1

/

of

5

DOOSAN NHP 6300

Type: NHP 6300

Manufacturer: DOOSAN

Group: Machining center

Subgroup: Horizontal machining center

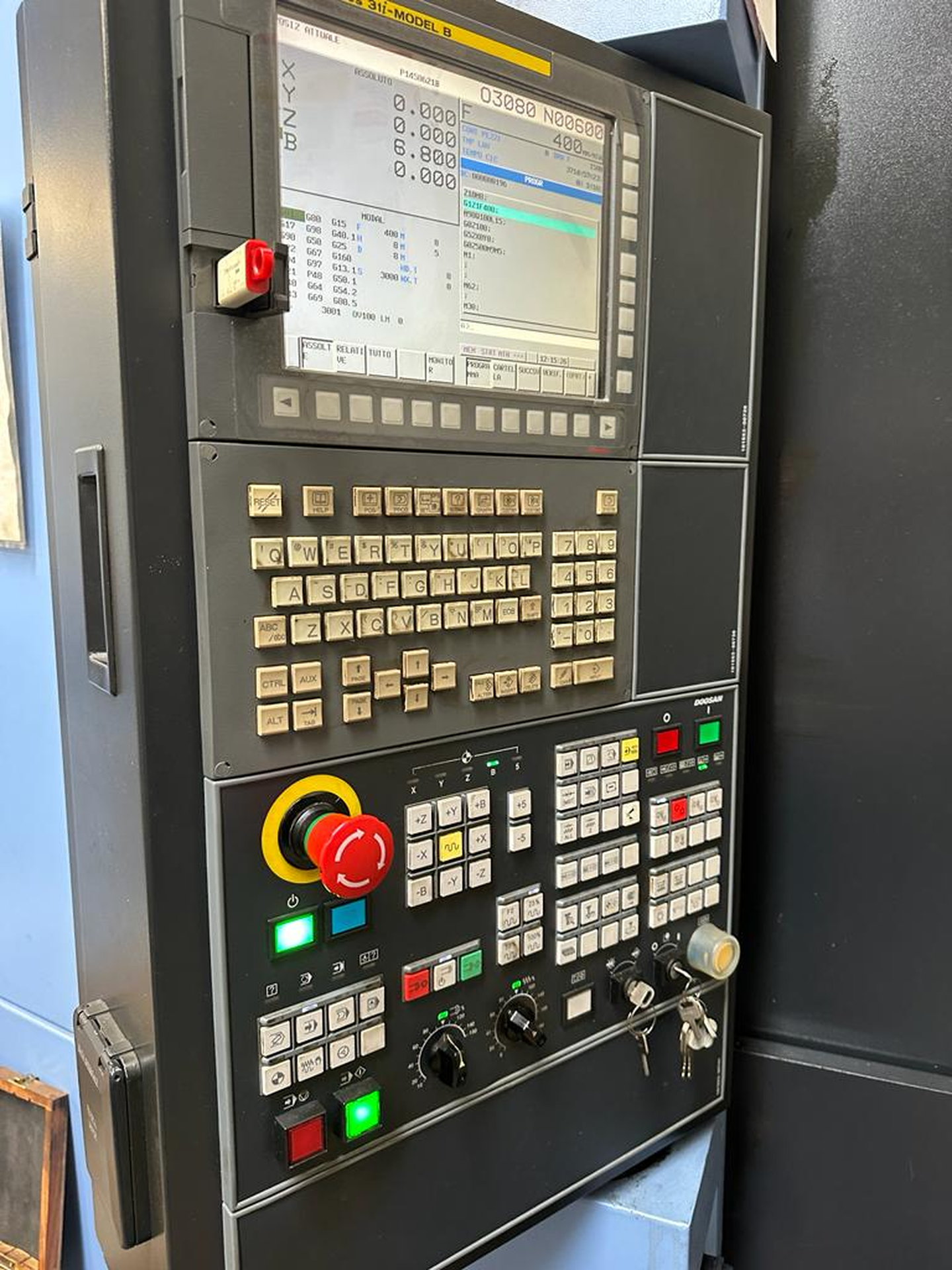

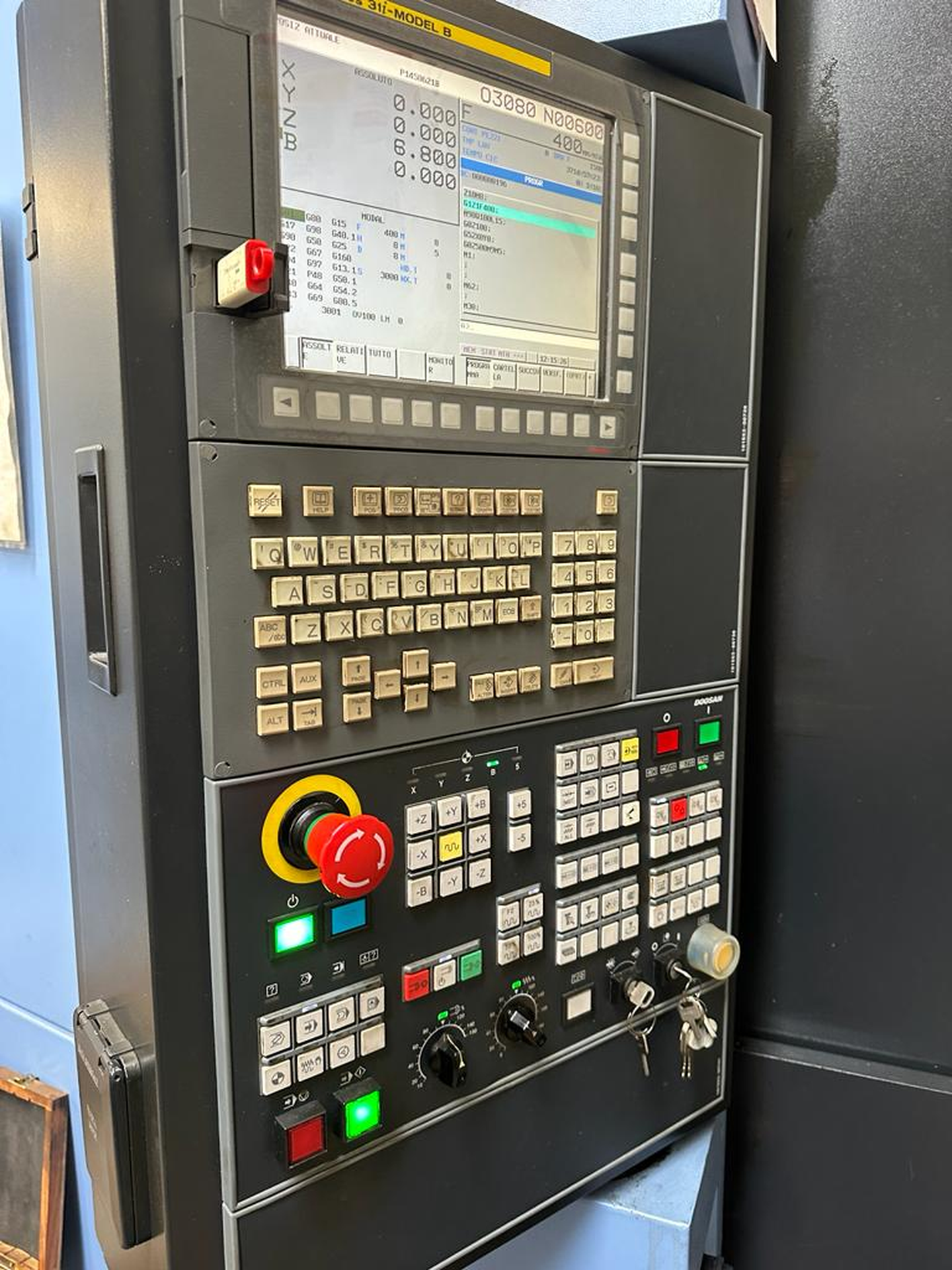

Control: GE FANUC Series 31i-Model B

Year: 2015

Stock: 022657

DOOSAN NHP 6300 is a Horizontal machining center of high precision, engineered for excellent accuracy and reliability. Travels X 1050 mm, Y 900 mm, Z 1000 mm; 2 pallets 630×630 mm; max workpiece weight 1500 kg; height 1350 mm; diameter 1050 mm; table division B 1°. Spindle ISO 50, stepless 40–10,000 rpm; spindle power 18.5/22 kW; rapid traverse 60 m/min; supply 3×400 V 50 Hz; machine weight ≈18,000 kg; footprint L7410×W3930×H3479 mm. Tool magazine 60 positions, tool change 2 s, chip-to-chip 5 s, pallet change 12 s; coolant capacity 925 l; coolant-through-spindle 70 bar. Enables tight tolerances; ideal for automotive, aerospace, medical and machine-tool sectors.

| Longitudinal travel (X-axis) | 1050 mm |

| Transversal travel (y-axis) | 900 mm |

| Vertical travel (z axis) | 1000 mm |

| Dimension of the workpice: | |

| Height | 1350 mm |

| Diameter | 1050 mm |

| Table divisions (B) | 1 ° |

| Pallets chanching device: | |

| numbers | 2 |

| Length | 630 mm |

| Width | 630 mm |

| Maximum workpiece weight | 1500 kg |

| Time of changing palets | 12 s |

| Tool magazine number of tool places | 60 |

| Tool diameter max. | 125 mm |

| Diameter with free adjacent pockets | 320 mm |

| Tool lenght | 630 mm |

| Max. tool-weight | 25 kg |

| Time of tool changing | 2 s |

| Average chip-to-chip time | 5 s |

| Spindle nose: ISO | 50 |

| Distance from horizontal | |

| spindle to table | 75 - 975 mm |

| Spindle speeds: | |

| stepless | |

| from | 40 t/min |

| up to | 10000 t/min |

| Rapid traverse: | 60 m/min |

| Voltage 50 Hz 3x | 400 Volt |

| Spindle power | 18.5 / 22 kW |

| Machine's weight about | 18000 kg |

| Overall dimensions machine: | |

| Length | 7410 mm |

| Width | 3930 mm |

| Height | 3479 mm |

| Various accessories: | |

| Coolant system | 925 l |

| Coolant through spindle (cts) | 70 bar |

Need Assistance? Just WhatsApp Us!

Need Assistance? Just WhatsApp Us!