1

/

of

11

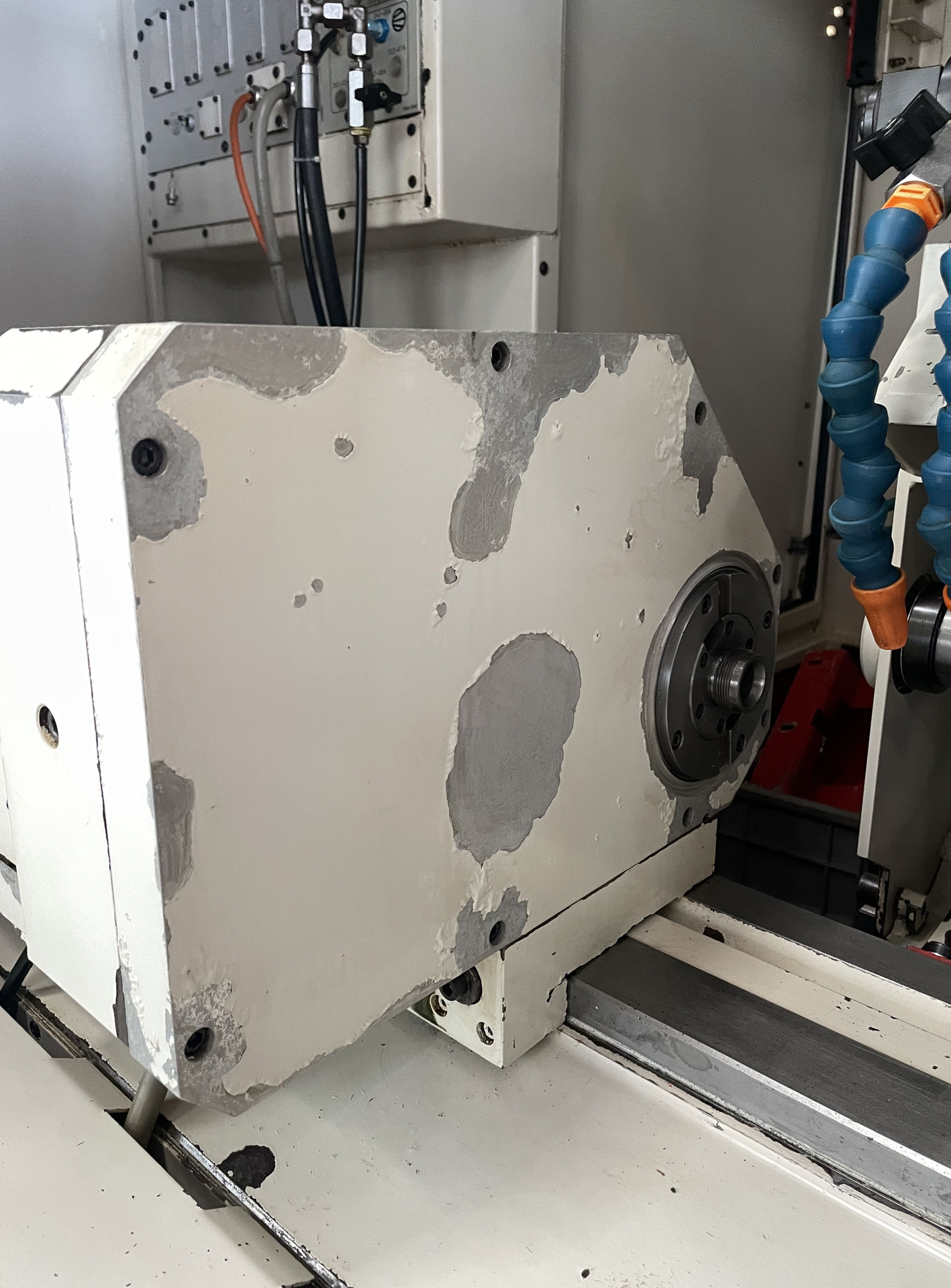

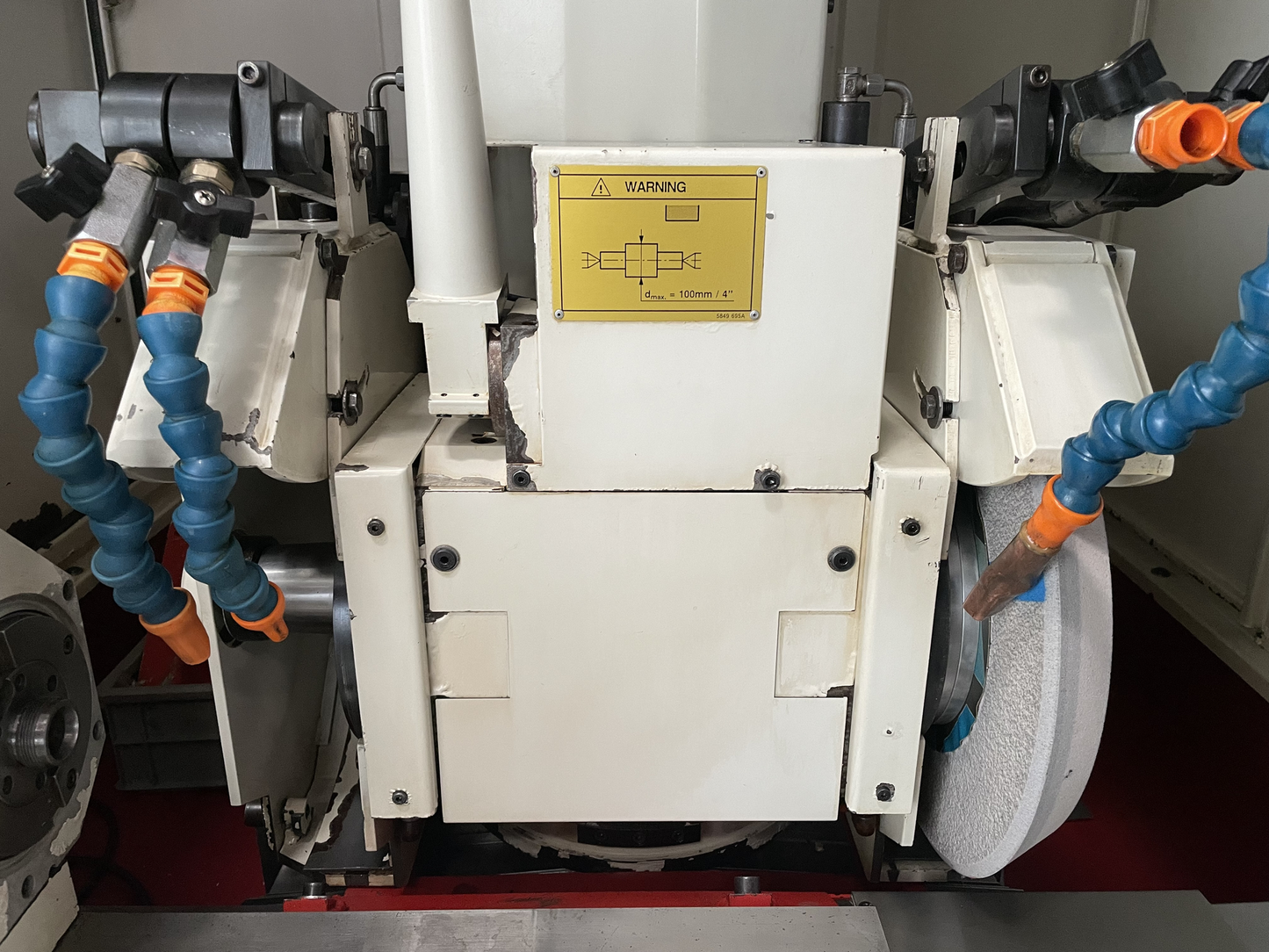

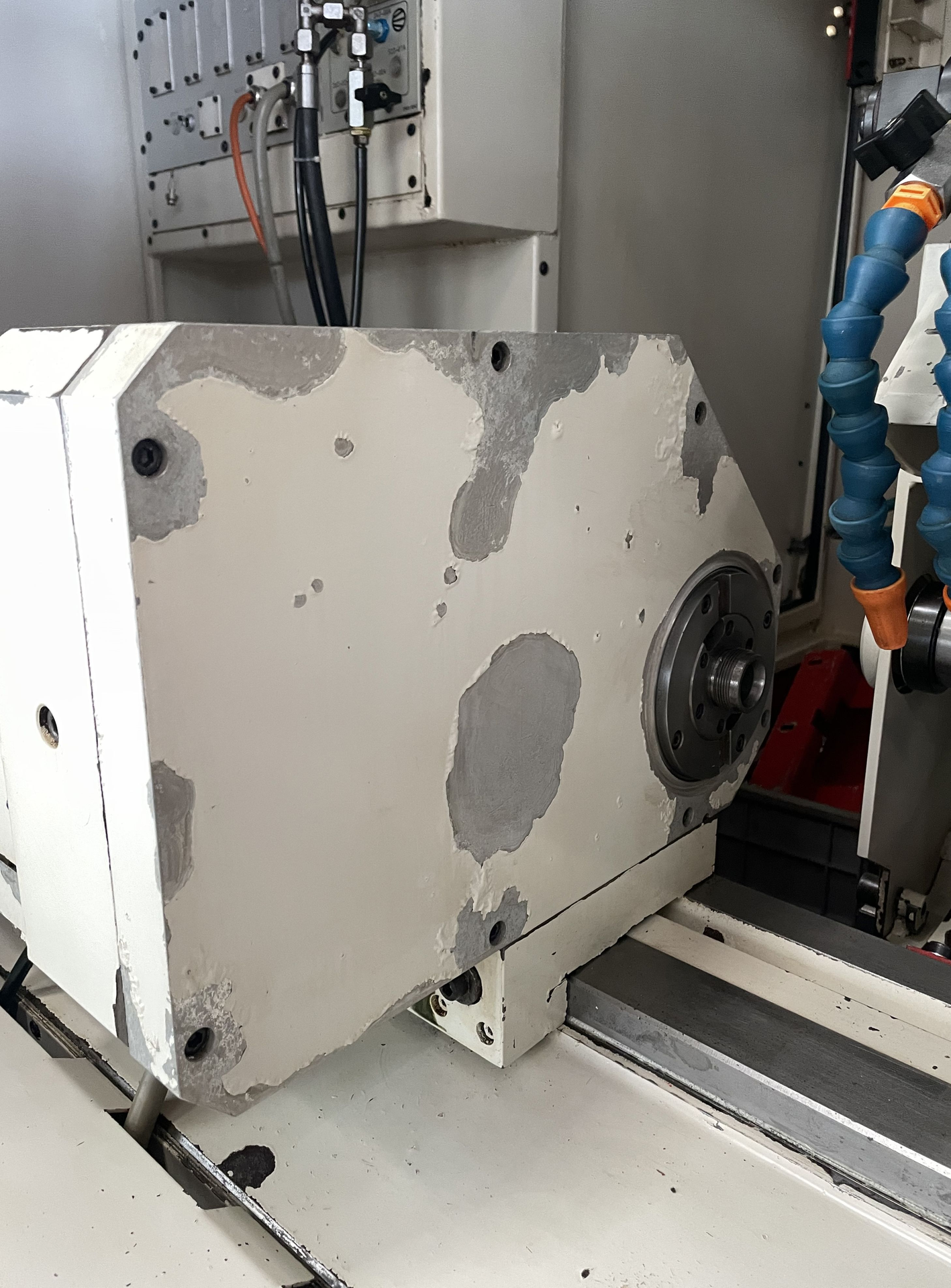

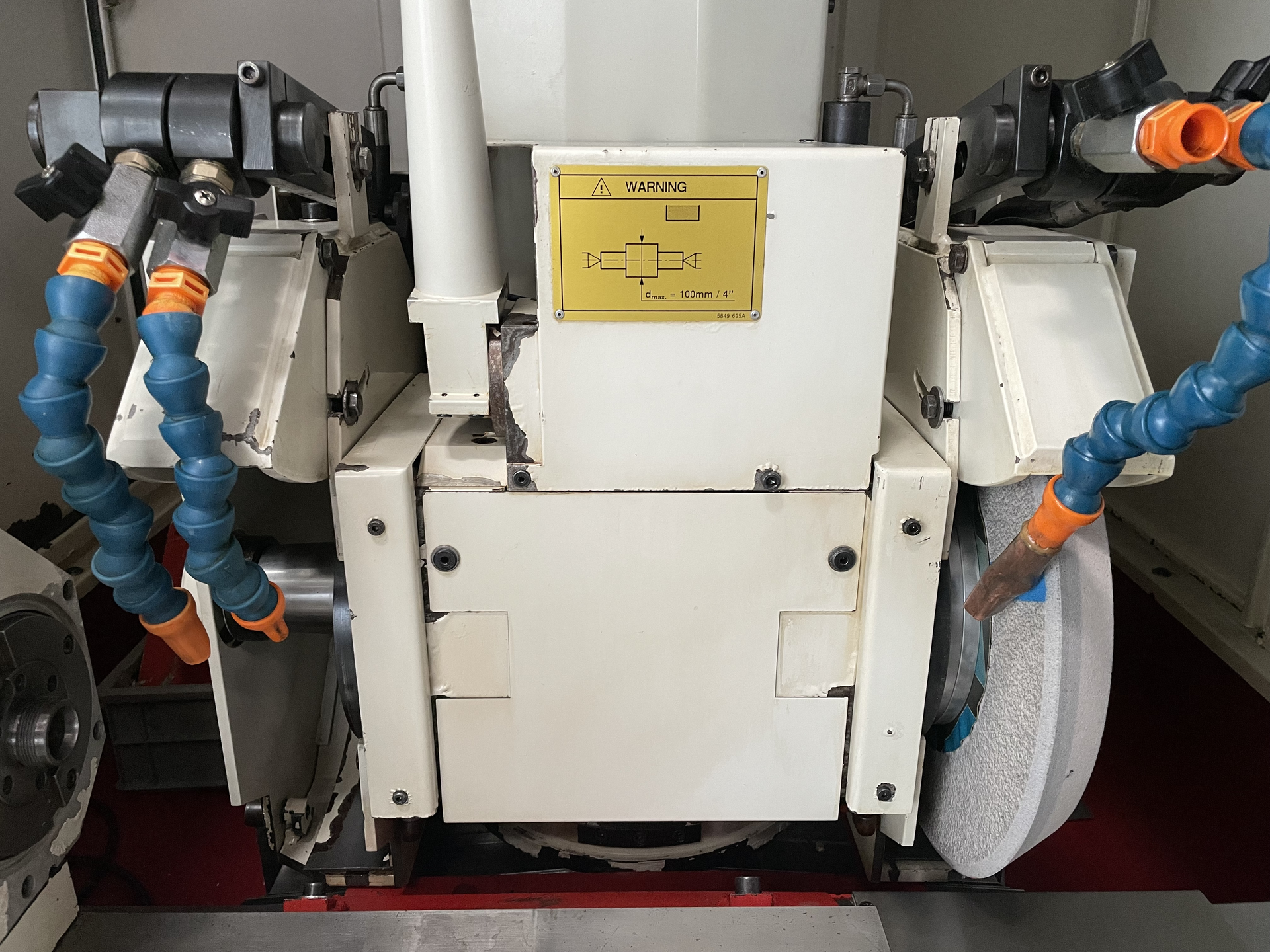

STUDER S 21 lean CNC

Type: S 21 lean CNC

Manufacturer: STUDER

Group: CNC cylindrical grinder

Subgroup: CNC cylindrical grinder

Control: GE FANUC Series 21i-T

Stock: 022666

STUDER S 21 lean CNC is a CNC cylindrical grinder offering high precision, exceptional accuracy and reliable performance. Centre height 125 mm, distance between centres 400 mm, max workpiece 30 kg; grinding wheels Ø400×40 mm (L/R); B axis -15/+195° resolution 1°; peripheral wheel speed 35 m/s; cross travel 254 mm; longitudinal travel 483 mm; feed 0.001–5000 mm/min; table speed 0.001–10000 mm/min; work spindle stepless 1–1500 t/min, spindle hole 26 mm, taper MT/CM 4. Grinding spindle motor 3 kW; total power 20 kVA; 3x400 V 50 Hz; weight ~4300 kg; dims 2300×2000×2100 mm. Equipment: coolant system, magnetic separator, paper filtration, MARPOSS touch probe, MOVOMATIC CR257 measuring device, internal grinding attachment, 1 spindle, wheel speeds up to 60000 t/min, set of flanges, balancing support, lamp, CNC redressing cycle, hydraulic dresser, tailstock fine adjust, SENSITRON feed, FIBARON oil mist extractor. Delivers tight tolerances; typical sectors: automotive, watchmaking, toolmaking, aerospace, medical.

| Centre height | 125 mm |

| Distance between centres | 400 mm |

| Workpiece weight on centres max. | 30 kg |

| Grinding weehl left side: | |

| Diameter | 400 mm |

| Width | 40 mm |

| Grinding wheel right side: | |

| Diameter | 400 mm |

| Width | 40 mm |

| B axis resolution max. | 1 ° |

| B axis swivelling range | -15 / +195 ° |

| Grinding wheel speeds: | |

| Peripheral speed | 35 m/s |

| Cross travel CNC | 254 mm |

| Feed speed up | 0.001-5000 mm/min |

| Longitudinal slide: | |

| Max. travel | 483 mm |

| Work piece spindle head: | |

| stepless | |

| from | 1 t/min |

| up to | 1500 t/min |

| Spindle hole | 26 mm |

| taper in spindle: MT | 4 |

| Tailstock: | |

| Taper in tailstock: | 3 CM |

| Table speed: | |

| from | 0.001-10000 mm/min |

| Voltage 50 Hz 3x | 400 Volt |

| Grinding spindle motor | 3 kW |

| Total power required | 20 kVA |

| Machine's weight about | 4300 kg |

| Overall dimensions machine: | |

| Length | 2300 mm |

| Width | 2000 mm |

| Height | 2100 mm |

| Various accessories: | |

| Coolant system | |

| Magnetic separator | |

| Paper filtration system | |

| Touch probe MARPOSS | |

| Measuring device | MOVOMATIC CR257 |

| Internal grinding attachment: | |

| Number of spindles | 1 |

| Grinding wheel speeds: | |

| up to | 60000 t/min |

| Set of flanges | |

| Balancing support | |

| Lamp | |

| CNC cycle redressing unit | |

| Redressing attachment hydraulic | |

| Tailstock with fine adjustement | |

| Feed SENSITRON | |

| Oil mist extractor | FIBARON |

Need Assistance? Just WhatsApp Us!

Need Assistance? Just WhatsApp Us!