1

/

of

14

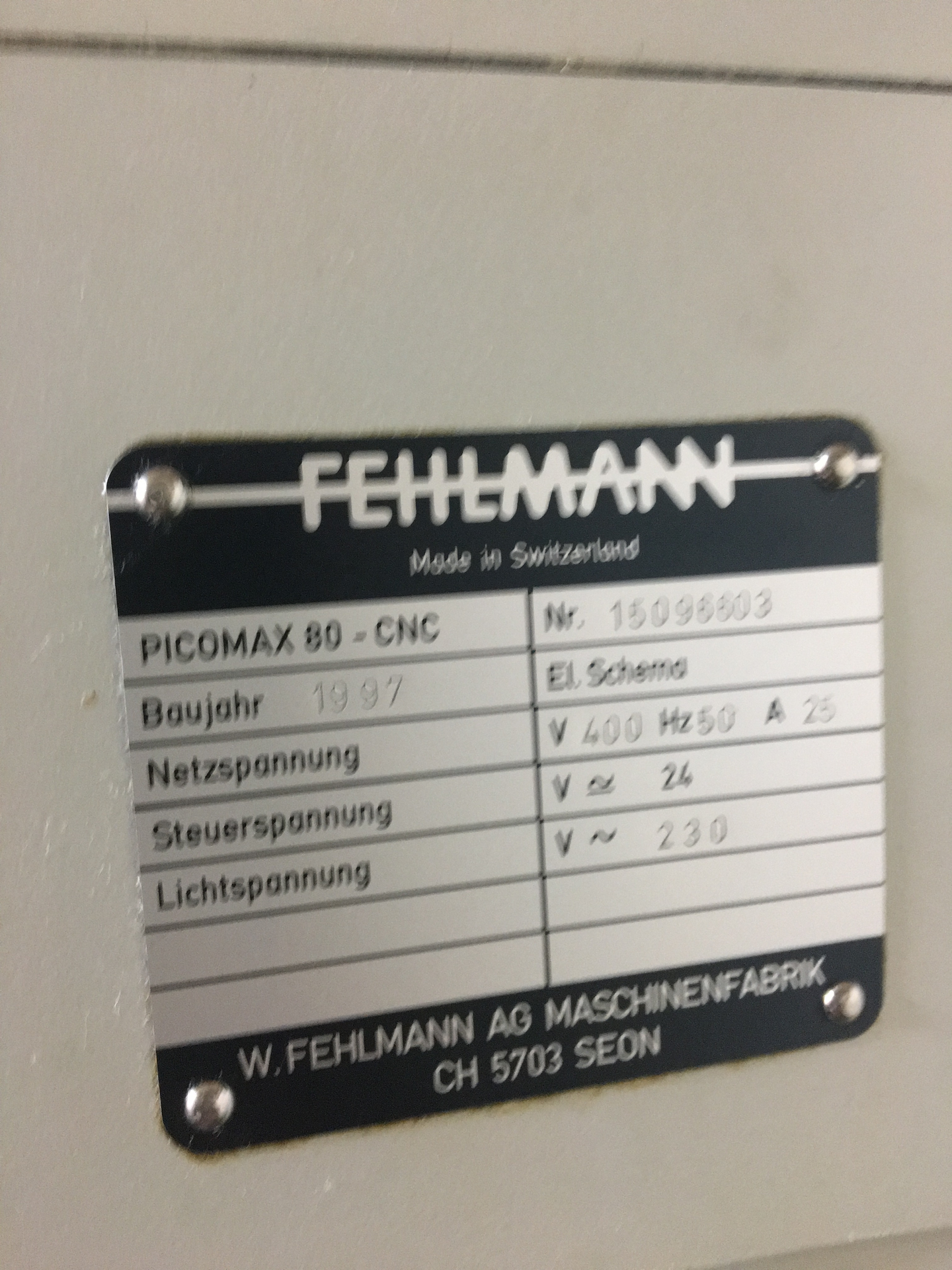

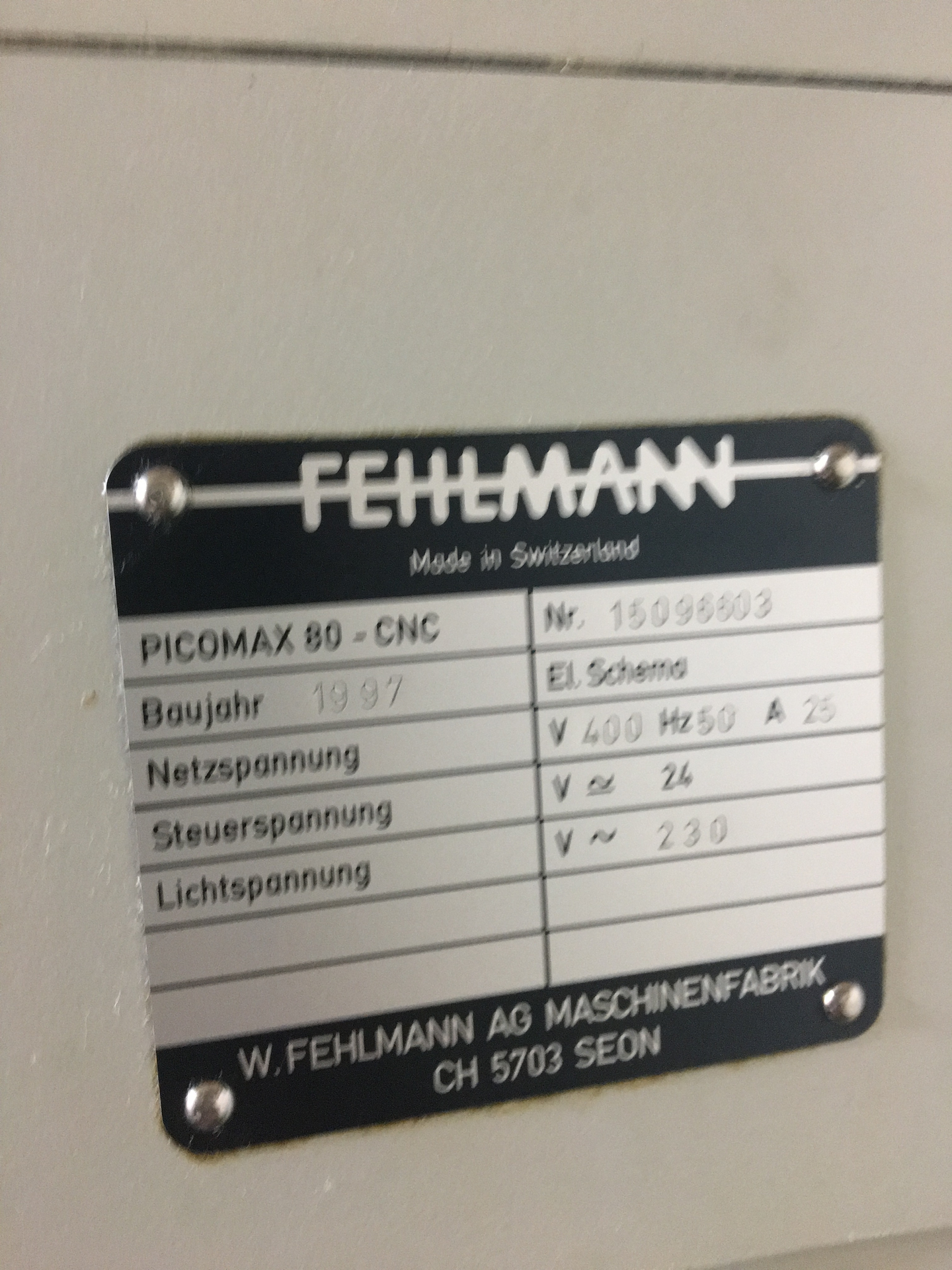

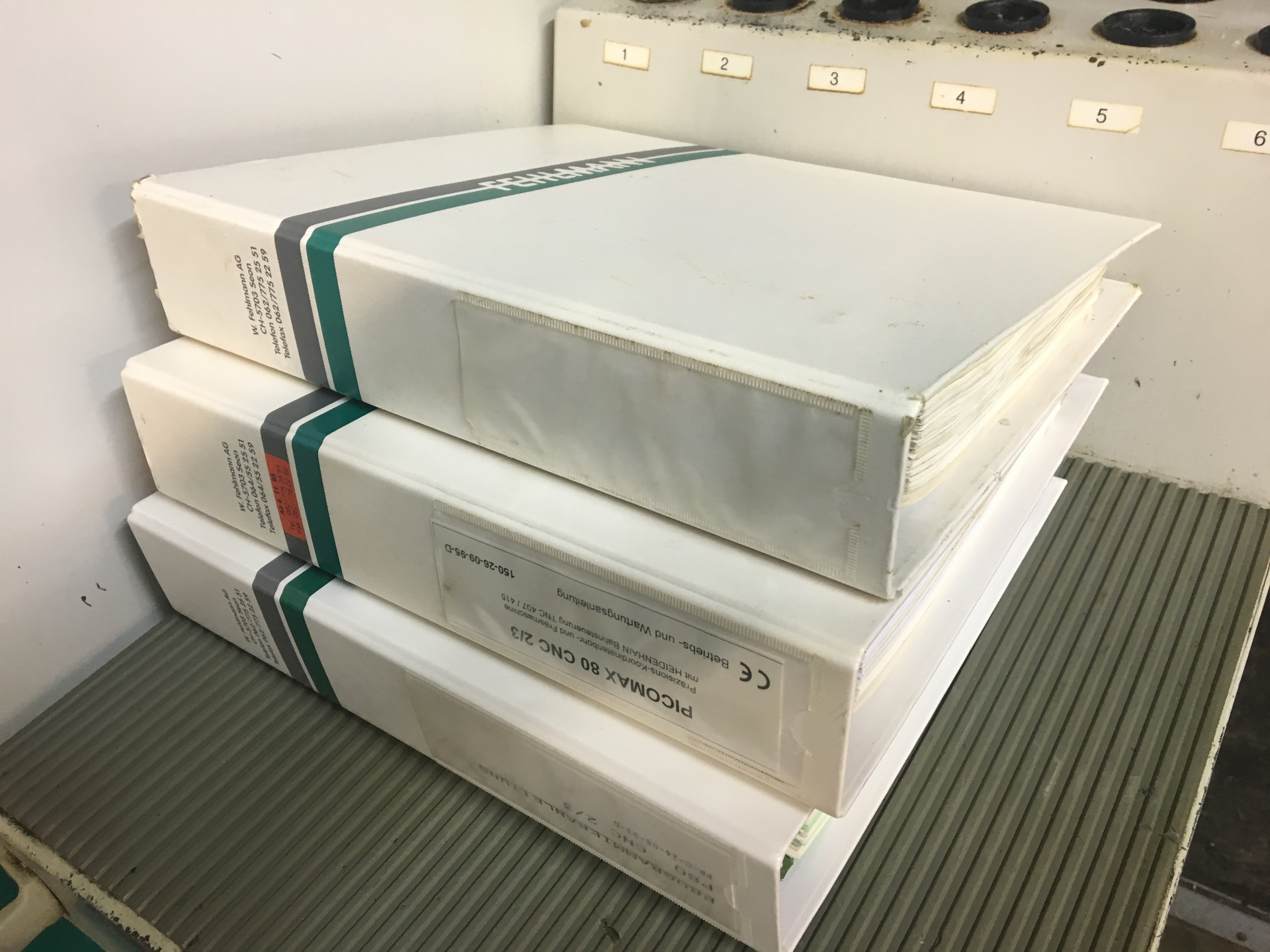

FEHLMANN PICOMAX 80 CNC 2/3

Type: PICOMAX 80 CNC 2/3

Manufacturer: FEHLMANN

Group: CNC drilling machine

Subgroup: CNC milling machine

Control: HEIDENHAIN TNC 407/415

Stock: 019656

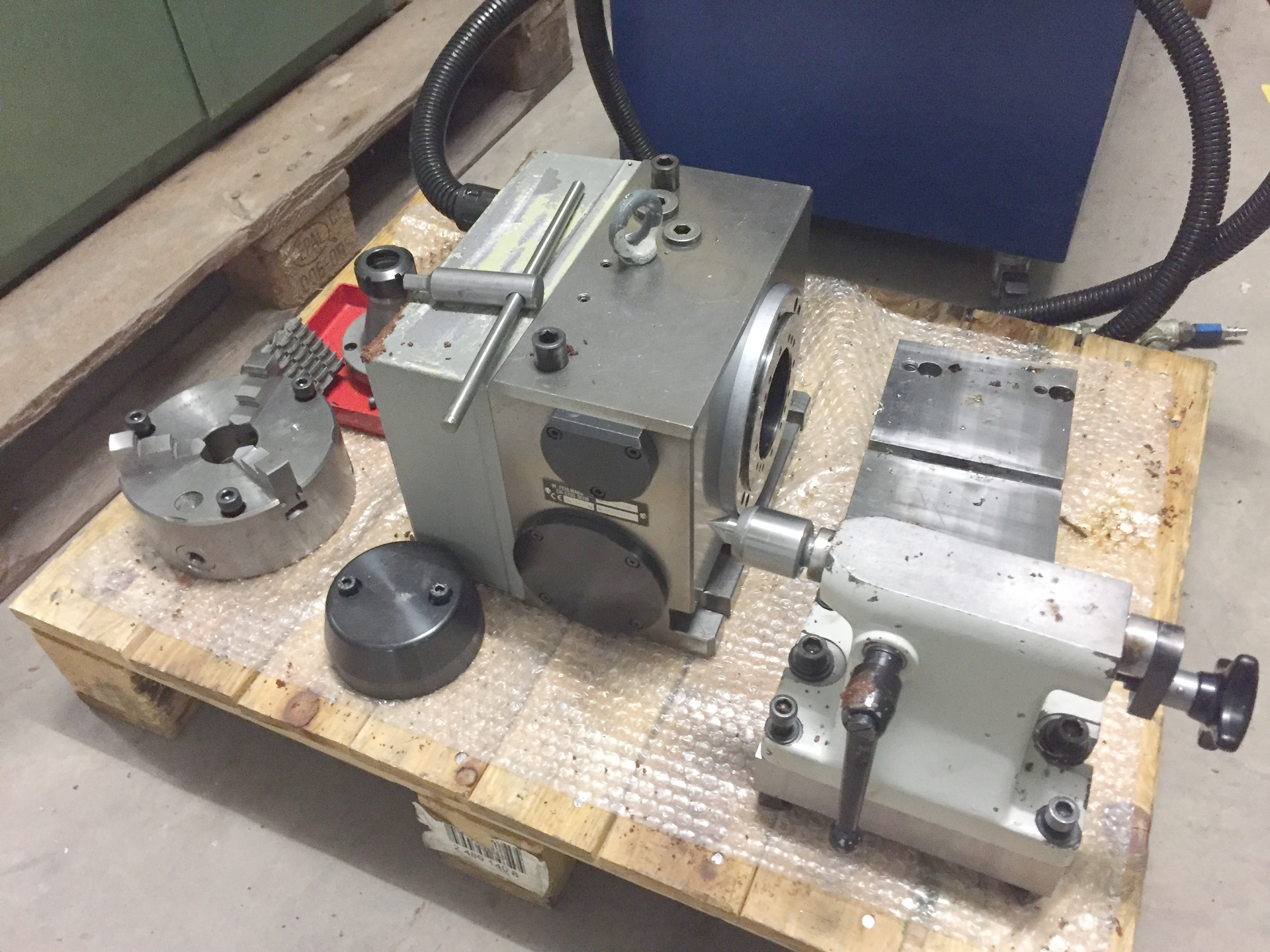

FEHLMANN PICOMAX 80 CNC 2/3 is a CNC milling machine built for precision, high accuracy and reliability. 5 axes; spindle SF32; drill 30 mm; tap M24; milling 100 cm3/min. Table 1230×410 mm, 7 T‑slots 12H8, table load 250 kg, throat 370 mm. Travels X700 Y315 Z170/180 W495 mm; spindle 50–9200 t/min; feeds X/Y 1–9000 Z1–4000 W1–4500 mm/min; rapids X/Y 9 m/min Z4 m/min. Power 3×380V 50Hz, 16 kW; weight ≈3200 kg; dims 2500×2500×2450 mm. Accessories: 4th axis dividing attachment, tailstock, 3‑jaw chuck Ø160 mm, collet device, toolholder set, electronic handwheel. Suited to tight tolerances in watchmaking, medical, aerospace, automotive and machine‑tool production.

| Number of axis total | 5 |

| Spindle nose: | SF 32 |

| Drill capacity in steel | 30 mm |

| Threat cutting in steel M | 24 |

| Milling capacity | 100 cm3/min |

| Spindle speeds: | |

| from | 50 t/min |

| up to | 9200 t/min |

| Table length | 1230 mm |

| Table width | 410 mm |

| Number of T-channels | 7 |

| T-channel width | 12H8 mm |

| Distance of the T-slots | 50 mm |

| Table load max. | 250 kg |

| Height of table above floor | 1010 mm |

| Min. distance from table to spindle | 0 mm |

| Max. distance from table to spindle | 620 mm |

| Depth of throat | 370 mm |

| Travels: | |

| X axis | 700 mm |

| Y axis | 315 mm |

| Spindle stroke (controlled) | 170 mm |

| Z axis (Spindle stroke manual) | 180 mm |

| W-axis (machine head travel) | 495 mm |

| Feeds: | |

| X axis | 1 - 9000 mm/min |

| Y axis | 1 - 9000 mm/min |

| Z axis | 1 - 4000 mm/min |

| W axis | 1 - 4500 mm/min |

| Rapid traverse X | 9 m/min |

| Rapid traverse Y | 9 m/min |

| Rapid traverse Z | 4 m/min |

| Voltage 50 Hz 3x | 380 Volt |

| Power | 16 kW |

| Machine's weight about | 3200 kg |

| Overall dimensions machine: | |

| Length | 2500 mm |

| Width | 2500 mm |

| Height | 2450 mm |

| Various accessories: | |

| Dividing attachment 4th axis | |

| with teilstock | |

| 3-jaw chuck diameter | 160 mm |

| Collet device | |

| Set of toolholders | |

| Handwheel electroinic |

Need Assistance? Just WhatsApp Us!

Need Assistance? Just WhatsApp Us!