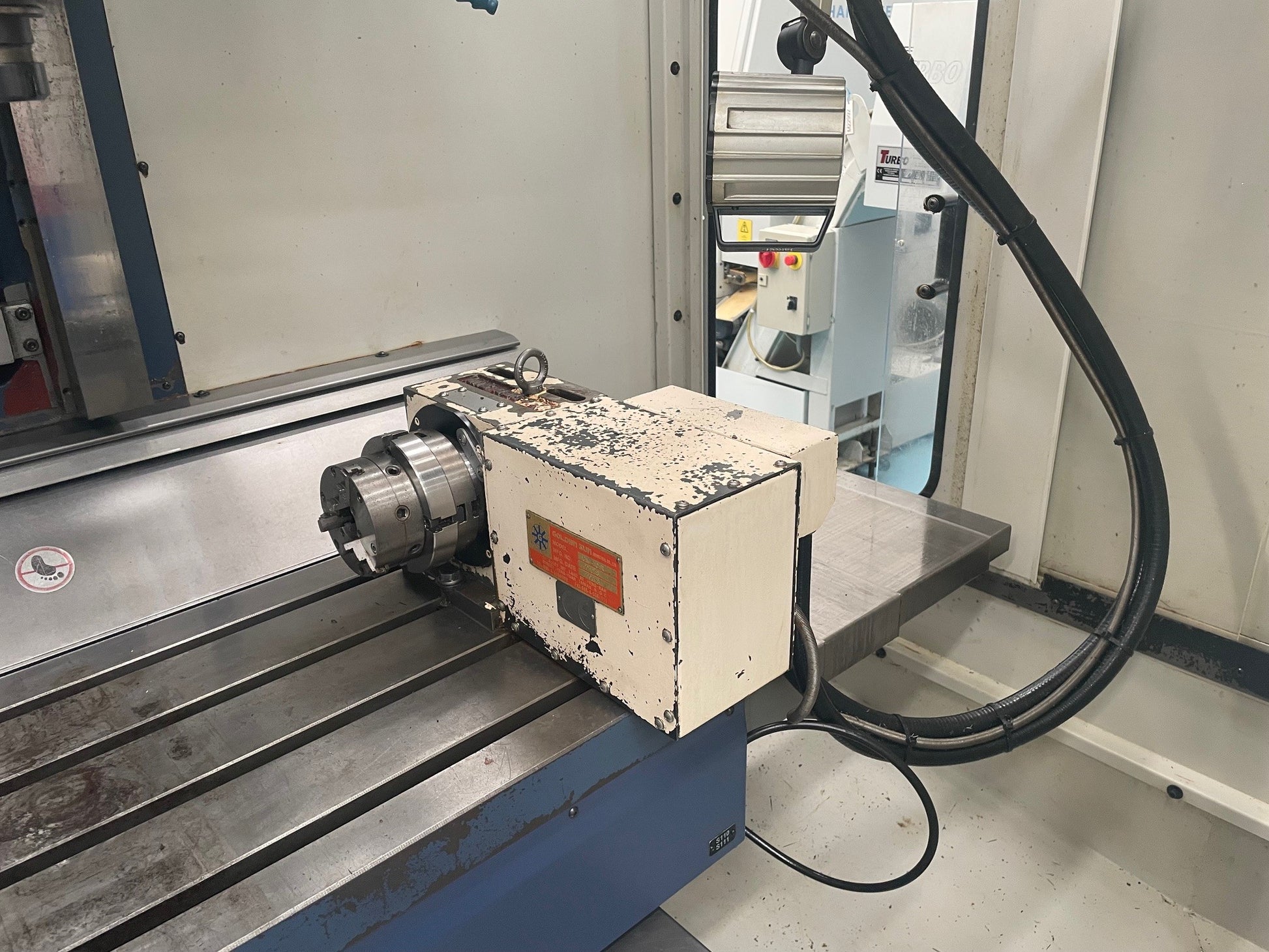

SUPERMAX YCM - V 65A

Type: YCM - V 65A

Manufacturer: SUPERMAX

Group: Machining center

Subgroup: Machining center

Control: FANUC Series O-M

Stock: 023145

SUPERMAX YCM - V 65A is a Machining center, engineered for precision, high accuracy and reliability. Table 840×420 mm (4 T‑slots 100 mm, 18 mm), table load 350 kg; travels X650 Y410 Z615 mm; BT40, spindle nose 135–750 mm. Tool changer 20 tools, tool Ø 80 mm (max 300), max tool weight 6 kg. Spindle 45–8000 rpm (stepless), spindle motor 5.5 kW, spindle power 3.7/5.5 kW; feed 10000 mm/min, rapid 16 m/min; 3x400V 50Hz, total power 17 kW; dims 2770×2110×1930 mm, weight 3600 kg. Accessories: toolholder set, coolant 130 l, 4th axis dividing attachment with tailstock, electronic handwheel, lamp, status light. Delivers tight tolerances; ideal for automotive, aerospace, medical, watchmaking and tooling.

| Number of axis total | 4 |

| Table length | 840 mm |

| Table width | 420 mm |

| Number of T-channels | 4 |

| Distance of the T-slots | 100 mm |

| T-channel width | 18 mm |

| Table load max. | 350 kg |

| Longitudinal travel (X-axis) | 650 mm |

| Transversal travel (y-axis) | 410 mm |

| Vertical travel (z axis) | 615 mm |

| Tool changer: | |

| Number of tools | 20 |

| Tool diameter | 80 mm |

| Tool diameter max. | 300 mm |

| Max. tool-weight | 6 kg |

| Spindle nose: BT | 40 |

| Distance spindle nose to table | 135 - 750 mm |

| Spindle speeds: | |

| stepless | |

| from | 45 t/min |

| up to | 8000 t/min |

| Feed range | 10000 mm/min |

| Rapid traverse: | 16 m/min |

| Rapid traverse: transversal | 16 m/min |

| Rapid traverse: vertical | 16 m/min |

| Voltage 50 Hz 3x | 400 Volt |

| Spindle motor | 5.5 kW |

| Spindle power | 3.7 / 5.5 kW |

| Total power required | 17 kW |

| Machine's weight about | 3600 kg |

| Overall dimensions machine: | |

| Length | 2770 mm |

| Width | 2110 mm |

| Height | 1930 mm |

| Various accessories: | |

| Set of toolholders | |

| Coolant system | 130 l |

| Dividing attachment 4th axis | |

| with teilstock | |

| Handwheel electroinic | |

| Lamp | |

| Status light |

Need Assistance? Just WhatsApp Us!

Need Assistance? Just WhatsApp Us!