1

/

of

13

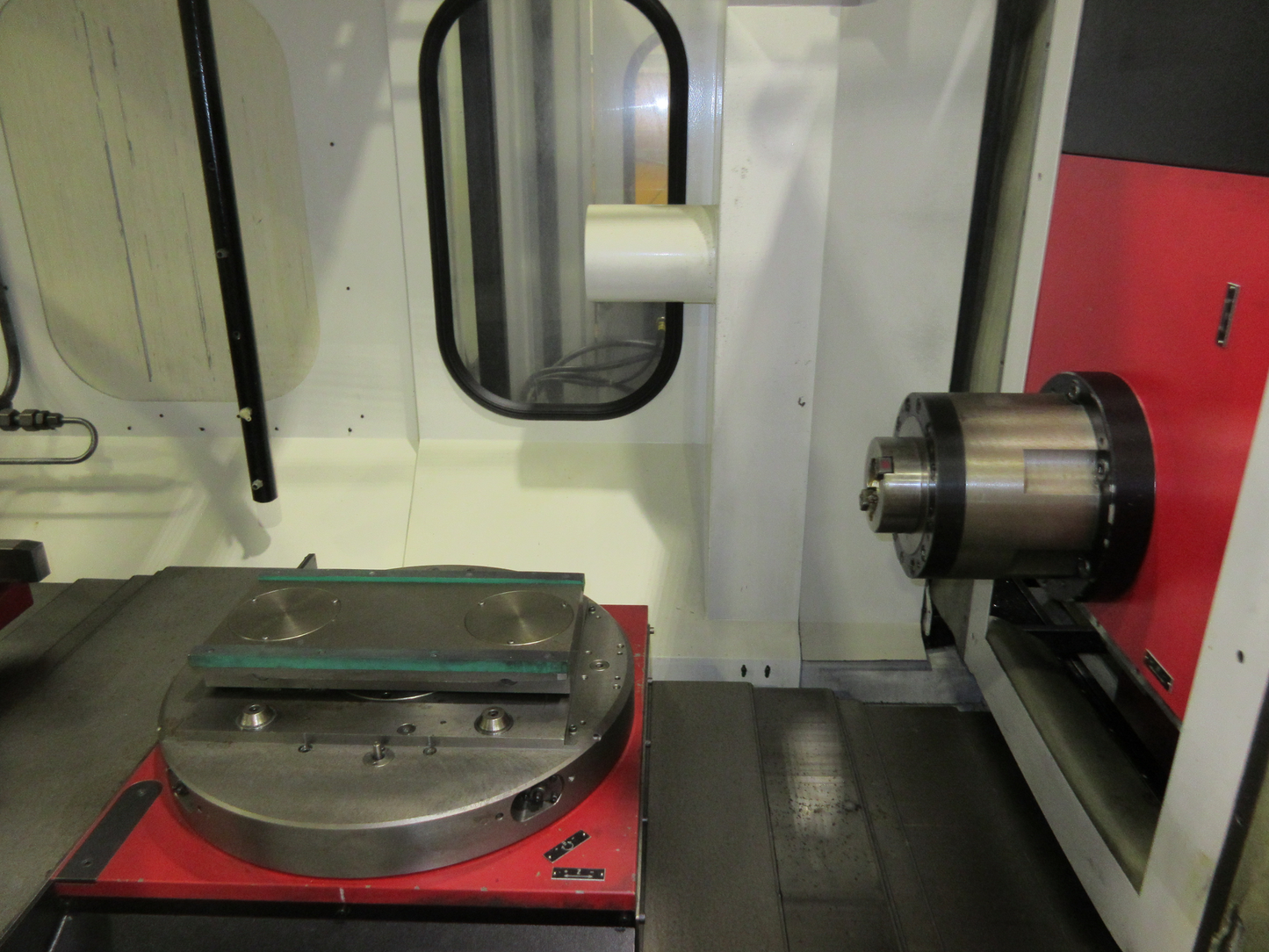

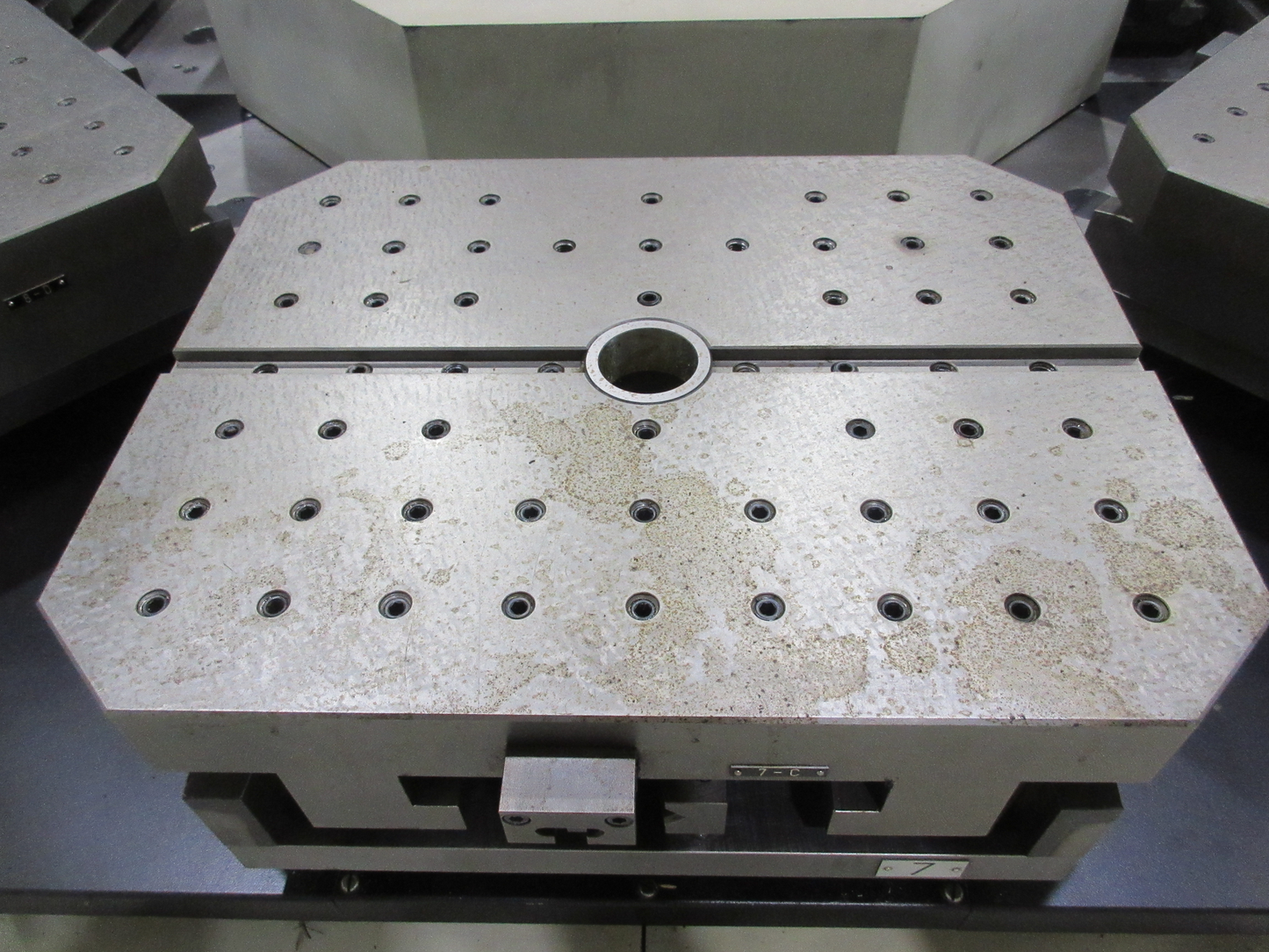

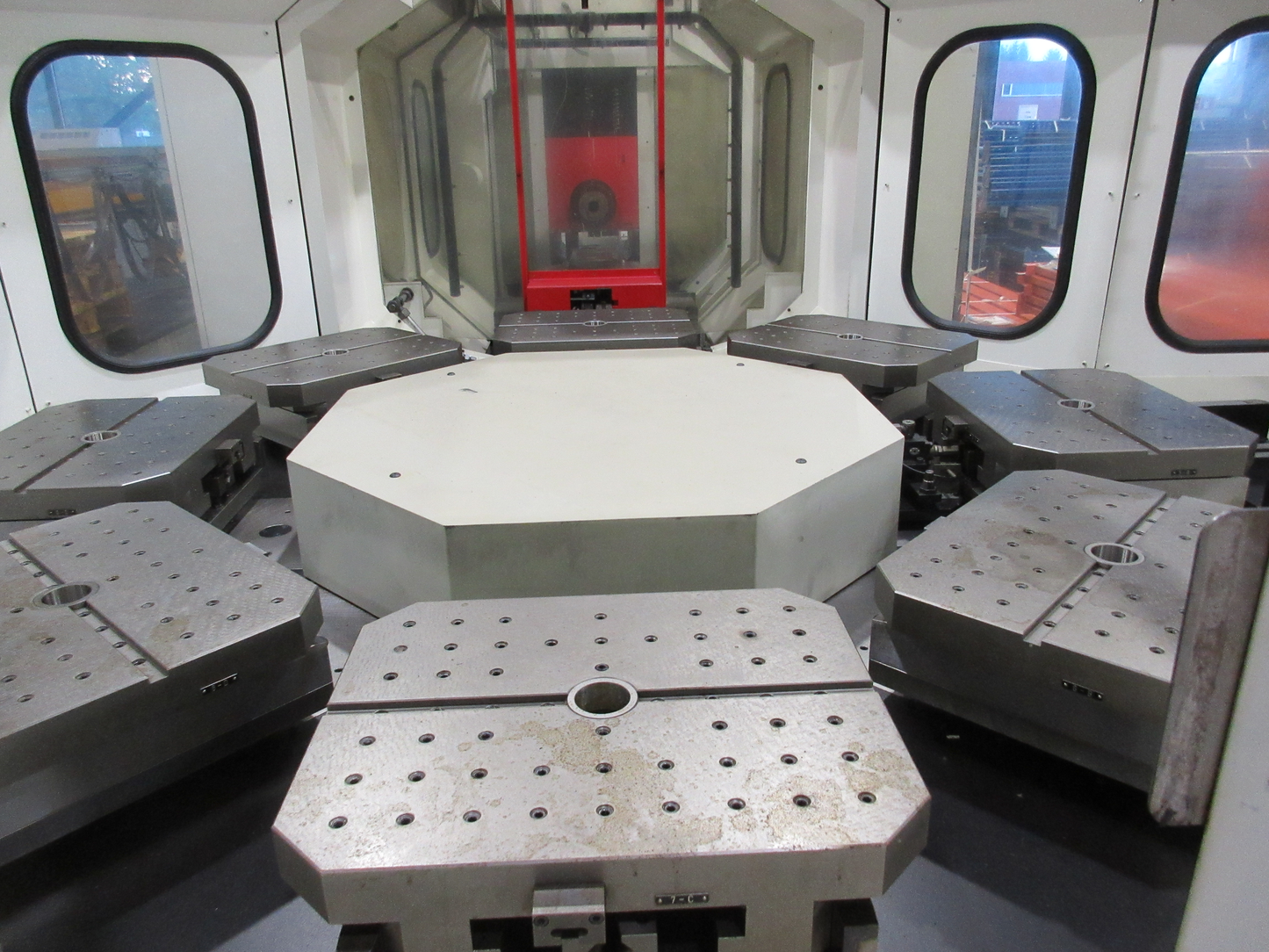

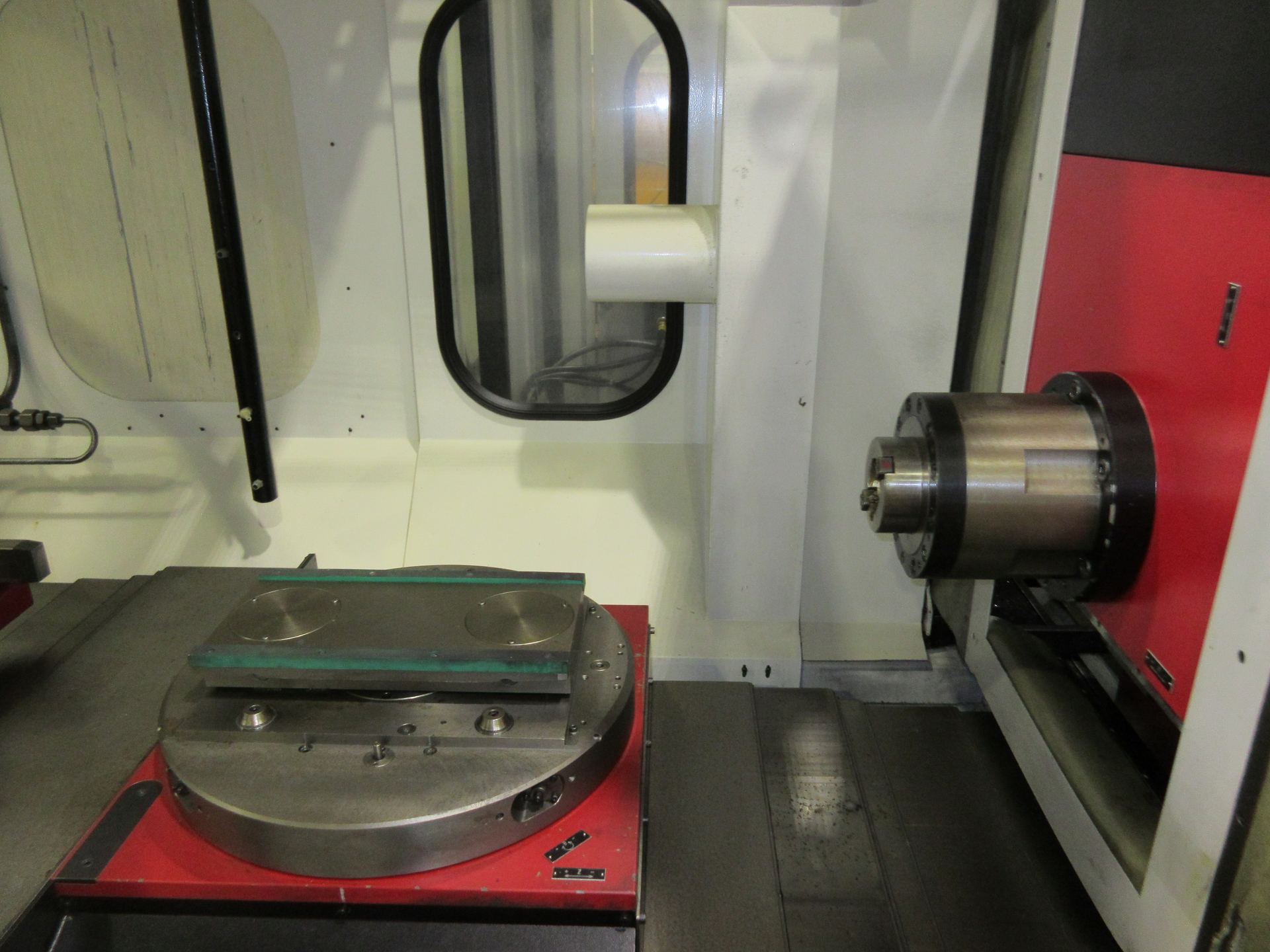

DIXI DPC 150

Type: DPC 150

Manufacturer: DIXI

Group: Machining center

Subgroup: Horizontal machining center

Control: GE FANUC

Stock: 022535

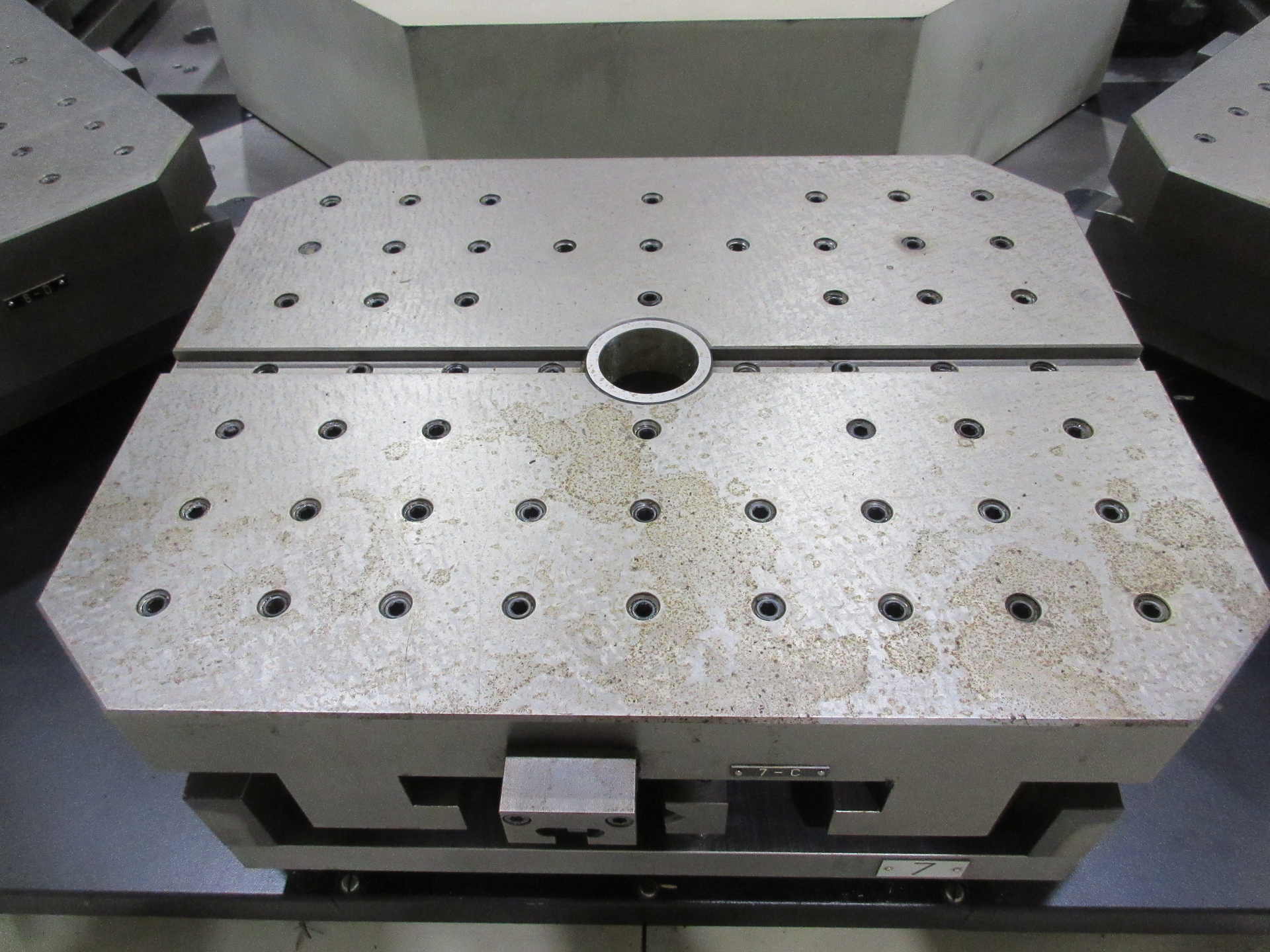

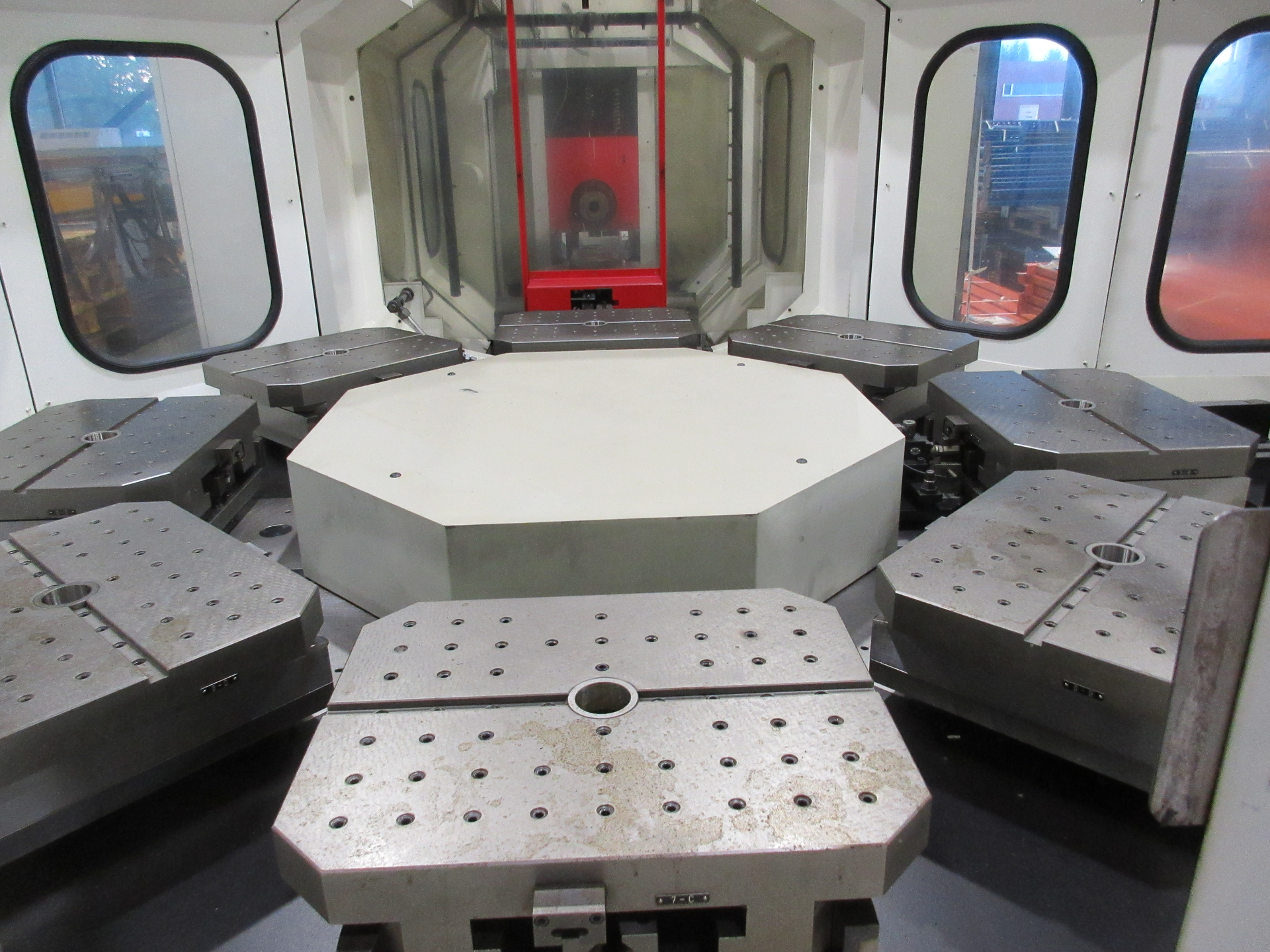

DIXI DPC 150 is a horizontal machining center engineered for precision, high accuracy and reliability. Travels X700 Y500 Z700 mm; table division B 360'000x0.001°. Pallets: 9 (500x400 mm) load 500 kg; tool magazine 144 positions (2x72), max tool weight 12 kg. Spindle ISO40 40–10,000 rpm, 15 kW; feeds 1–10,000 mm/min, rapid 15 m/min. Supply 3x380V 50Hz; total power 55 kW (65 kVA); weight ~11,000 kg; dims 6840x3400x3000 mm. Accessories: full splash cabin, coolant system, coolant through spindle, pallet changer. Suited to tight tolerances in automotive, aerospace, medical, watchmaking and machine-tool sectors.

| Longitudinal travel (X-axis) | 700 mm |

| Transversal travel (y-axis) | 500 mm |

| Vertical travel (z axis) | 700 mm |

| Table divisions (B) | 360'000x0.001 ° |

| Table speeds: | |

| up to | 15 t/min |

| Pallets: | |

| numbers | 9 |

| Length | 500 mm |

| Width | 400 mm |

| Time of changing palets | 14 s |

| Transport weight | 500 kg |

| Tool changer: | |

| Number of tools | 144 (2x72) |

| Max. tool-weight | 12 kg |

| Time of tool changing | 6 - 8 s |

| Spindle nose: ISO | 40 |

| Horizontal spindle speeds: | |

| stepless | |

| from | 40 t/min |

| up to | 10000 t/min |

| Feeds: | |

| stepless | |

| longitudinal from | 1 mm/min |

| up to | 10000 mm/min |

| transversal from | 1 mm/min |

| up to | 10000 mm/min |

| vertical from | 1 mm/min |

| up to | 10000 mm/min |

| Rapid traverse: | 15 m/min |

| Voltage 50 Hz 3x | 380 Volt |

| Spindle motor | 15 kW |

| Total power required | 55 kW |

| Total power required | 65 kVA |

| Machine's weight about | 11000 kg |

| Overall dimensions machine: | |

| Length | 6840 mm |

| Width | 3400 mm |

| Height | 3000 mm |

| Various accessories: | |

| Full splash cabin | |

| Coolant system | |

| Coolant through spindle (cts) | |

| Pallets chanching device: | |

| Pallets: number | 8 |

| Set of toolholders | |

| Set of cutter arbors |

Need Assistance? Just WhatsApp Us!

Need Assistance? Just WhatsApp Us!