1

/

of

7

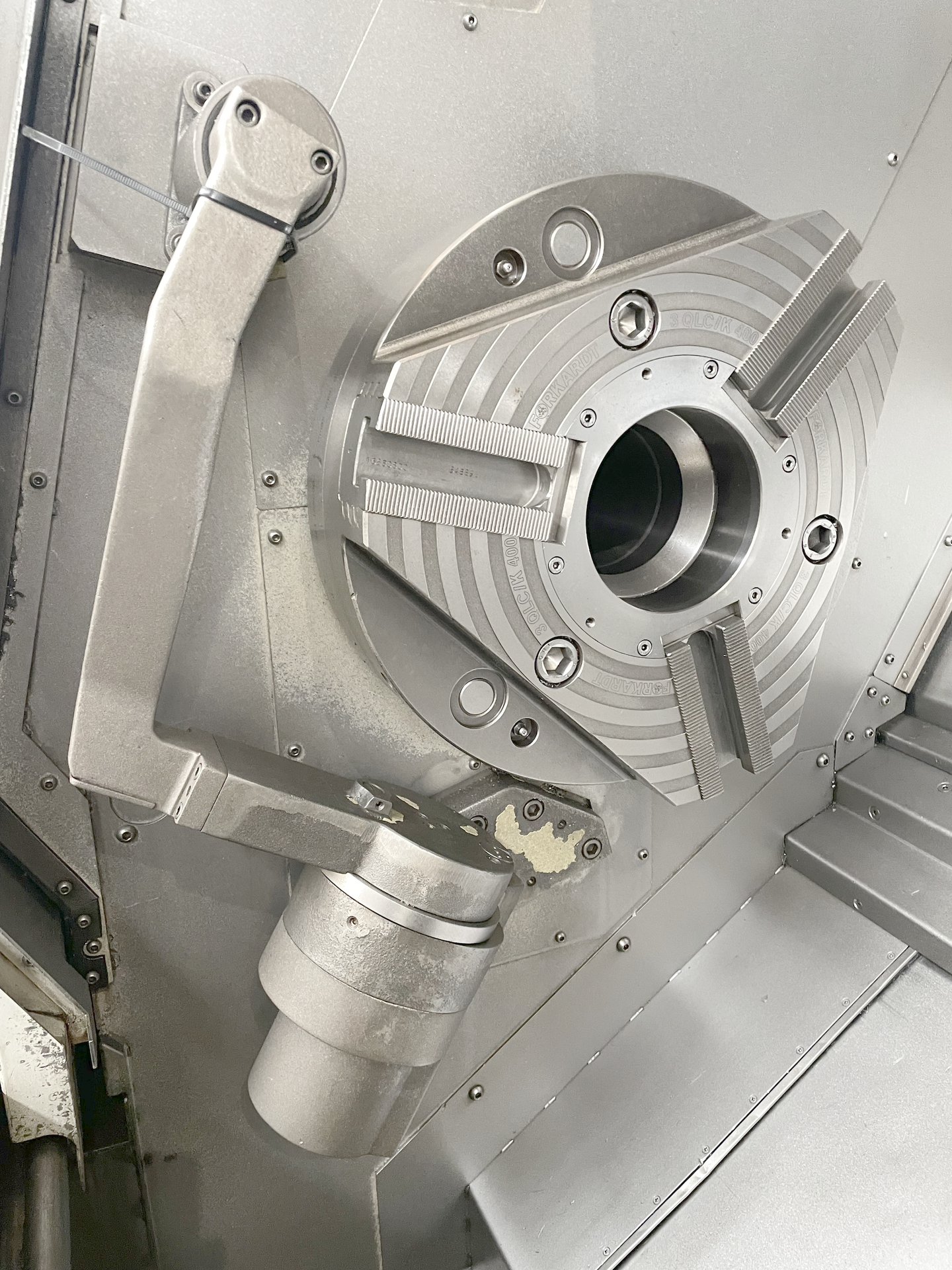

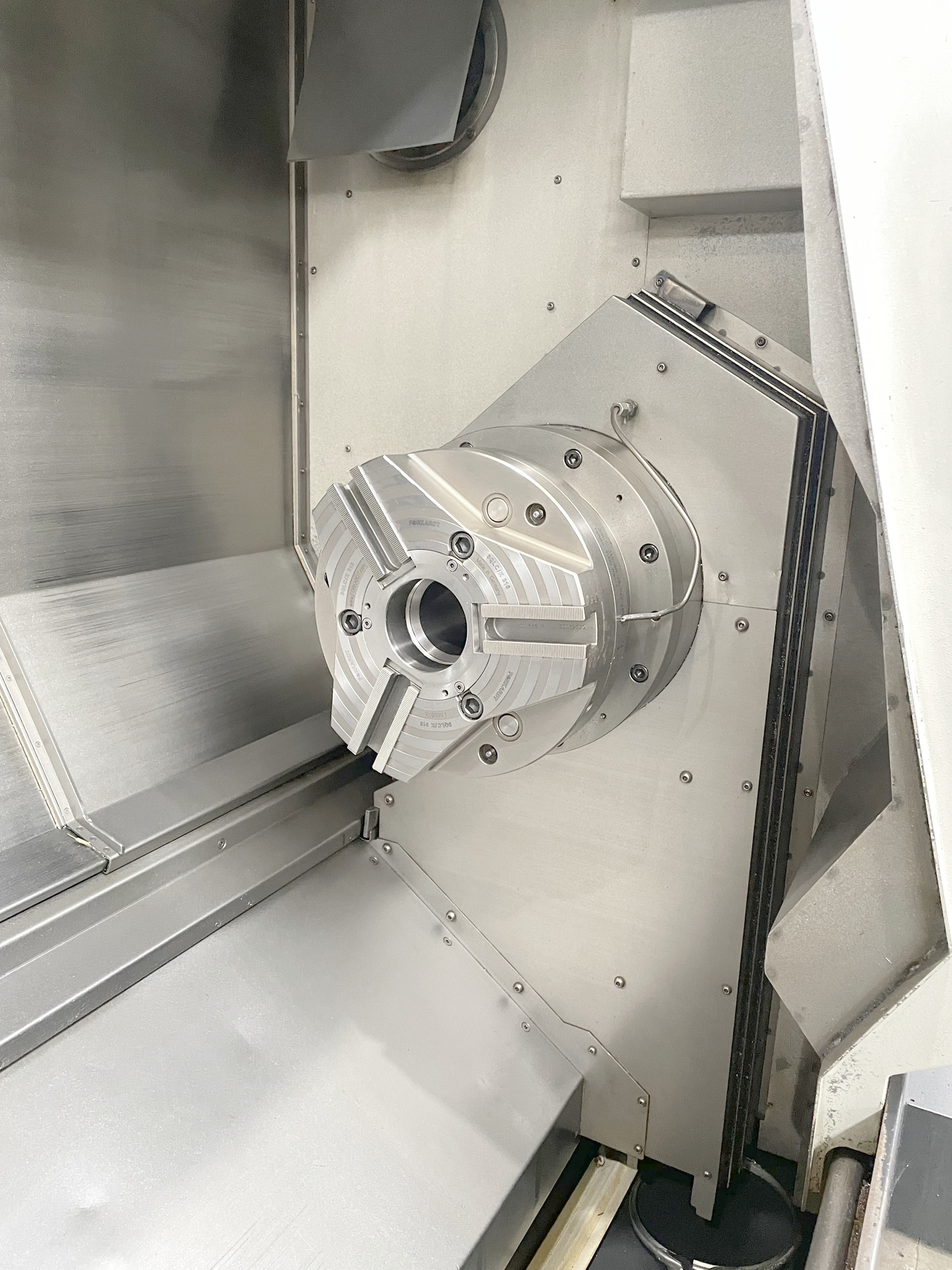

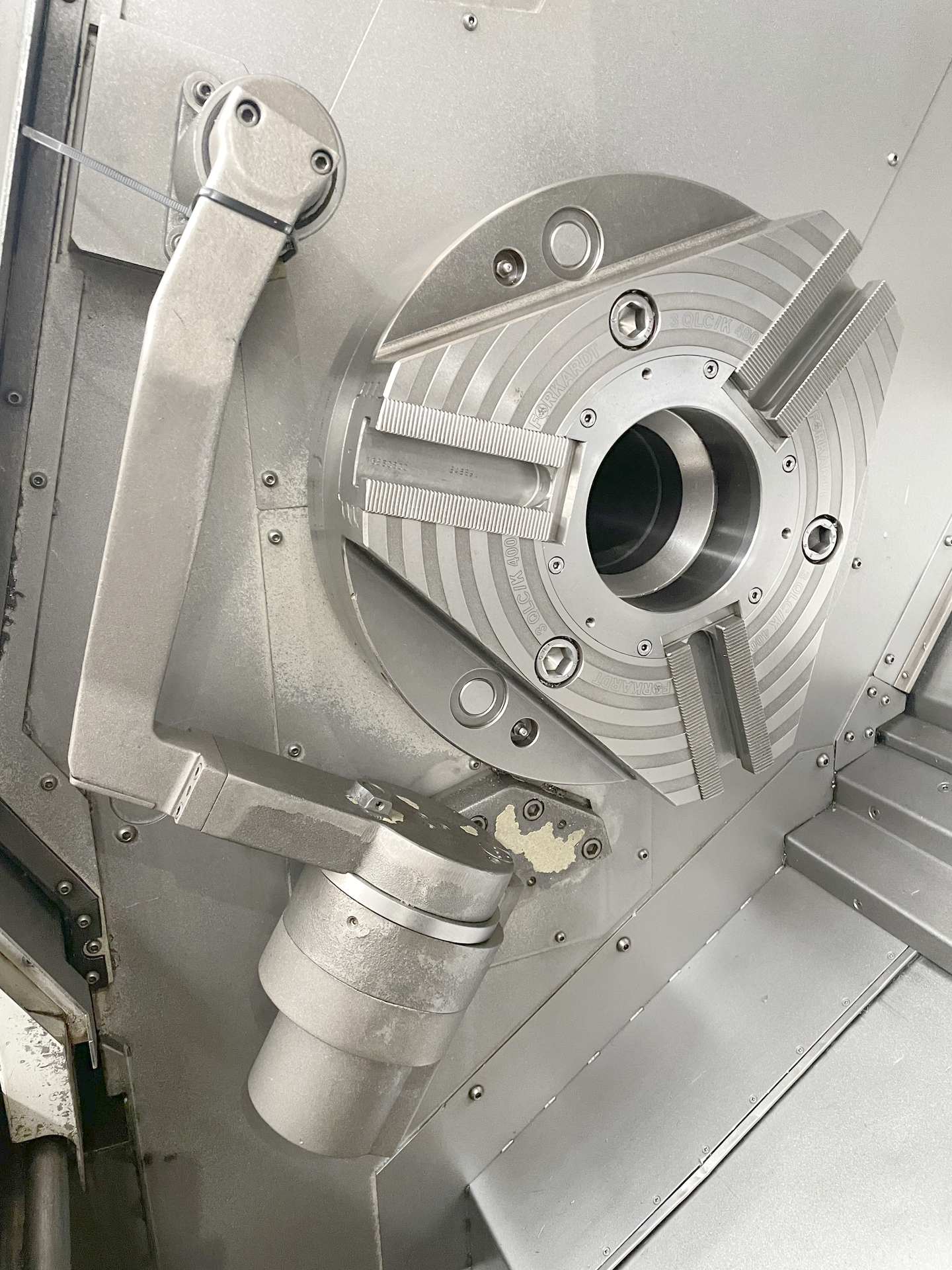

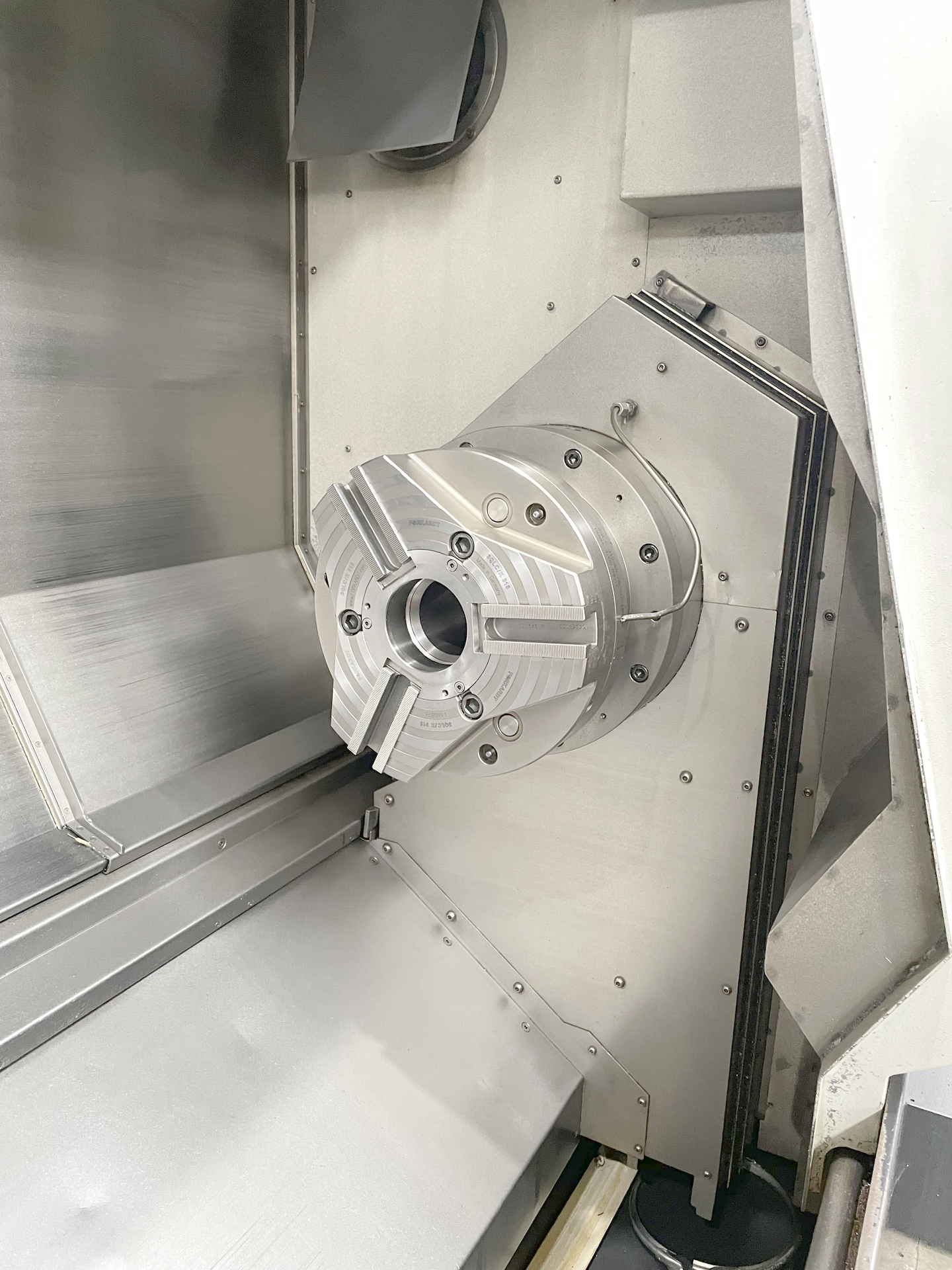

MAZAK INTEGREX 400-3S

Type: INTEGREX 400-3S

Manufacturer: MAZAK

Group: CNC turning lathe

Subgroup: CNC Turning-Milling-Drilling Center

Control: Mazatrol PC Fusion CNC 640MT Pro

Year: 2004

Stock: 022586

MAZAK INTEGREX 400-3S is a CNC Turning-Milling-Drilling Center designed for precision, high accuracy and reliability. Capacities: distance between centres 1500 mm, swing 760 mm, max turning length 1524 mm, bar passage 102/77 mm, tool magazine 40 stations (Ø max 90 mm, L 400 mm). Main specs: main spindle A2-8 stepless 35–3300 t/min 30 kW 1200 Nm; back spindle A2-8 35–4000 t/min 26/22 kW 500 Nm; milling spindle CAPTO C6 15–12000 t/min 18.5 kW 120 Nm. Travels X630 Y±115 Z1585 mm; feeds 0–8000 mm/min; rapid X/Z 38 m/min Y26 m/min; weight ~13300 kg; footprint 5110x2196 mm; height 2798 mm. Equipment: coolant 444 l (15 bar through milling spindle), Forkhardt 3-jaw chucks Ø400/315 mm, linear scale for X, RS232, PCMCIA, spindle sync, chip conveyor, synchronized tapping, foot pedal. Enables tight tolerances; typical applications: automotive, aerospace, medical, machine tools, watchmaking.

| Number of axis total | 6 |

| Number of spindles | 2 |

| Number of milling heads | 1 |

| Distance between centres | 1500 mm |

| Swing diameter | 760 mm |

| Maximum turning length | 1524 mm |

| Max. turning diameter | 760 mm |

| Max. bar diameter | 102 / 77 mm |

| Tool magazine number of tool places | 40 |

| Tool diameter max. | 90 mm |

| Diameter with free adjacent pockets | 125 mm |

| Tool lenght | 400 mm |

| Main spindle: | |

| Spindle nose | A2-8 |

| Internal spindle diameter | 112 mm |

| C axis (spindle,resolution) | 0.001 ° |

| Spindle speeds: | |

| stepless | |

| from | 35 t/min |

| up to | 3300 t/min |

| Spindle power | 30 kW |

| Torque max. | 1200 Nm |

| Back spindle: | |

| Spindle nose | A2-8 |

| Spindle hole | 88 mm |

| max. speed | 35 - 4000 t/min |

| C axis (spindle,resolution) | ° |

| Power of back spindle | 26 / 22 kW |

| Torque max. | 500 Nm |

| Milling spindle: | |

| Milling spindle receptacle | CAPTO C6 |

| Milling cutter speeds | 15 - 12000 t/min |

| Spindle torque | 120 Nm |

| Drive milling spindle | 18.5 kW |

| B axis swivelling range | -30 / +195 ° |

| B axis resolution max. | ° |

| Travels: | |

| X axis | 630 mm |

| Y axis | + / - 115 mm |

| Z axis | 1585 mm |

| Feeds | 0 - 8000 mm/min |

| Rapid traverse X | 38 m/min |

| Rapid traverse Z | 38 m/min |

| Rapid traverse Y | 26 m/min |

| Time under power | 35000 Heures |

| Machine's weight about | 13300 kg |

| Required floor space | 5110 x 2196 mm |

| Overall dimensions machine: | |

| Height | 2798 mm |

| Various accessories: | |

| Linear scale system for X-axis | |

| 3-jaw chuck diameter | Forkhardt 400 mm |

| 3-jaw chuck diameter (back spindle) | Forkhardt 315 mm |

| Hydraulic chuck | |

| Lamp | |

| Spindle blow out (backspindle) | |

| Air blast through milling spindle | |

| Coolant system | 444 l |

| Coolant through the milling head | 15 bar |

| Main and back spindle synchronization | |

| Interface serial port RS 232 | |

| Interface PCMCIA card | |

| Synchronized tapping | |

| Chip conveyor | |

| Foot pedal |

Need Assistance? Just WhatsApp Us!

Need Assistance? Just WhatsApp Us!