1

/

of

21

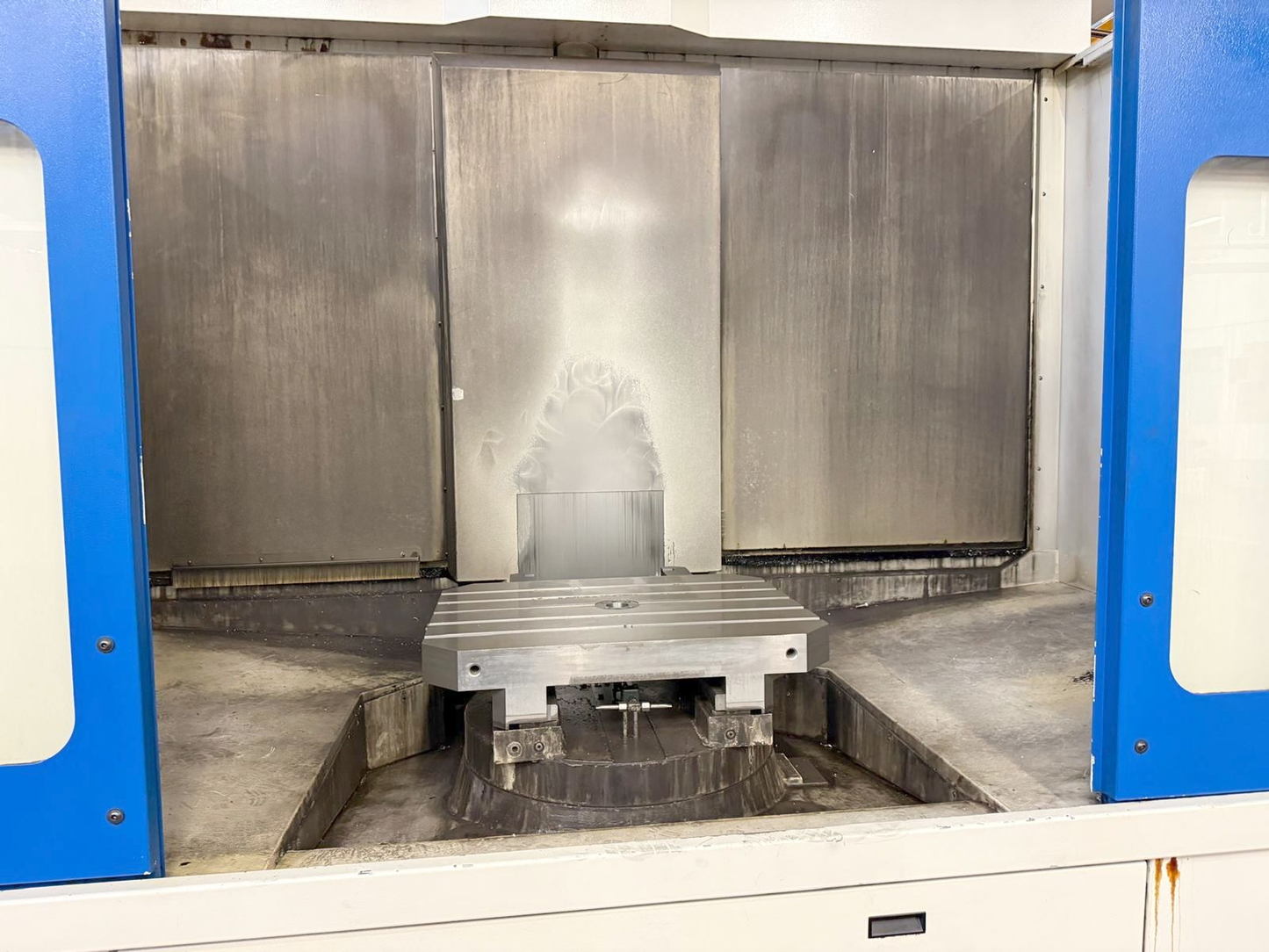

HÜLLER HILLE NBH 230

Type: NBH 230

Manufacturer: HÜLLER HILLE

Group: Machining center

Subgroup: Horizontal machining center

Control: SIEMENS SINUMERIK 840 D

Year: 2003

Stock: 021836

HÜLLER HILLE NBH 230 is a Horizontal machining center for precision, high accuracy and reliability. Travels X/Y/Z 1200/1000/1200 mm; max swing 1200 mm. 2 tables; pallets 800×630 mm, 1,200 kg, change 16 s. TC 250 pos.; max Ø tool 125 mm (250 mm free), L 650 mm, change 2.5–4.5 s. Spindle SK50 25–6000 rpm, torque 900/1130 Nm; feed 1–36000 mm/min, rapid 36 m/min. Coolant 1250 l, booster 11 bar, thru‑spindle 25/50 bar; chip conveyor, glass scales, probe. Spindle refurbished 2015. Suitable for automotive, aerospace, medical, toolmaking.

| Number of tables | 2 |

| Maximum swing circle of up to | 1200 mm |

| Longitudinal travel (X-axis) | 1200 mm |

| Transversal travel (y-axis) | 1000 mm |

| Vertical travel (z axis) | 1200 mm |

| Table speed | 15 t/min |

| Holding torque of the table | 10000 Nm |

| Tilting moment | 29000 Nm |

| Pallets: | |

| Length | 800 mm |

| Width | 630 mm |

| Time of changing palets | 16 s |

| Transport weight | 1200 kg |

| Tool changer: | |

| Number of tools | 250 |

| Tool diameter max. | 125 mm |

| Diameter with free adjacent pockets | 250 mm |

| Tool lenght | 650 mm |

| Max. tool-weight | 40 kg |

| Time of tool changing | 2.5 - 4.5 s |

| Average chip-to-chip time | 7 - 9 s |

| Spindle nose SK | 50 DIN69871 |

| Distance spindle nose to table | 130 mm |

| Spindle speeds: | |

| stepless | |

| from | 25 t/min |

| up to | 6000 t/min |

| Torque max. | 900 / 1130 Nm |

| Feed range | 1 - 36000 mm/min |

| Rapid traverse: | 36 m/min |

| Machine's weight about | 30000 kg |

| Overall dimensions machine: | |

| Length | 10000 mm |

| Width | 6000 mm |

| Height | 3800 mm |

| Various accessories: | |

| Direct measurement by glass scales | |

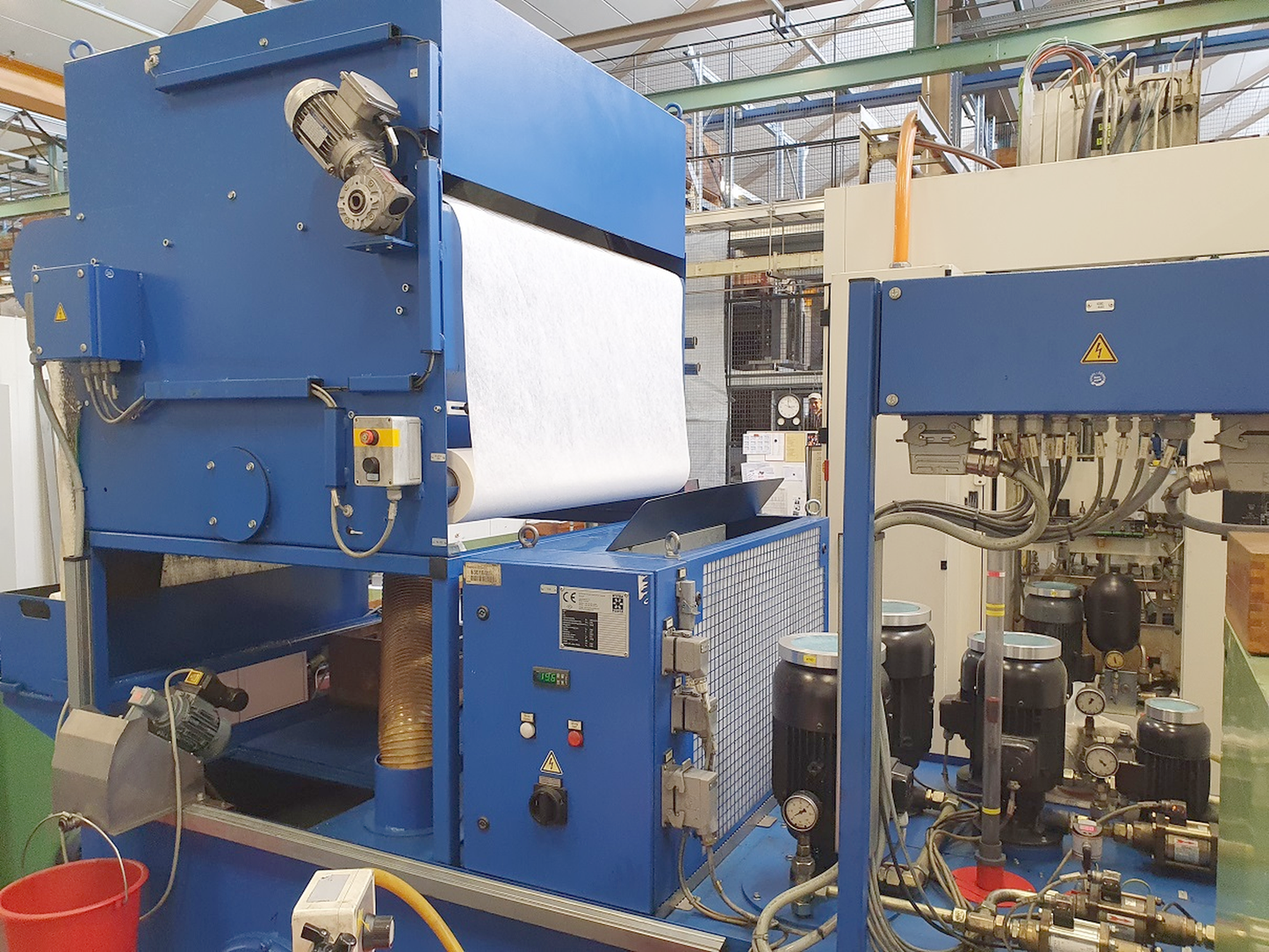

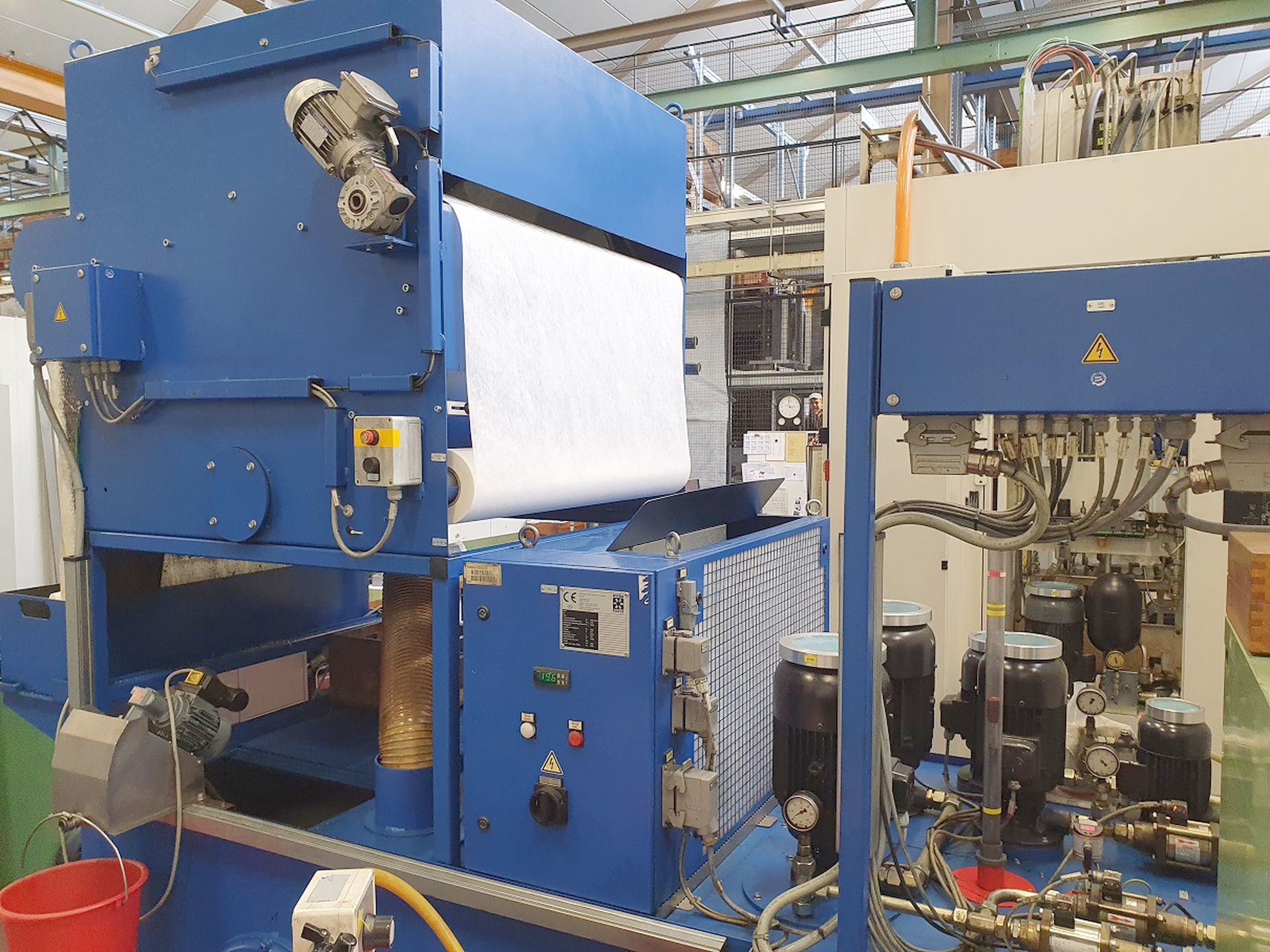

| Coolant system | 1250 l |

| Booster pump (coolant) | 11 bar |

| Coolant through spindle (cts) | 25 / 50 bar |

| Spindle blow out device | |

| Paper filtration system | |

| Chip conveyor | |

| Pallets chanching device: | |

| Pallets: number | 2 |

| Set of toolholders | |

| Oil mist extractor | |

| Measuring feeler gauge | |

| Notes: | |

| Spindle refurbished | 2015 |

Need Assistance? Just WhatsApp Us!

Need Assistance? Just WhatsApp Us!