1

/

of

6

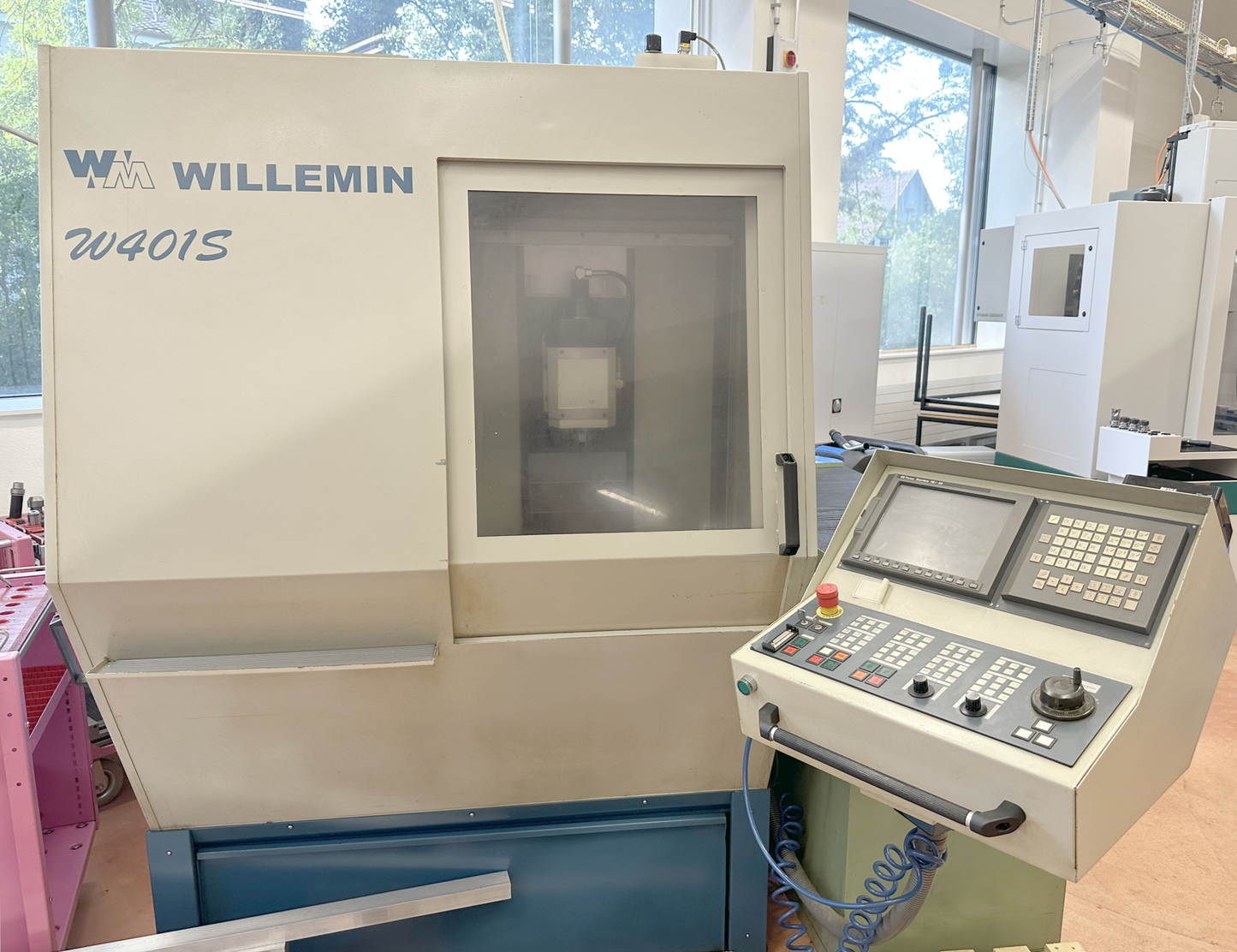

WILLEMIN MACODEL W 401S

Type: W 401S

Manufacturer: WILLEMIN MACODEL

Group: Machining center

Subgroup: 3-axis machining center

Control: GE FANUC Series 16i-M

Year: 2000

Stock: 022538

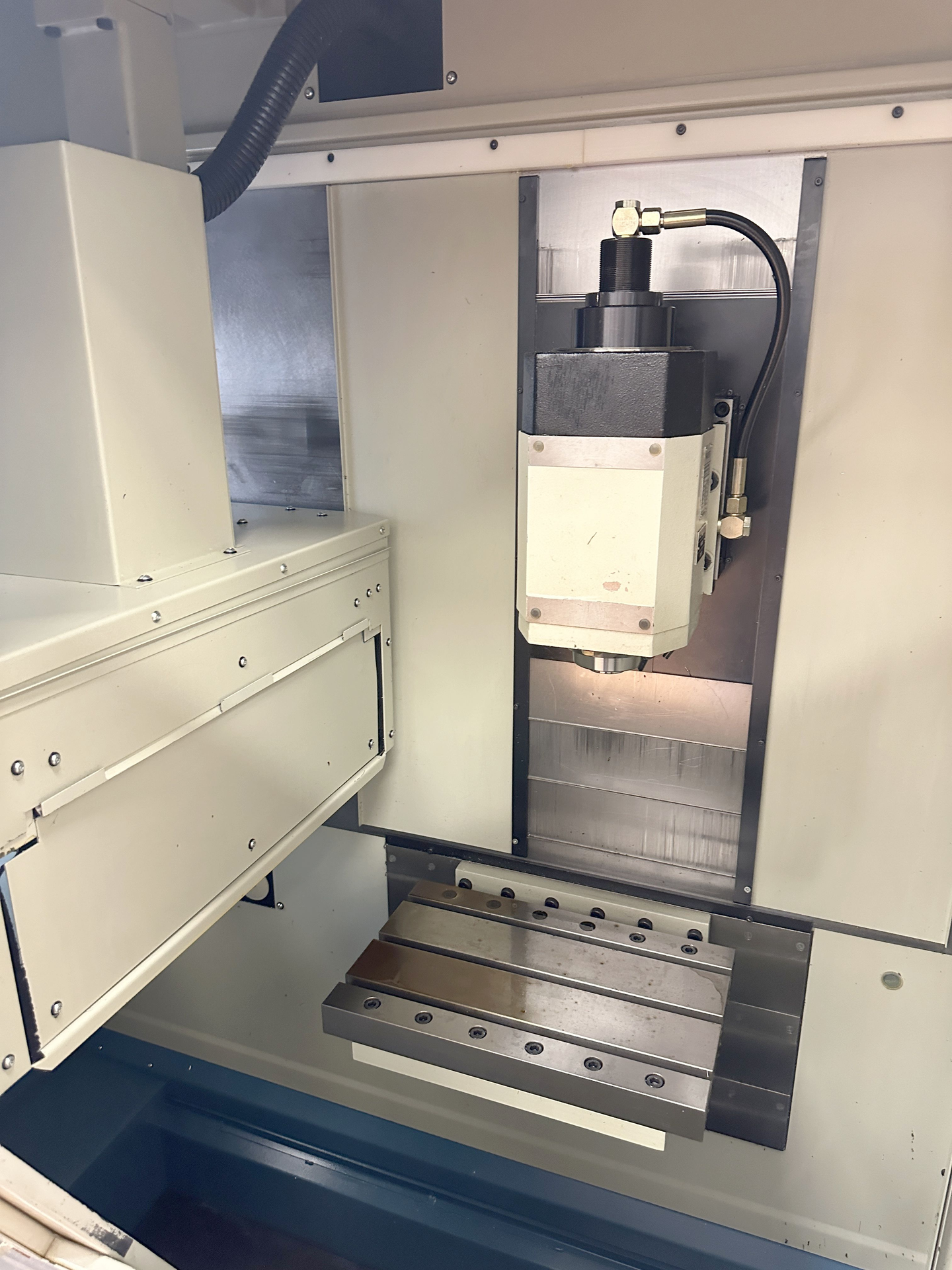

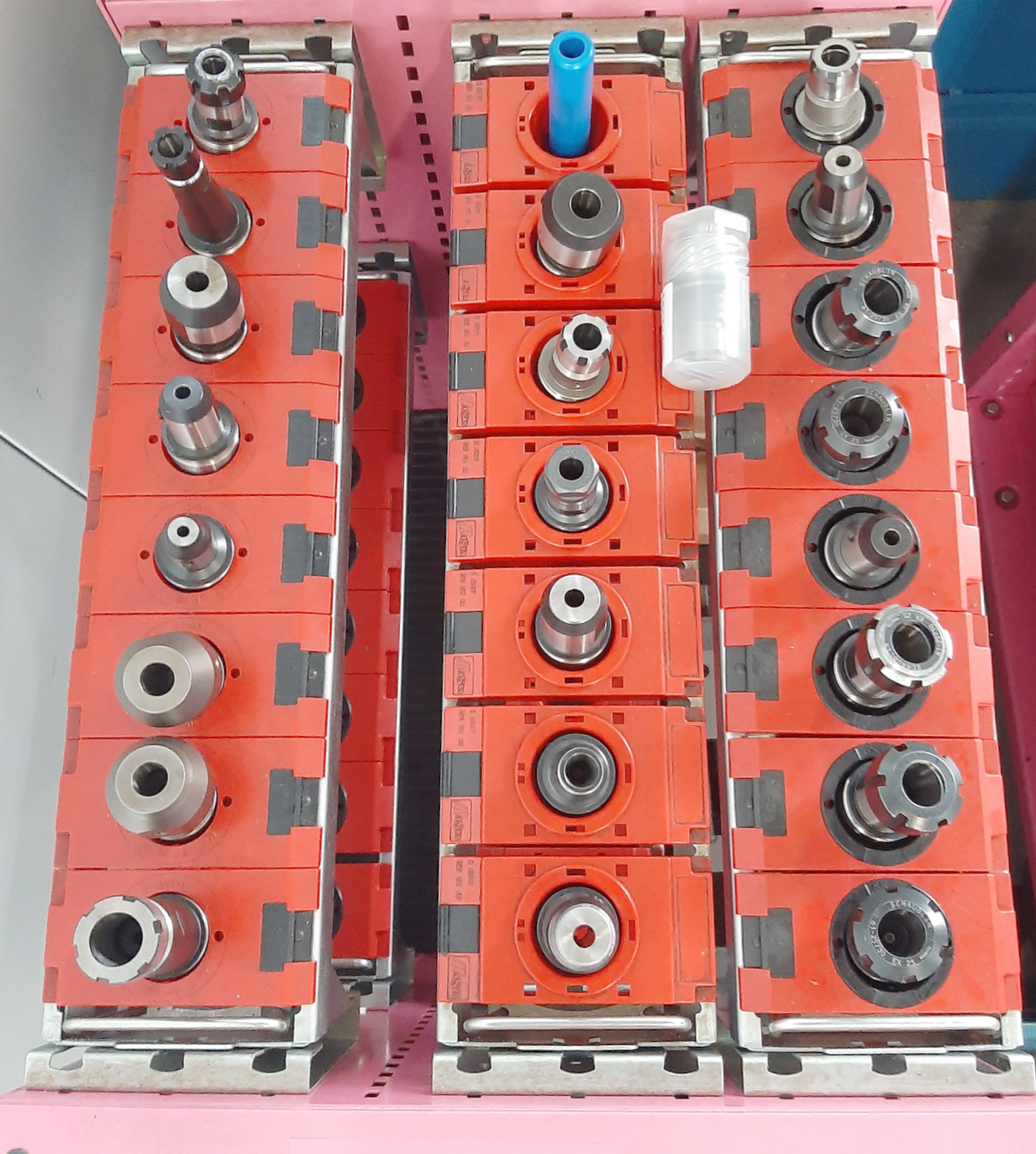

WILLEMIN MACODEL W 401S is a 3-axis machining center, engineered for precision, high accuracy and reliability. Capacities: table 400×250 mm, 3 T‑slots (80 mm spacing, 14 mm width), travels X250 Y200 Z300 mm. Specs: tool magazine 48 places, HSK E40 spindle, stepless 0–14,000 rpm, spindle power 10.4 kW; work feed 20 m/min, rapid 30 m/min, max feed force 3700 N, resolution 1 µm. Connections: air 6 bar, 3x400 V 50 Hz, total power 18 kVA; weight ≈1700 kg; dimensions 2100×1630×2265 mm (~2 m2 footprint). Accessories: vice (jaw width 100 mm), set of toolholders, coolant system, lamp. Suited for tight tolerances in automotive, watchmaking, machine tools, aerospace and medical sectors

| Number of axis total | 3 |

| Table length | 400 mm |

| Table width | 250 mm |

| Number of T-channels | 3 |

| Distance of the T-slots | 80 mm |

| T-channel width | 14 mm |

| Longitudinal travel (X-axis) | 250 mm |

| Transversal travel (y-axis) | 200 mm |

| Vertical travel (z axis) | 300 mm |

| Tool changer: | |

| Tool magazine number of tool places | 48 |

| Spindle nose: HSK | E40 |

| Spindle speeds: | |

| stepless | |

| from | 0 t/min |

| up to | 14000 t/min |

| Work feed rate | 20 m/min |

| Rapid traverse: | 30 m/min |

| Max. Feed force | 3700 N |

| Resolution | 1 µm |

| Air connect | 6 bar |

| Voltage 50 Hz 3x | 400 Volt |

| Spindle power | 10.4 kW |

| Total power required | 18 kVA |

| Machine's weight about | 1700 kg |

| Overall dimensions machine: | |

| Length | 2100 mm |

| Width | 1630 mm |

| Height | 2265 mm |

| Space requirement env. | 2 m2 |

| Various accessories: | |

| Vice: width | 100 mm |

| Set of toolholders | |

| Coolant system | |

| Lamp |

Need Assistance? Just WhatsApp Us!

Need Assistance? Just WhatsApp Us!