1

/

of

15

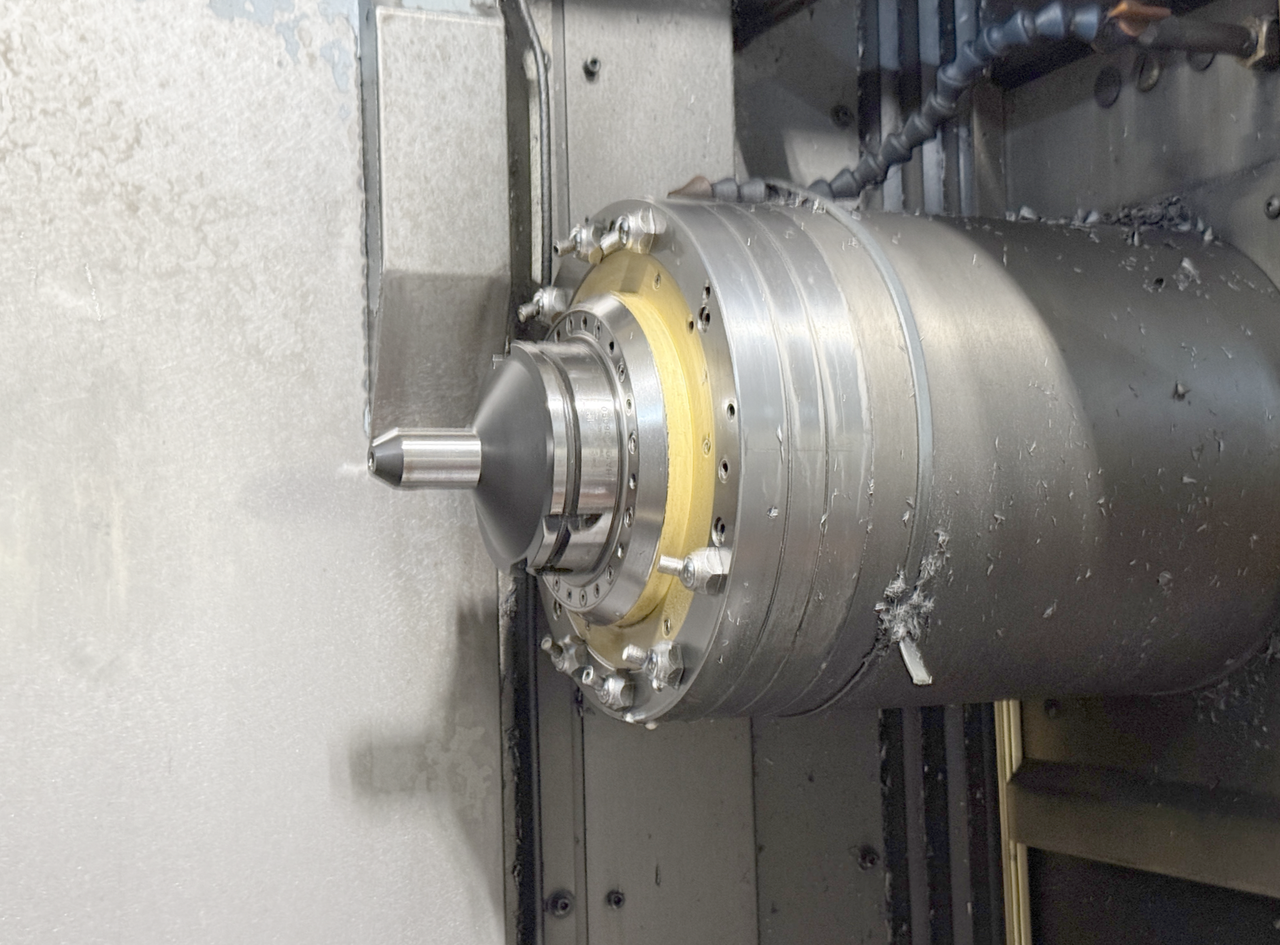

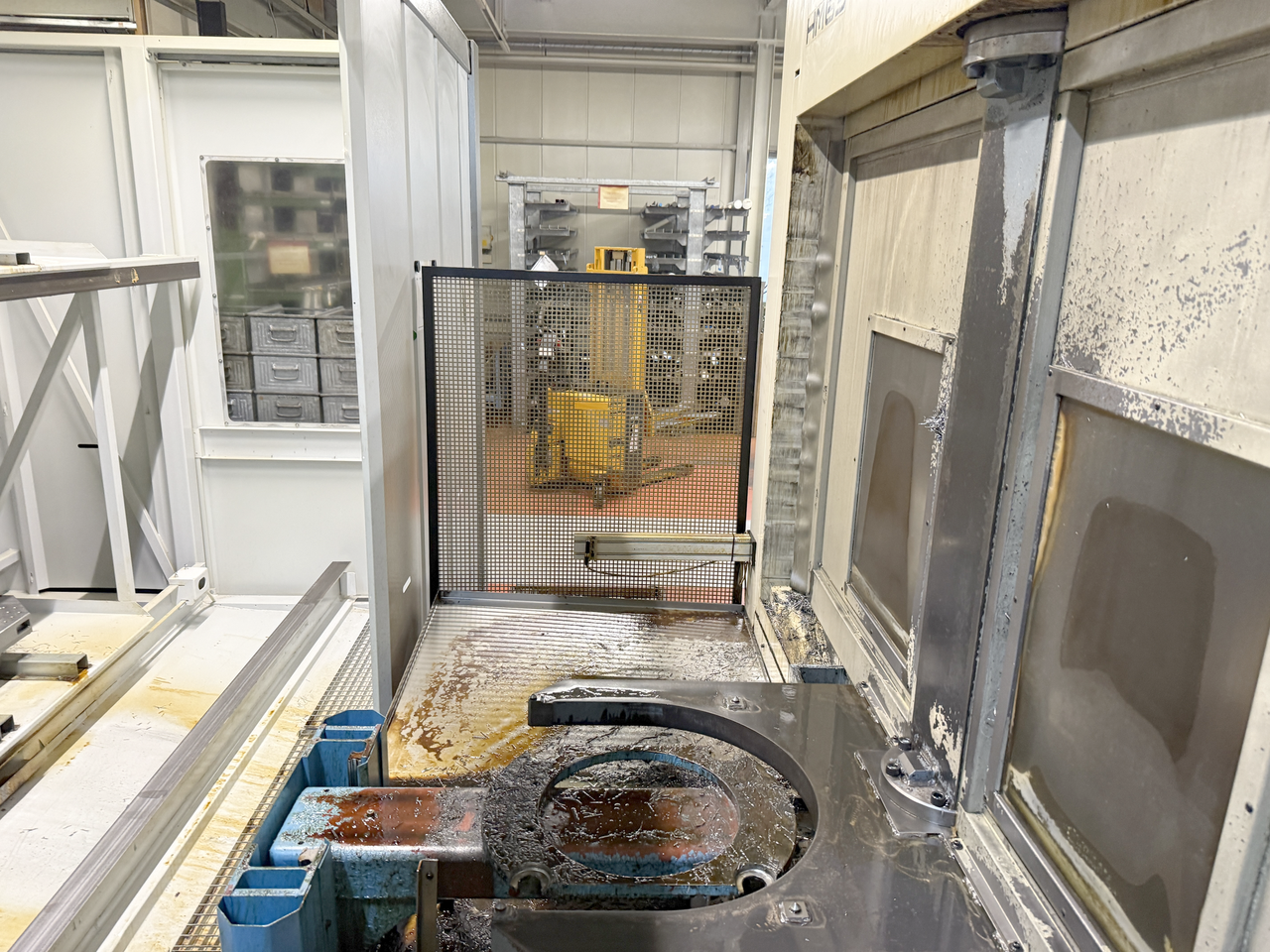

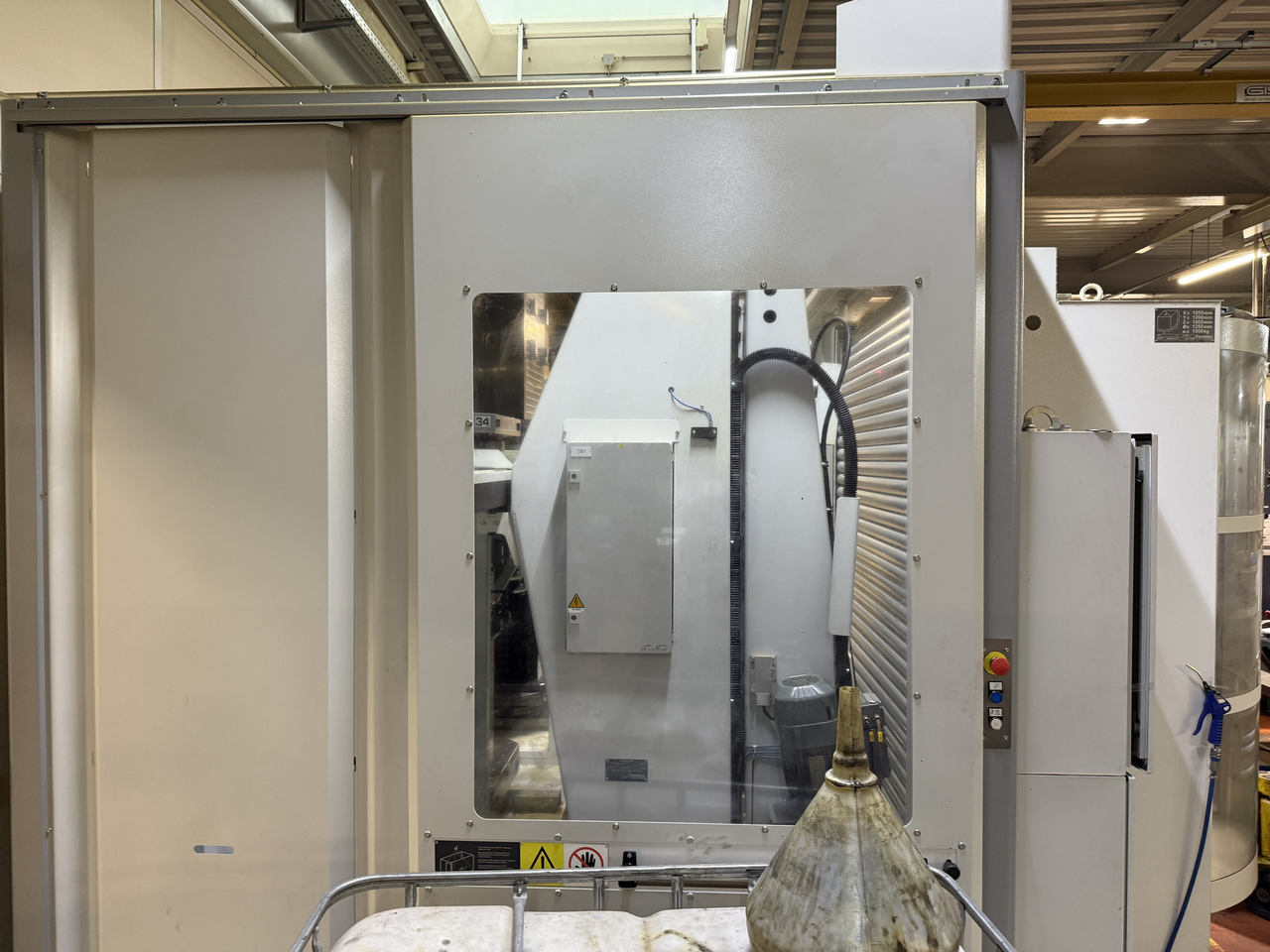

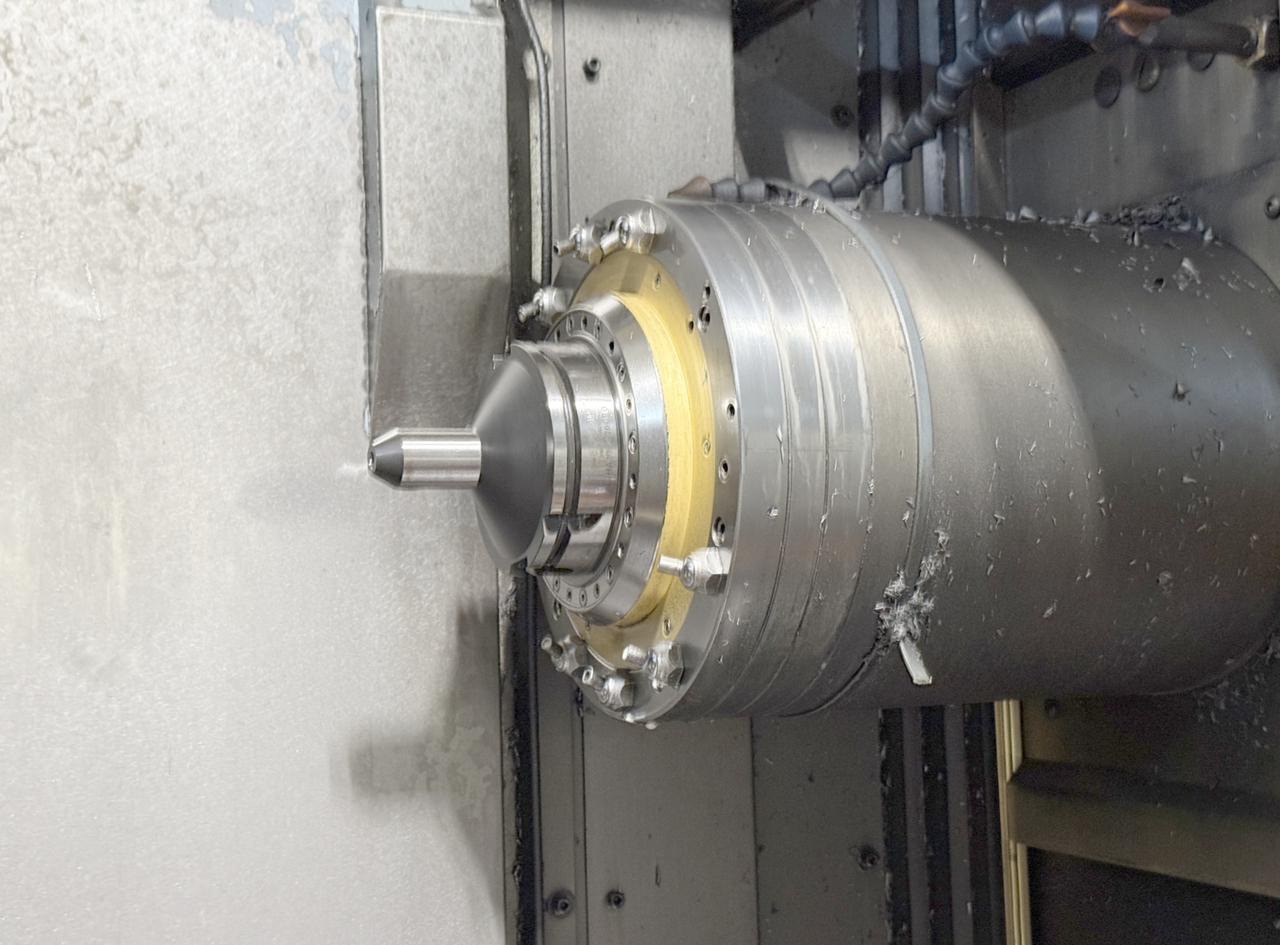

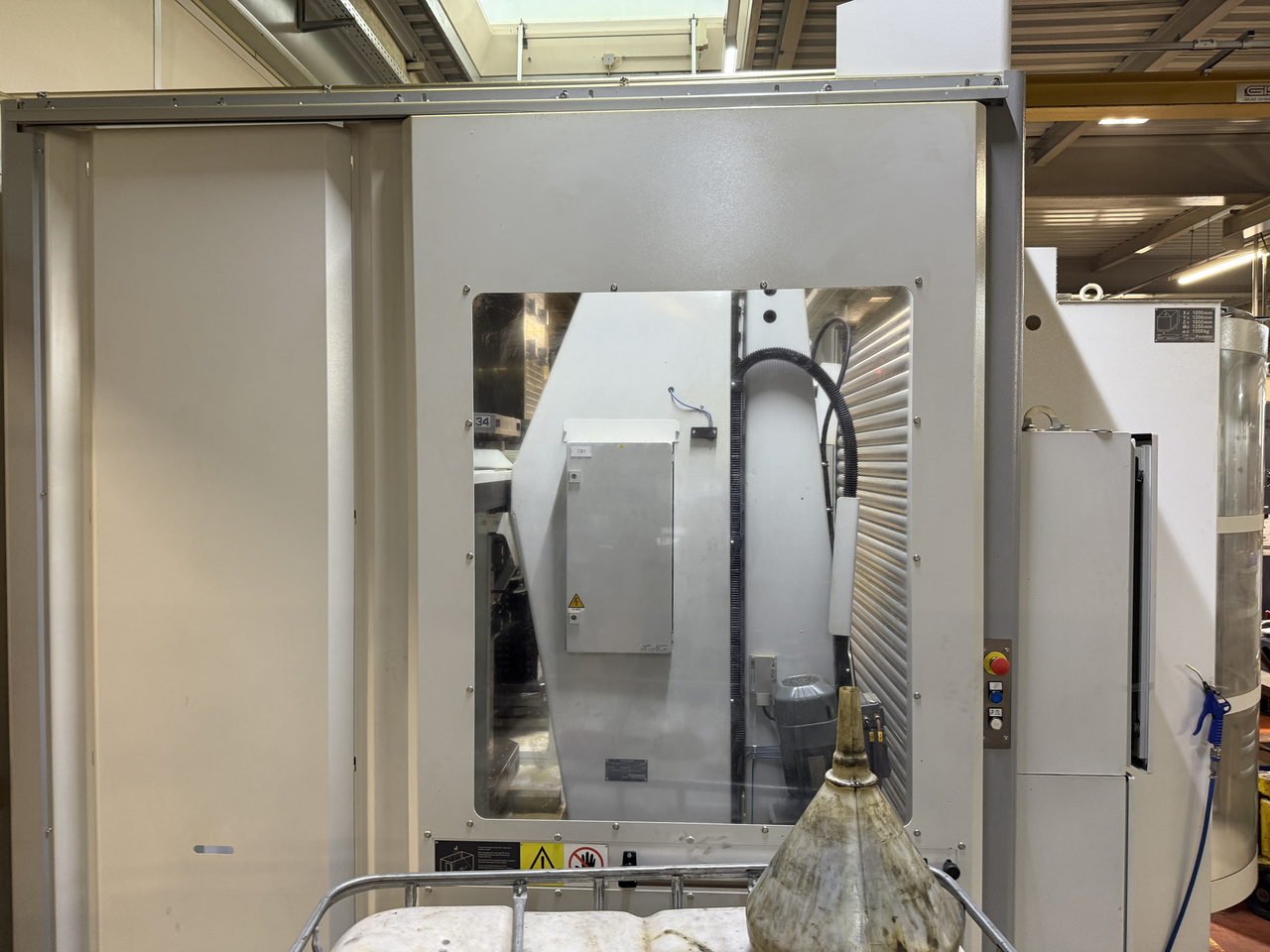

OKK HM 63

Type: HM 63

Manufacturer: OKK

Group: Machining center

Subgroup: 4-axis machining center

Control: FANUC Series 16i-MC

Stock: 023084

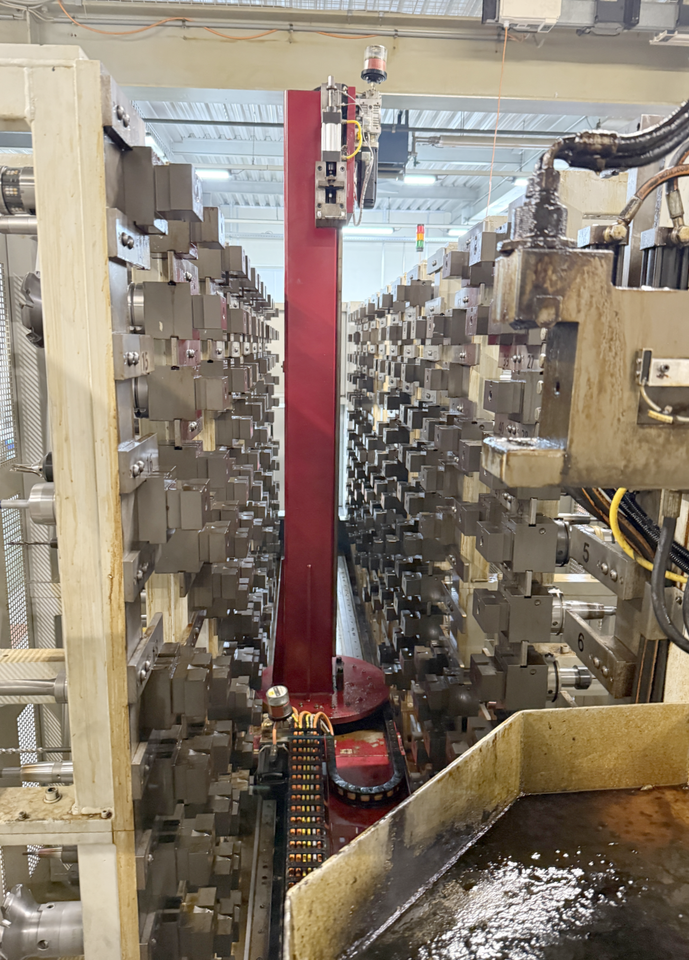

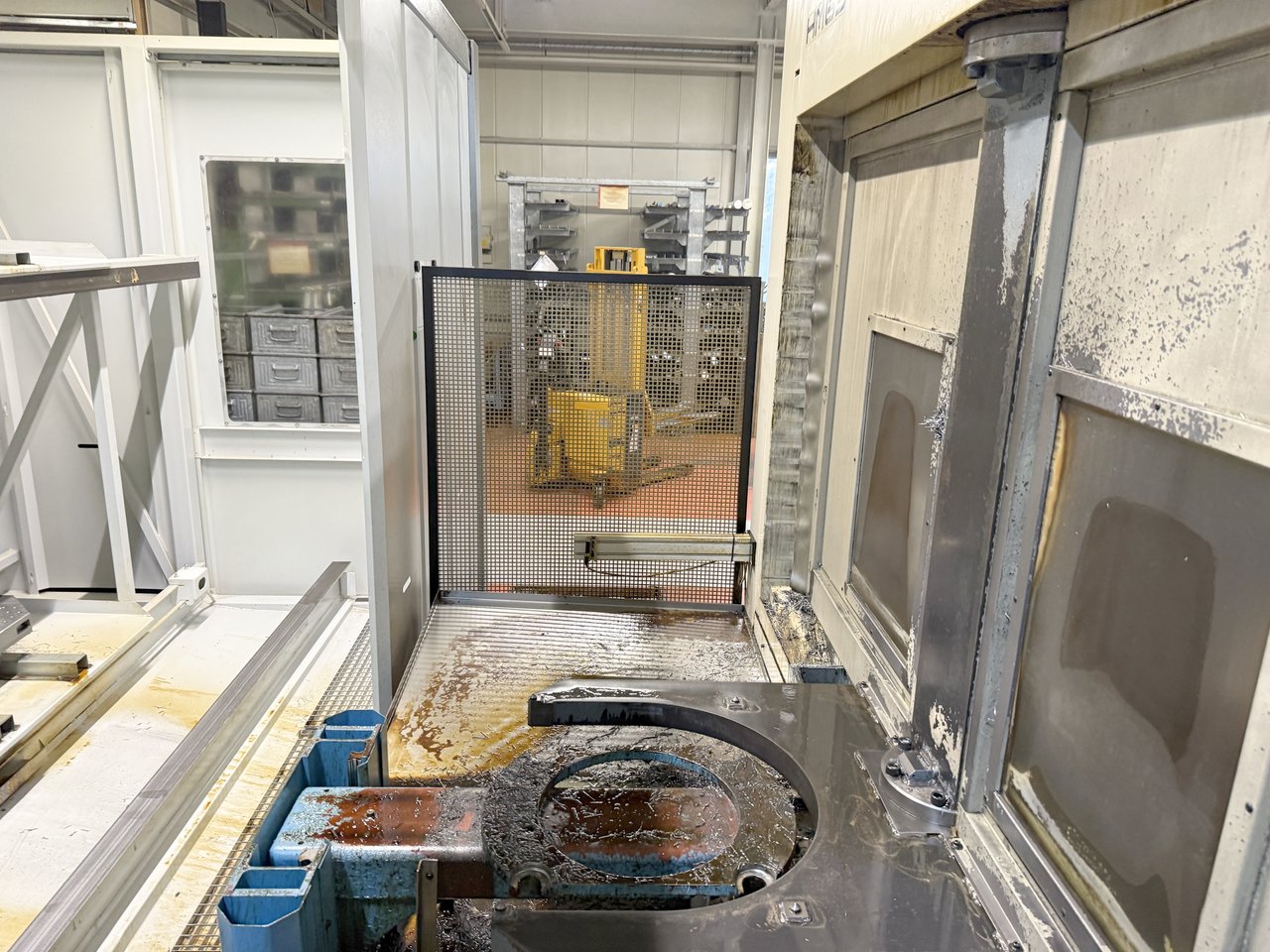

OKK HM 63 is a 4‑axis machining center designed for precision, high accuracy and reliable operation. Travels X620×Y560×Z560 mm; pallet 400×400 mm; max workpiece 450 kg. 40‑station changer, tool Ø 82 mm (140 with free pockets), length 300 mm, max tool 12 kg. BT40, nose‑to‑table 150–710 mm; spindle 30–16,000 rpm (2 steps); spindle motor 18.5/22 kW. Feed 1–40,000 mm/min, rapid 40 m/min; tool change 1.3 s; chip‑to‑chip 4 s; air 4–6 bar. Coolant 400 l; coolant‑through‑spindle 20 bar. Weight ~10,000 kg; dims 3940×2510×2900 mm. Suited for tight tolerances in automotive, aerospace, medical and tooling.

| Number of axis total | 4 |

| Longitudinal travel (X-axis) | 620 mm |

| Transversal travel (y-axis) | 560 mm |

| Vertical travel (z axis) | 560 mm |

| Pallets chanching device: | |

| numbers | |

| Length | 400 mm |

| Width | 400 mm |

| Maximum workpiece weight | 450 kg |

| Tool changer: | |

| Number of tools | 40 |

| Tool diameter max. | 82 mm |

| Diameter with free adjacent pockets | 140 mm |

| Tool lenght | 300 mm |

| Max. tool-weight | 12 kg |

| Time of tool changing | 1.3 s |

| Average chip-to-chip time | 4 s |

| Spindle nose: BT | 40 |

| Distance spindle nose to table | 150 - 710 mm |

| Spindle speeds: | |

| number (steps) | 2 |

| from | 30 t/min |

| up to | 16000 t/min |

| Feed range | 1 - 40000 mm/min |

| Rapid traverse: | 40 m/min |

| Air connect | 4 - 6 bar |

| Spindle motor | 18.5 / 22 kW |

| Machine's weight about | 10000 kg |

| Overall dimensions machine: | |

| Length | 3940 mm |

| Width | 2510 mm |

| Height | 2900 mm |

| Various accessories: | |

| Coolant system | 400 l |

| Coolant through spindle (cts) | 20 bar |

| Chip conveyor | |

| Status light |

Need Assistance? Just WhatsApp Us!

Need Assistance? Just WhatsApp Us!