1

/

of

10

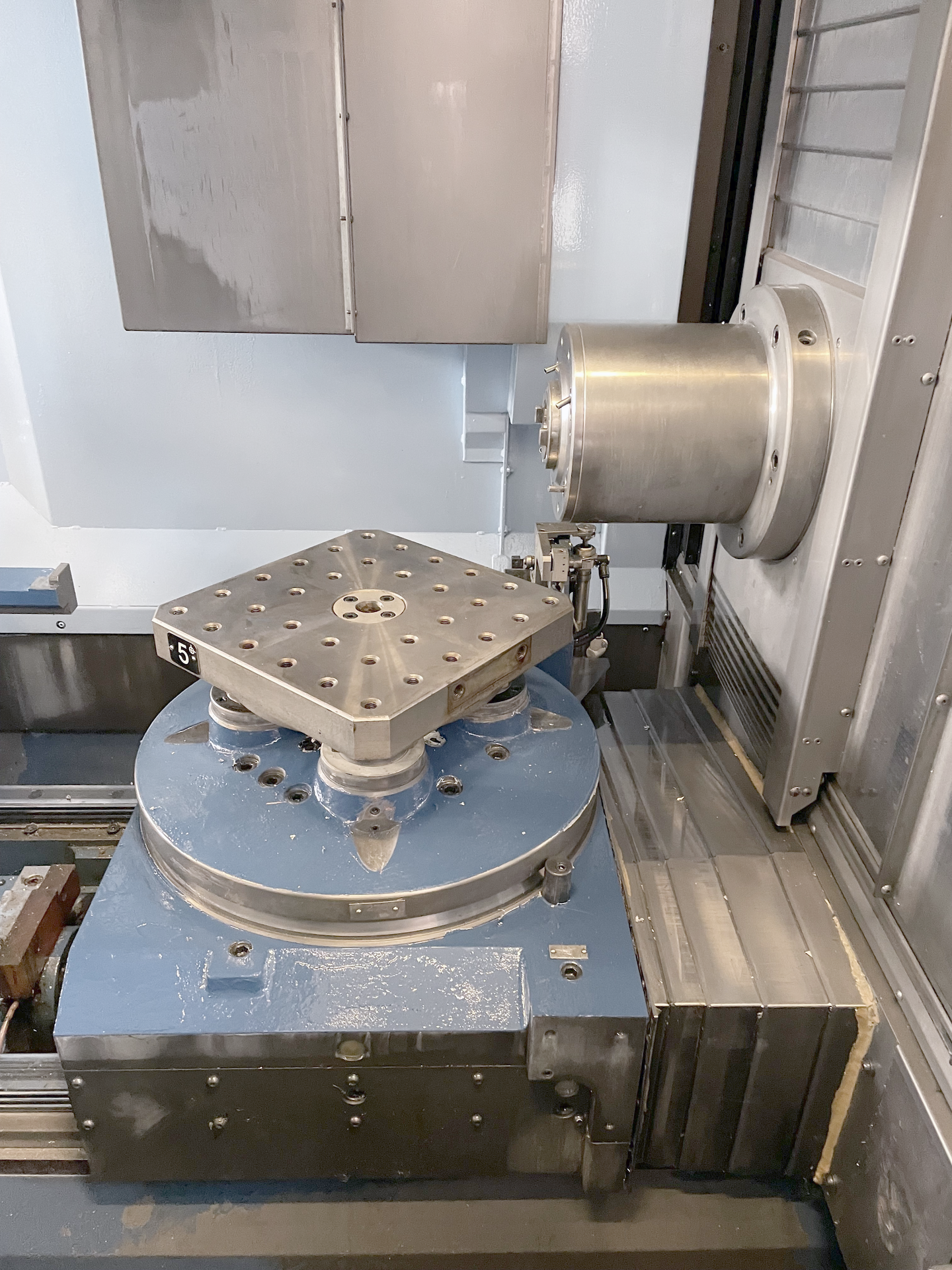

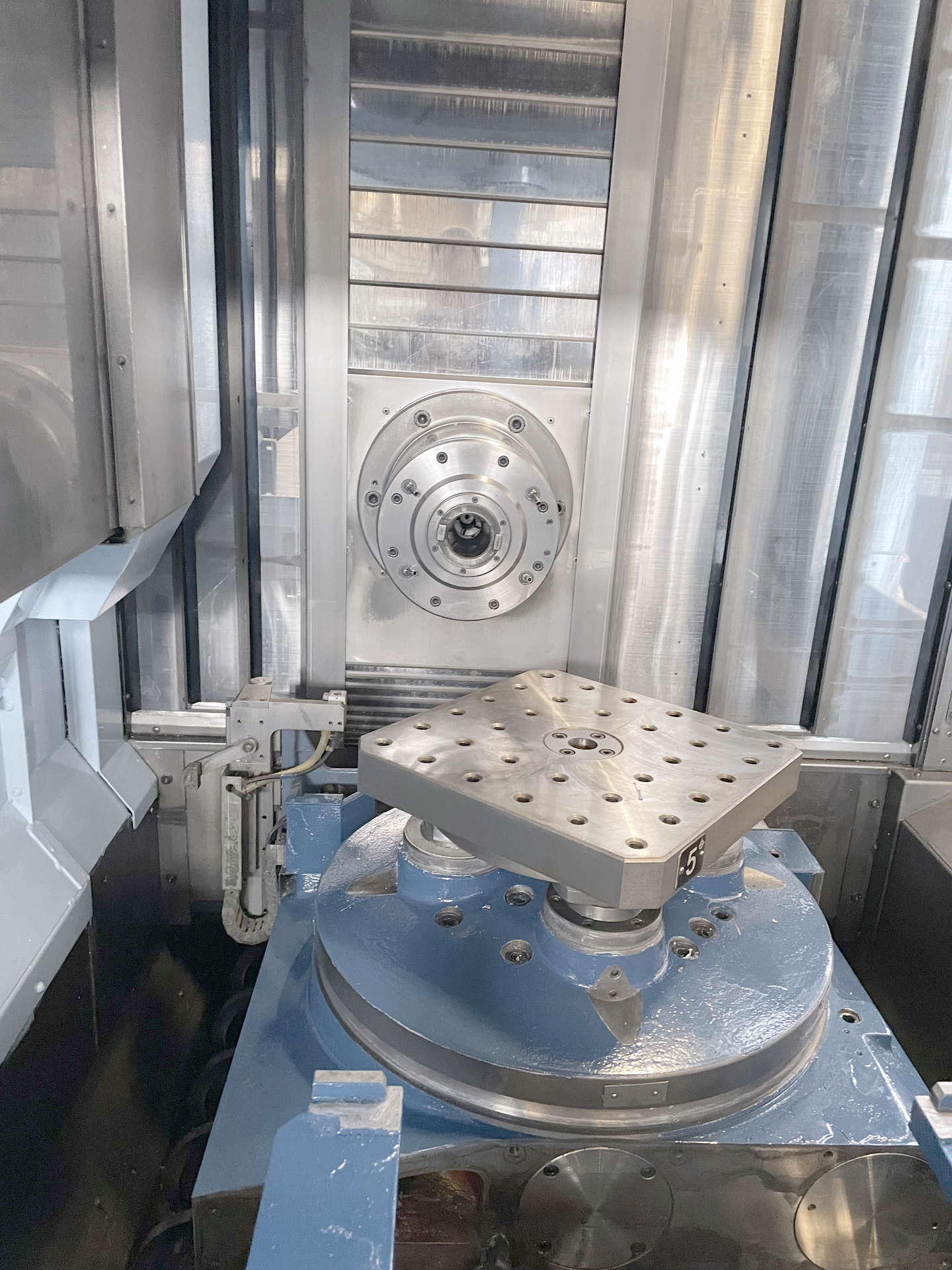

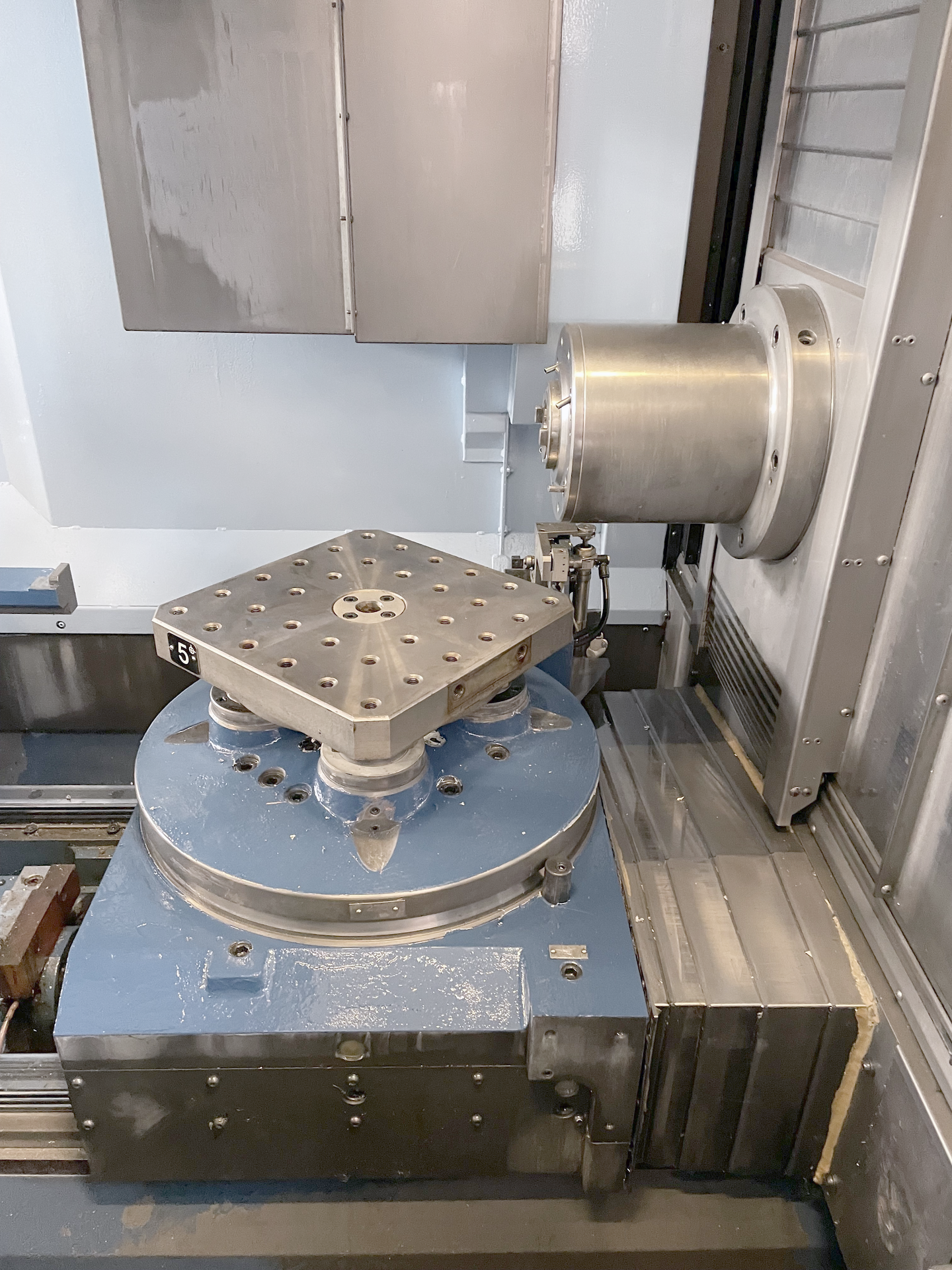

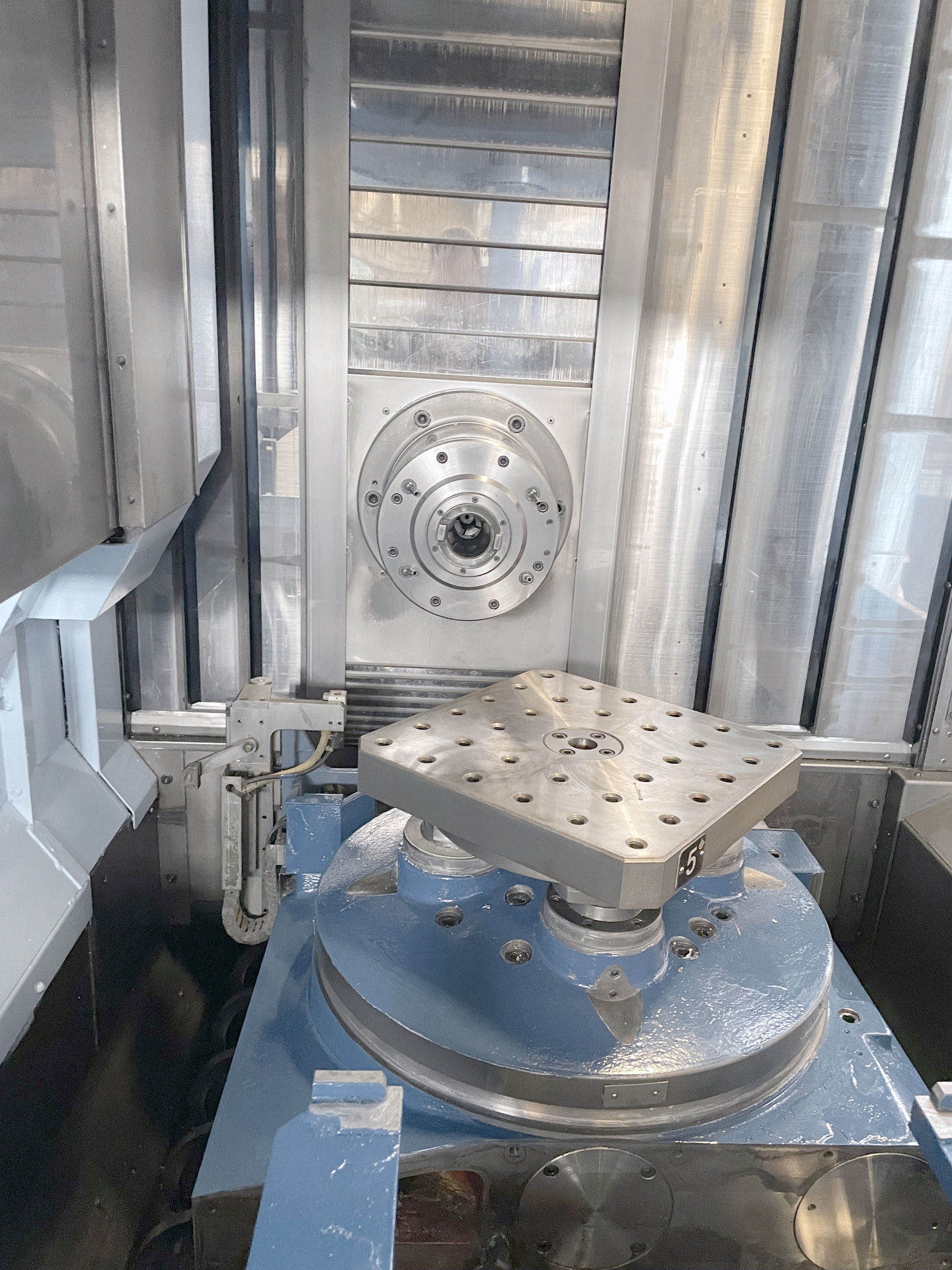

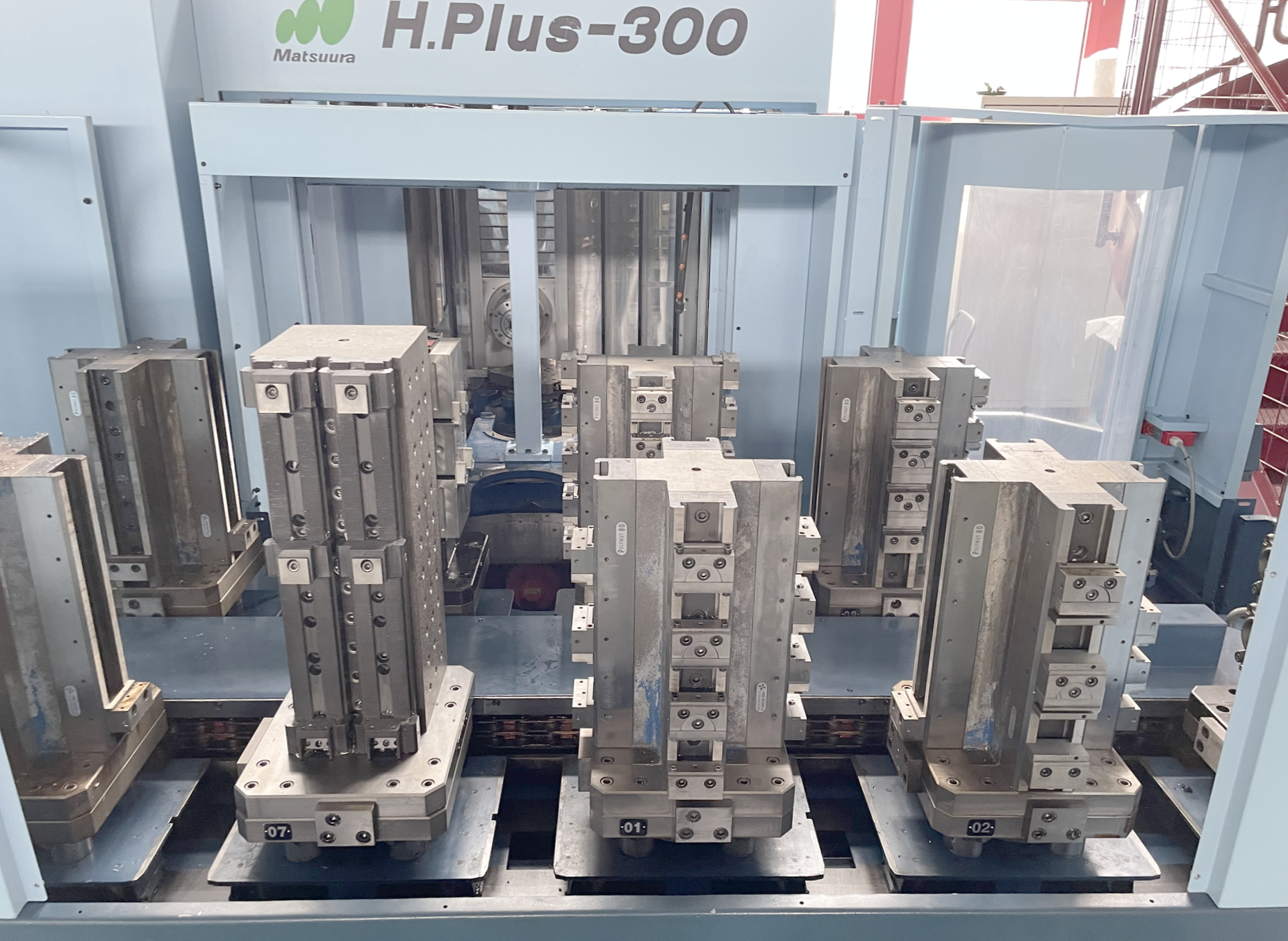

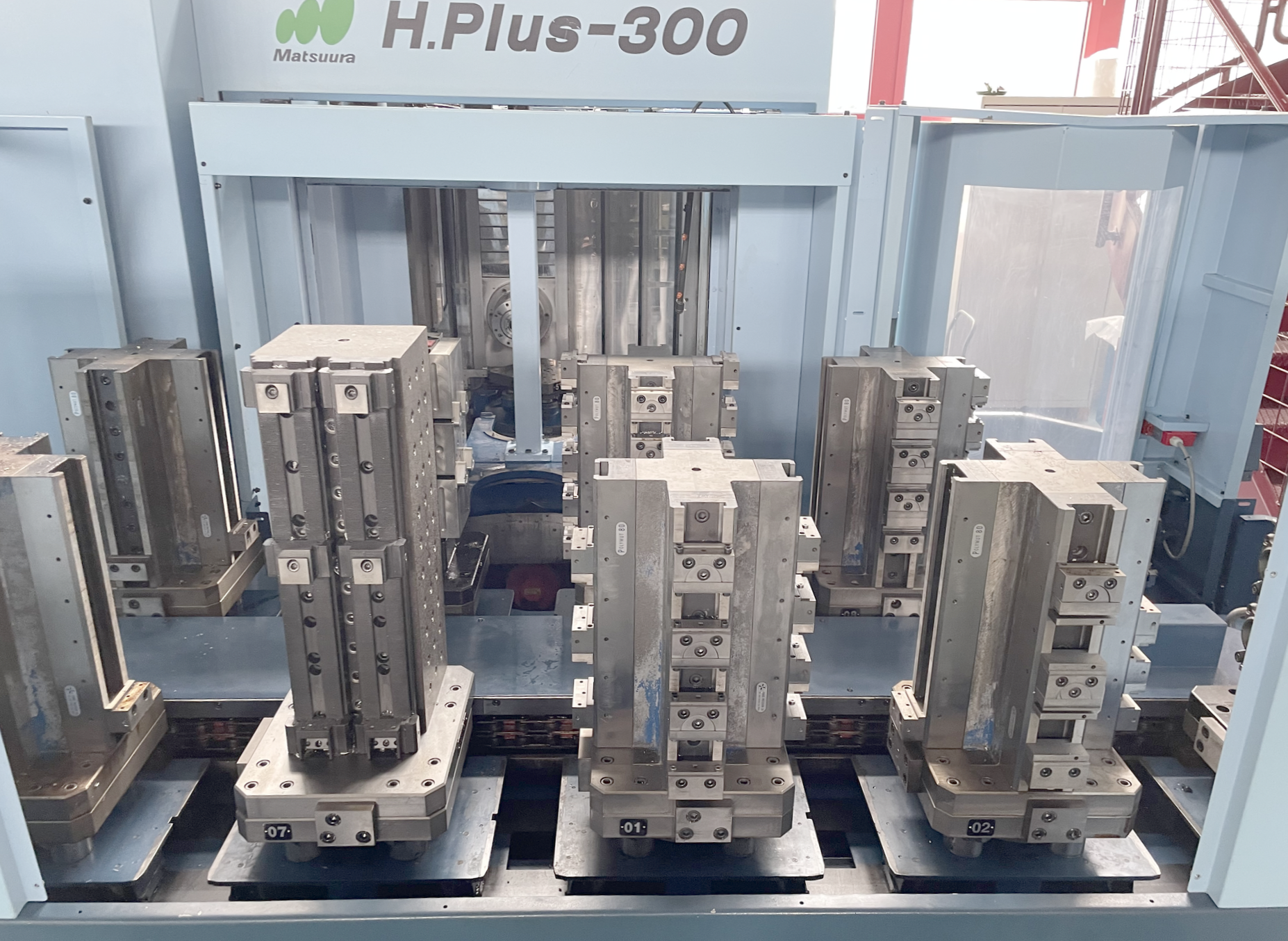

MATSUURA H. PLUS 300

Type: H. PLUS 300

Manufacturer: MATSUURA

Group: Machining center

Subgroup: Horizontal machining center

Control: Matsuura G-Tech 30i

Year: 2006

Stock: 021765

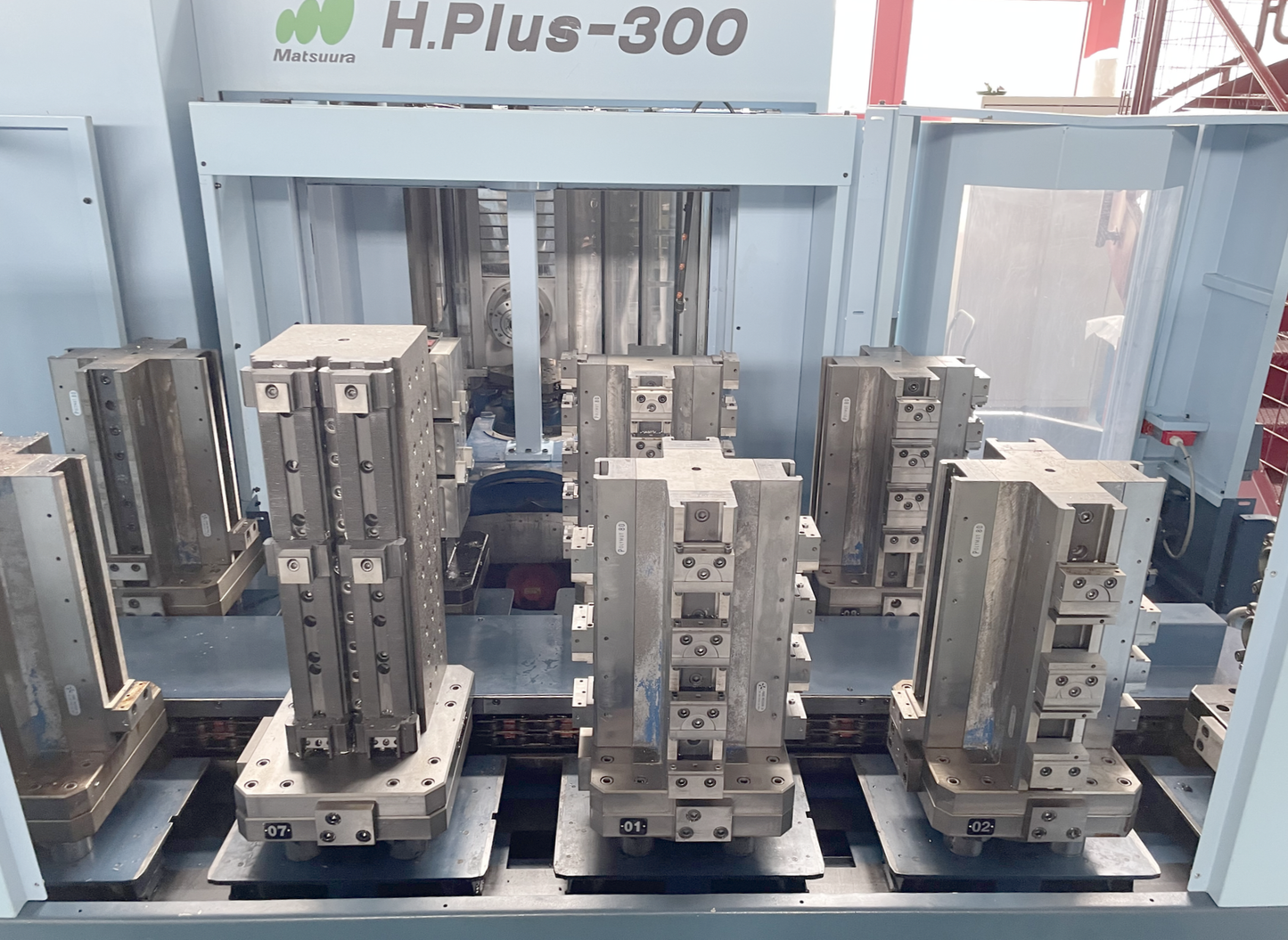

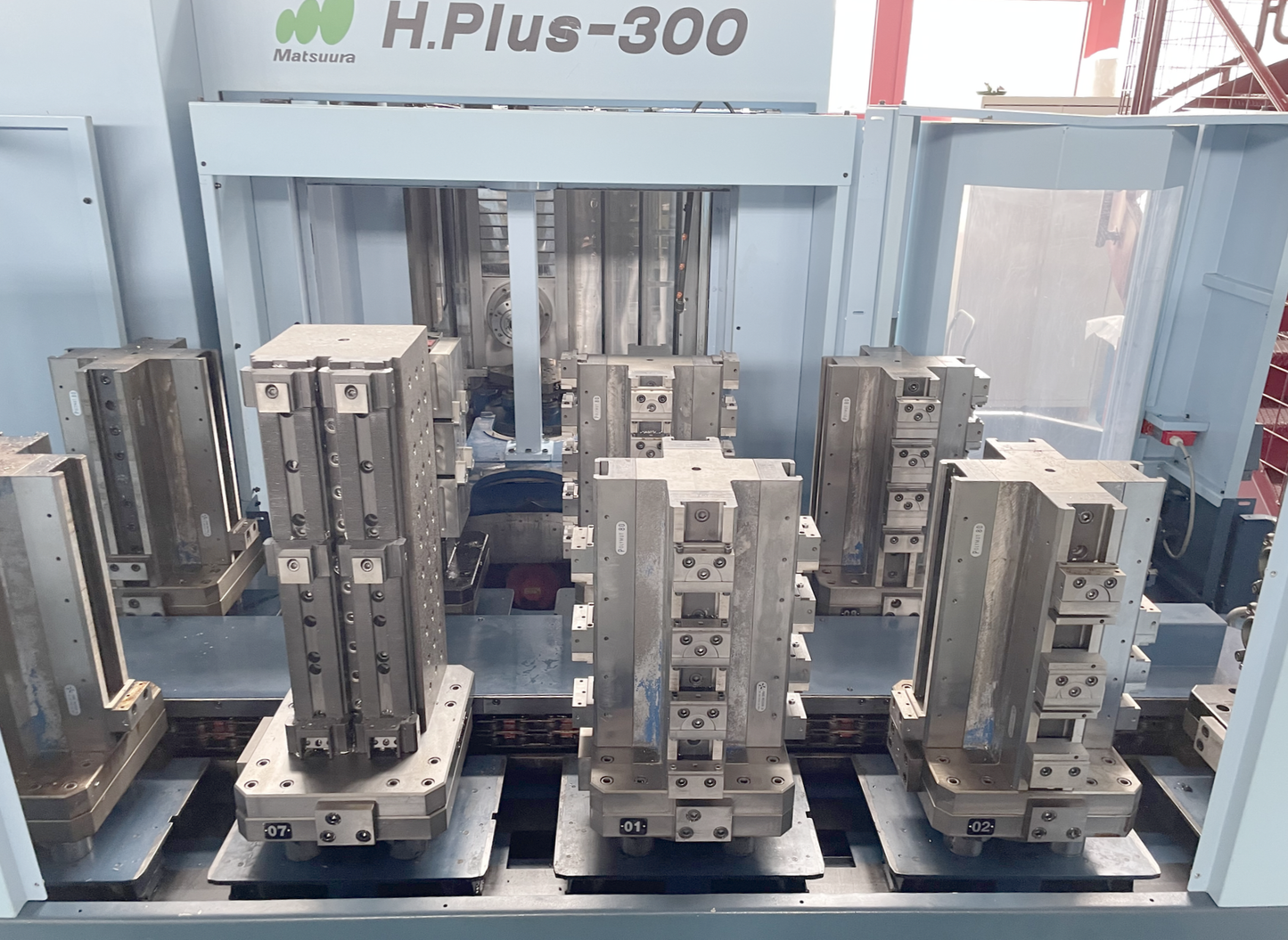

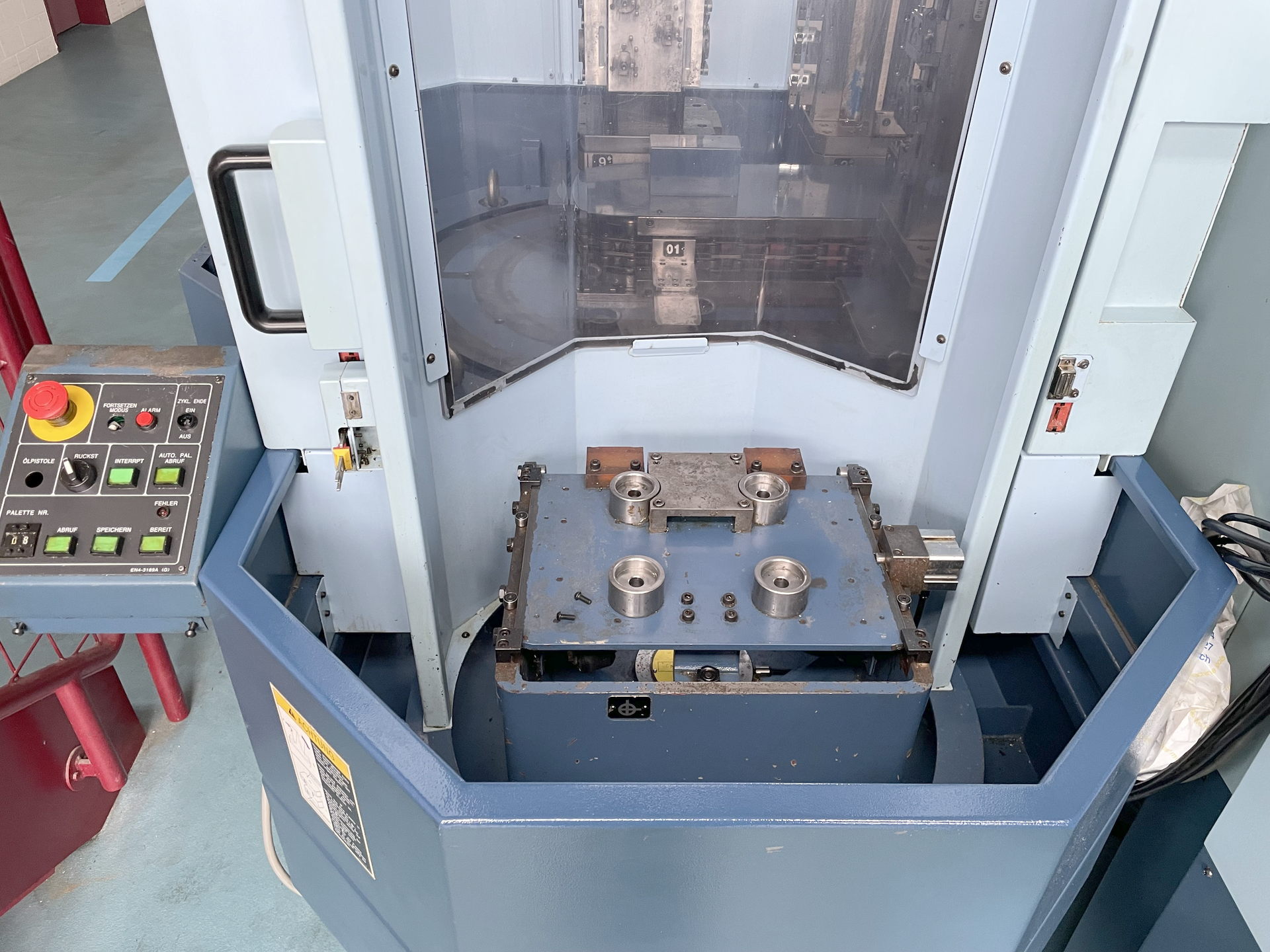

MATSUURA H. PLUS 300 is a Horizontal machining center with high precision, excellent accuracy and reliability. Travels X/Y/Z 500 mm; workpieces Ø 530 mm, h 700 mm; pallets 300×300 mm (10), max workpiece 250 kg, change 7 s. Spindle BT40 50–15,000 rpm, 95.4 Nm, 15/22 kW; feeds 1–50,000 mm/min, rapid 50 m/min; 3×380 V 50 Hz; weight ≈7000 kg; dims 3660×2463×2445 mm. Tool magazine 90 pos., tool change 2 s, chip-to-chip 2.9 s. Coolant 1500 l, chip conveyor, toolholder set, spindle oil cooler. Suited to tight tolerances in automotive, aerospace, medical, watchmaking and mould/die.

| Number of axis total | 4 |

| Number of spindles | 1 |

| Longitudinal travel (X-axis) | 500 mm |

| Transversal travel (y-axis) | 500 mm |

| Vertical travel (z axis) | 500 mm |

| Dimension of the workpice: | |

| Height | 700 mm |

| Diameter | 530 mm |

| B axis | 1 ° |

| C axis | 1 ° |

| Pallets chanching device: | |

| numbers | 2 |

| Length | 300 mm |

| Width | 300 mm |

| Maximum workpiece weight | 250 kg |

| Pallet weight | 40 kg |

| Time of changing palets | 7 s |

| Tool changer: | |

| Number of tools | 90 |

| Tool diameter max. | 80 mm |

| Diameter with free adjacent pockets | 150 mm |

| Tool lenght | 300 mm |

| Max. tool-weight | 8 kg |

| Time of tool changing | 2 s |

| Average chip-to-chip time | 2.9 s |

| Spindle nose: BT | 40 |

| Distance spindle nose to table | 80 - 580 mm |

| Spindle speeds: | |

| stepless | |

| from | 50 t/min |

| up to | 15000 t/min |

| Torque max. | 95.4 Nm |

| Feed range | 1 - 50000 mm/min |

| Rapid traverse: | 50 m/min |

| Voltage 50 Hz 3x | 380 Volt |

| Spindle power | 15 / 22 kW |

| Total power required | 44 kVA |

| Machine's weight about | 7000 kg |

| Overall dimensions machine: | |

| Length | 3660 mm |

| Width | 2463 mm |

| Height | 2445 mm |

| Various accessories: | |

| Set of toolholders | |

| Coolant system | 1500 l |

| High pression colant device | |

| Chip conveyor | |

| Pallets chanching device: | |

| Pallets: number | 10 |

| Spindle oil cooler | |

| Rotating viewing window |

Need Assistance? Just WhatsApp Us!

Need Assistance? Just WhatsApp Us!