1

/

of

7

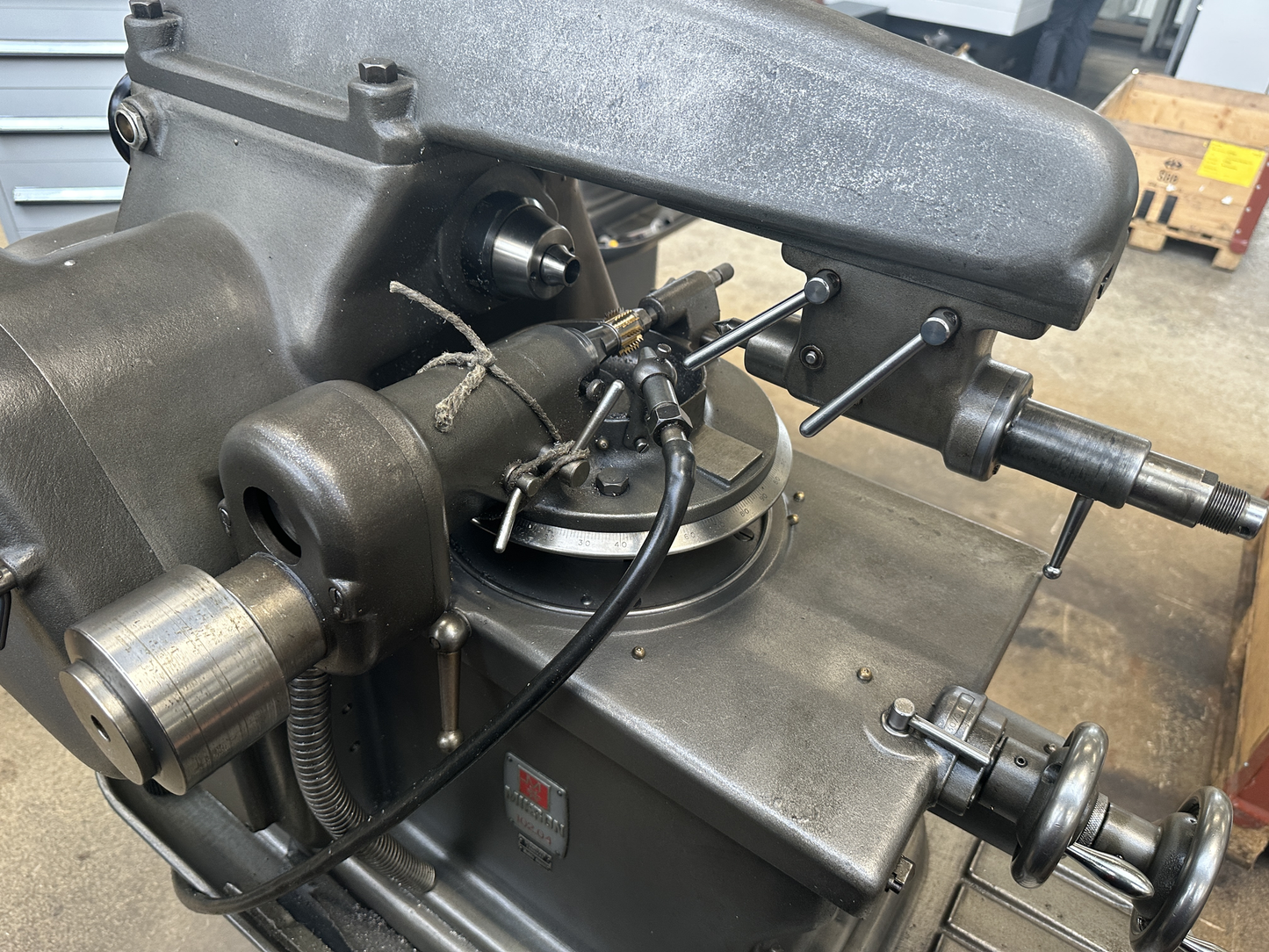

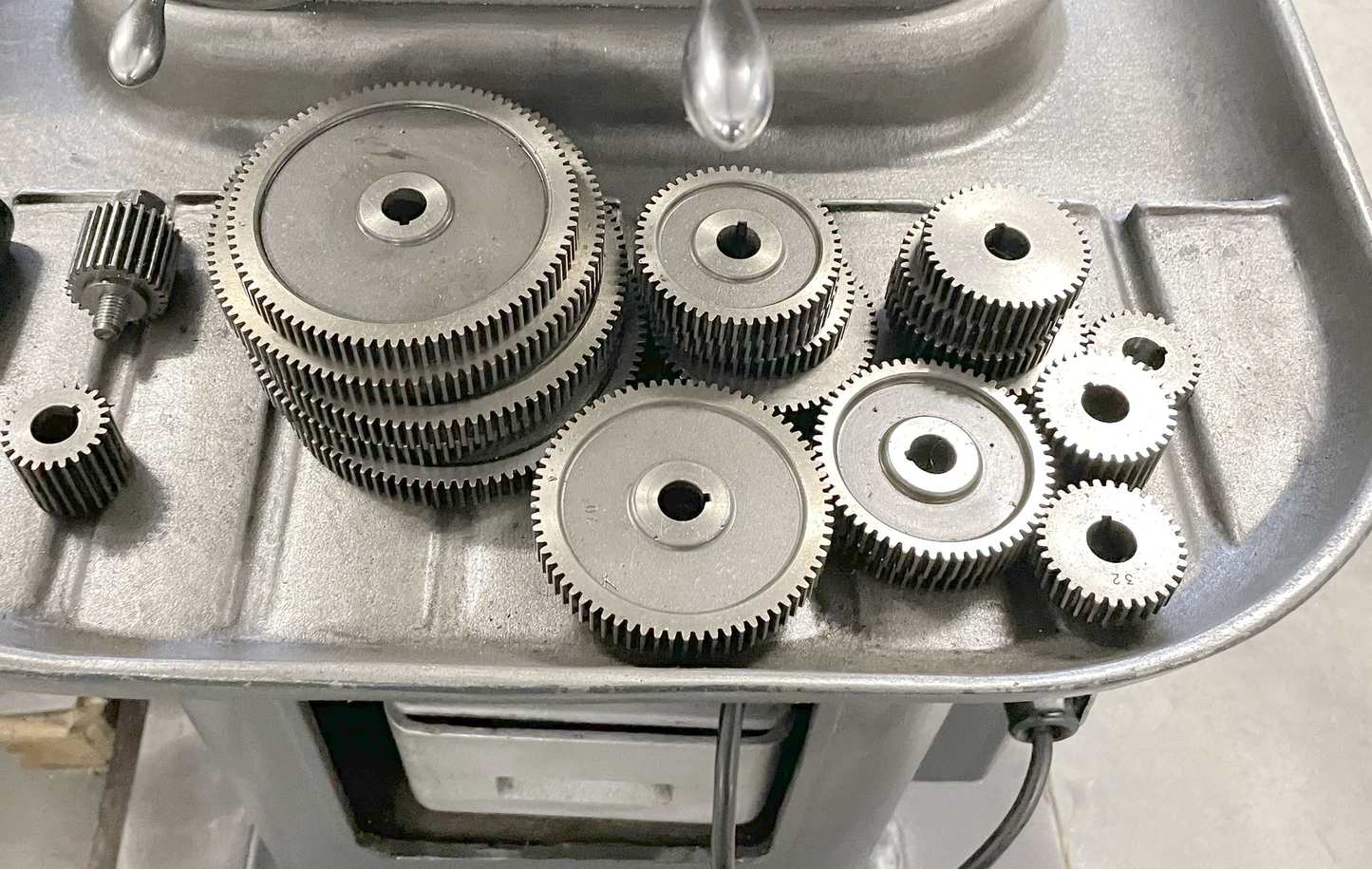

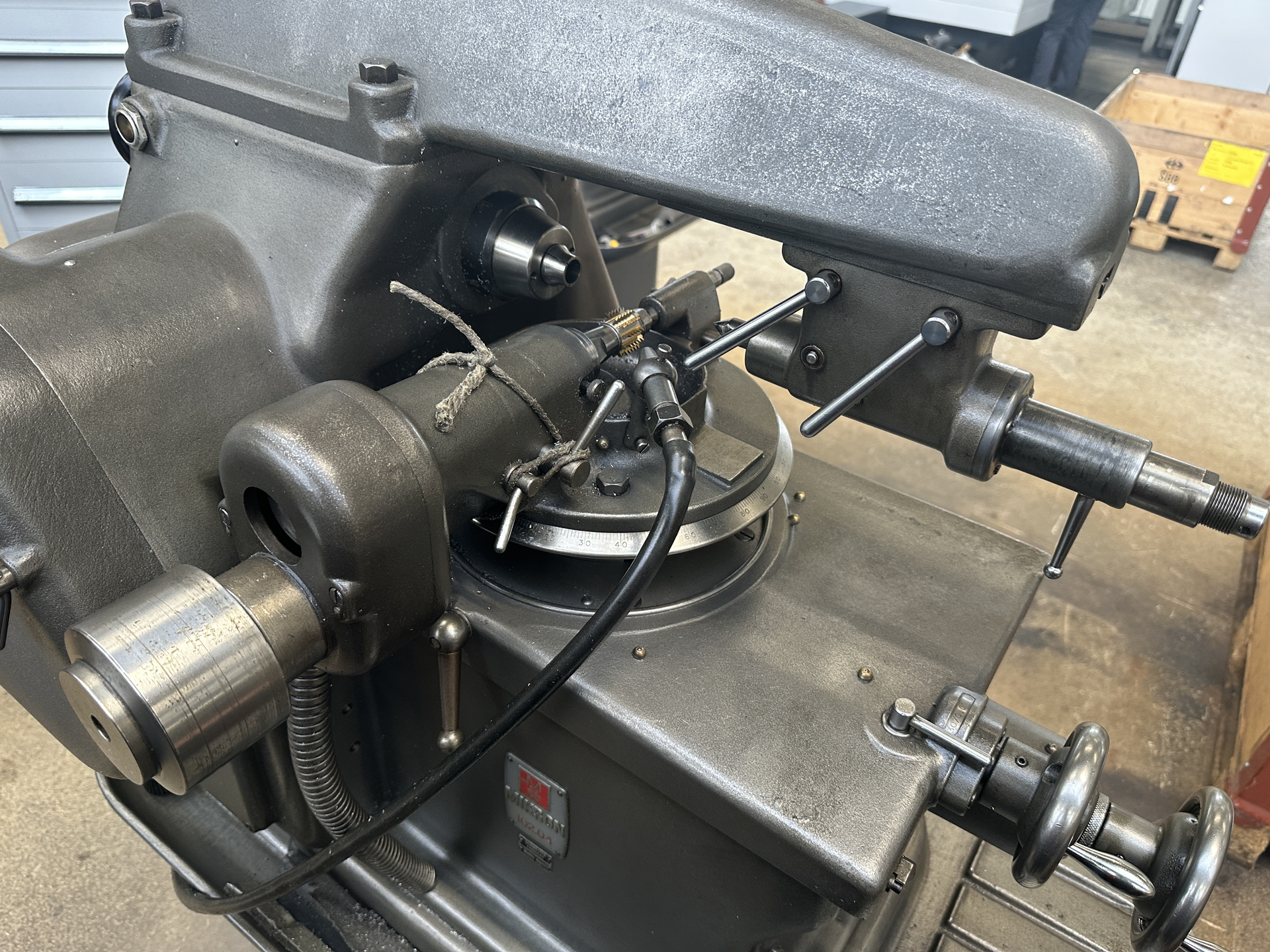

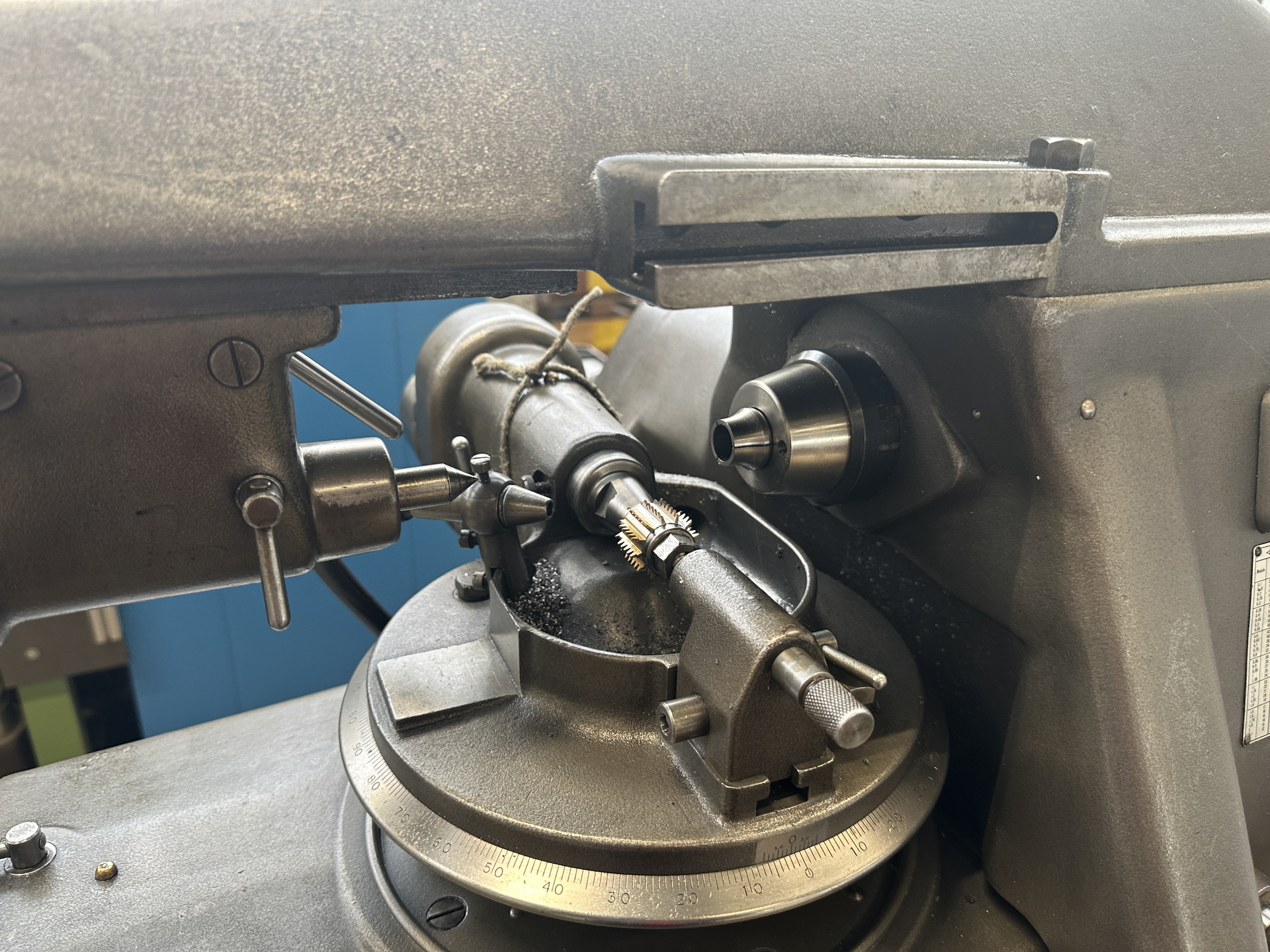

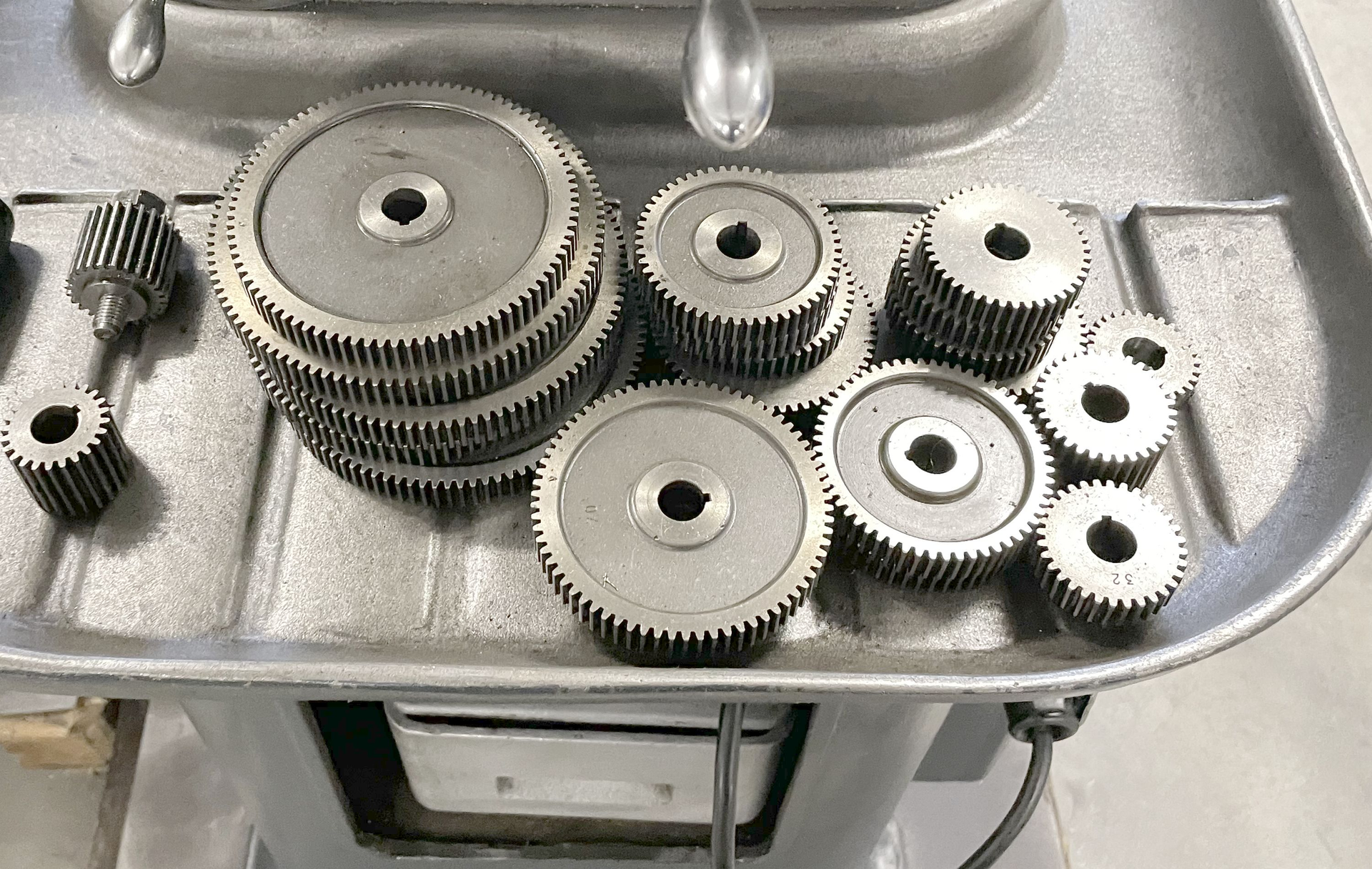

MIKRON 102.04 is a Hobbing machine engineered for precision, high accuracy and reliability. Work capacity: max Ø 120 mm; max module 2; workpiece length 130 mm; teeth 6–325; spiral lead 2–5000 mm; lead angle 1°–89°. Gear hob Ø min 130 mm; cutter speeds 14 steps 140–1870 t/min; axial feeds up to 3 mm/t. Voltage 3×380V 50Hz; power 1.5 CV; weight ~650 kg; dimensions 1100×900×1550 mm. Accessories: set of gears. Achieves tight tolerances; suited to automotive, watchmaking, machine tools, aerospace and medical.

| Work capacity:max. diameter | 120 mm |

| Max. module | 2 |

| Workpiece length max. | 130 mm |

| Pitch min. | 6 |

| max. | 325 |

| Spiral lead: | |

| from | 2 mm |

| up to | 5000 mm |

| Spiral lead angle: | |

| from | 1 ° |

| up to | 89 ° |

| Gear hob: | |

| min. diameter | 130 mm |

| Milling cutter speeds: | |

| number (steps) | 14 |

| from | 140 t/min |

| up to | 1870 t/min |

| Feeds: | |

| axial from | mm/t |

| up to | 3 mm/t |

| Voltage 50 Hz 3x | 380 Volt |

| Power | 1.5 CV |

| Machine's weight about | 650 kg |

| Overall dimensions machine: | |

| Length | 1100 mm |

| Width | 900 mm |

| Height | 1550 mm |

| Various accessories: | |

| Set of gears | |

| Fabrication de filetages: | |

| Tangent gear cutting | |

| Inclined gear cutting | |

| Dentures coniques | |

| Spiral gear cutting | |

| External gear cutting | |

| Internal gear cutting |

Need Assistance? Just WhatsApp Us!

Need Assistance? Just WhatsApp Us!