1

/

of

14

KIRA KN- 40Hb

Type: KN- 40Hb

Manufacturer: KIRA

Group: Machining center

Subgroup: Horizontal machining center

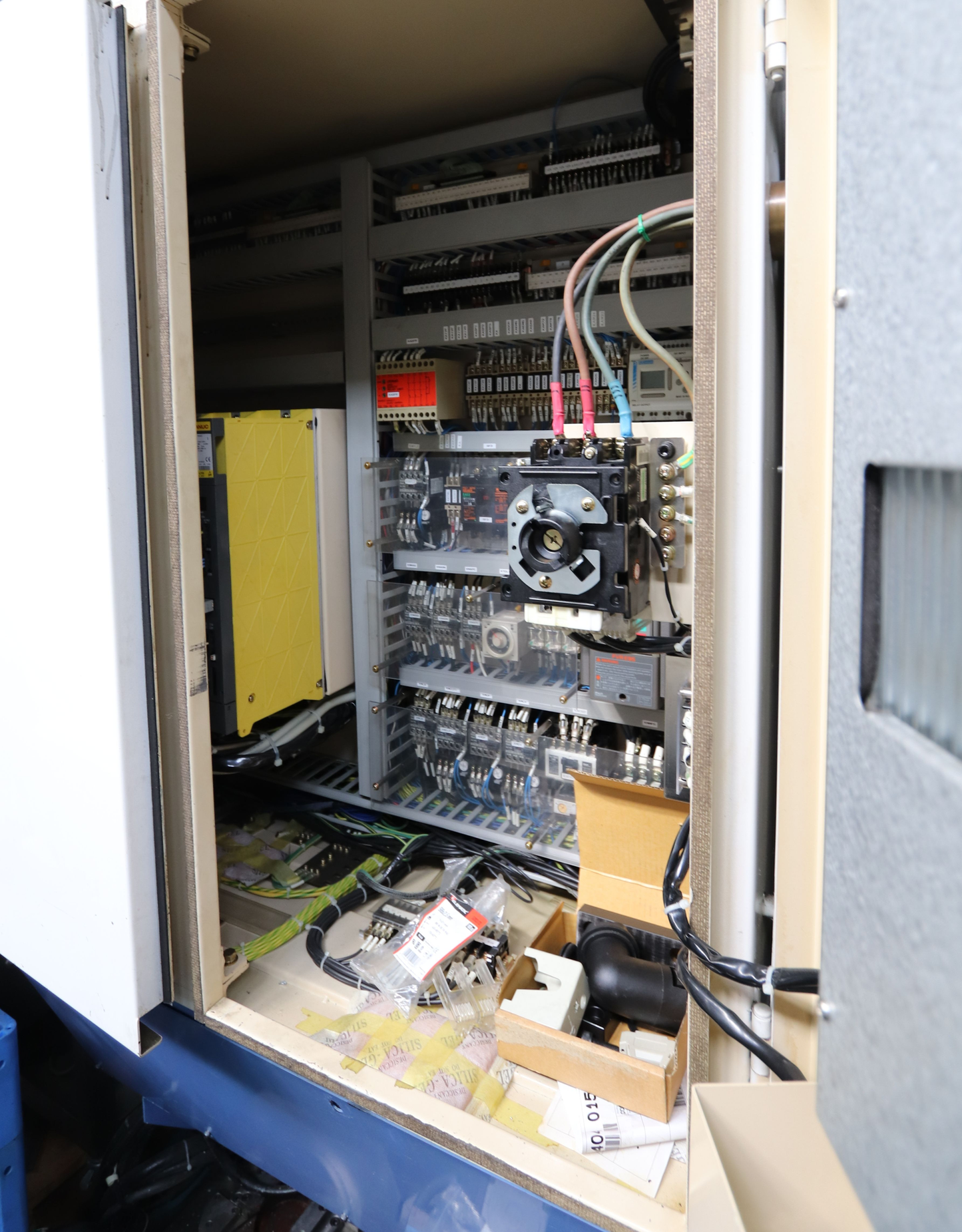

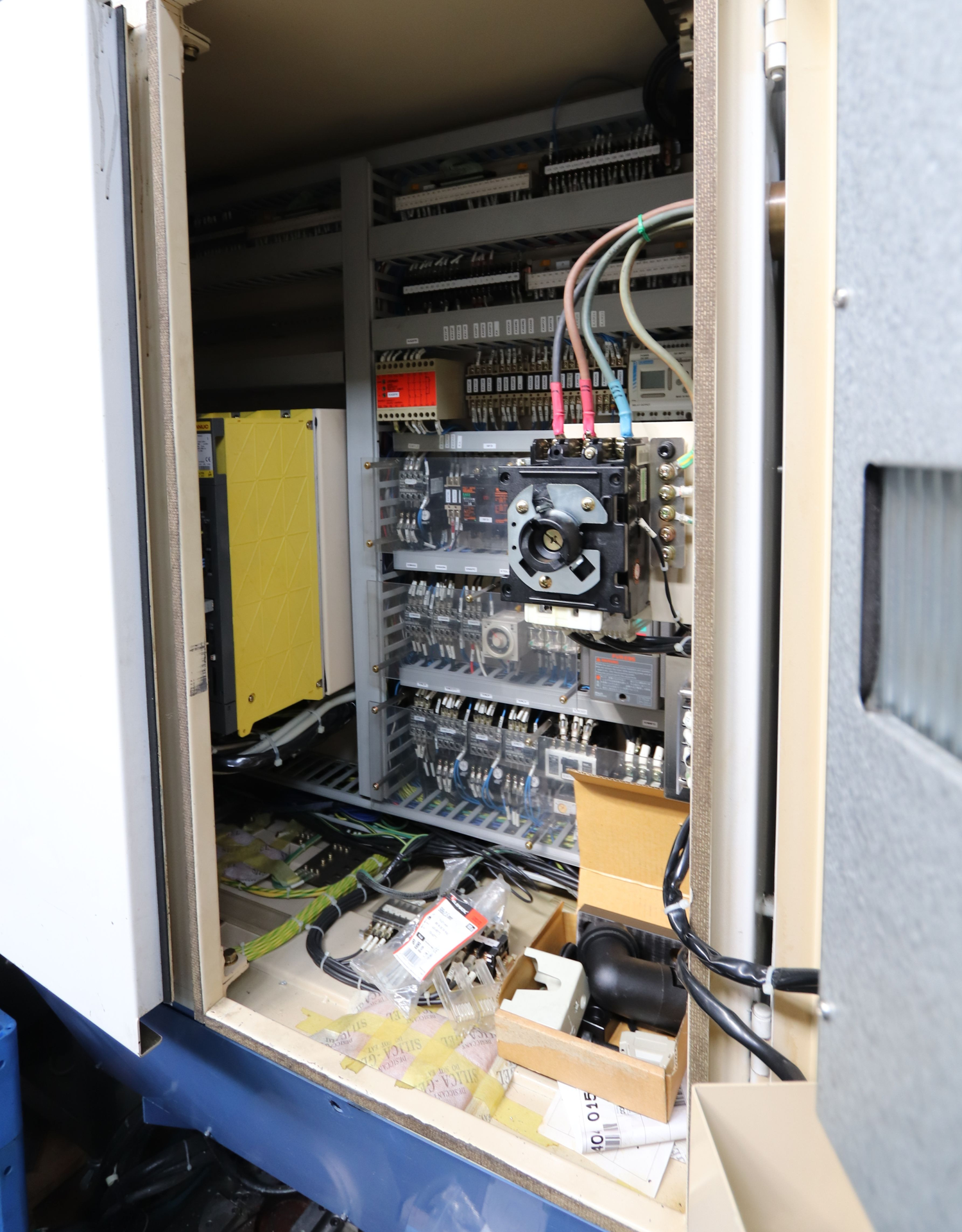

Control: FANUC 21I-MA

Stock: 013523

Special Price

Special Price

CHF 28 000

Special offer machines are sold as-is, without any warranty or inspection from us.

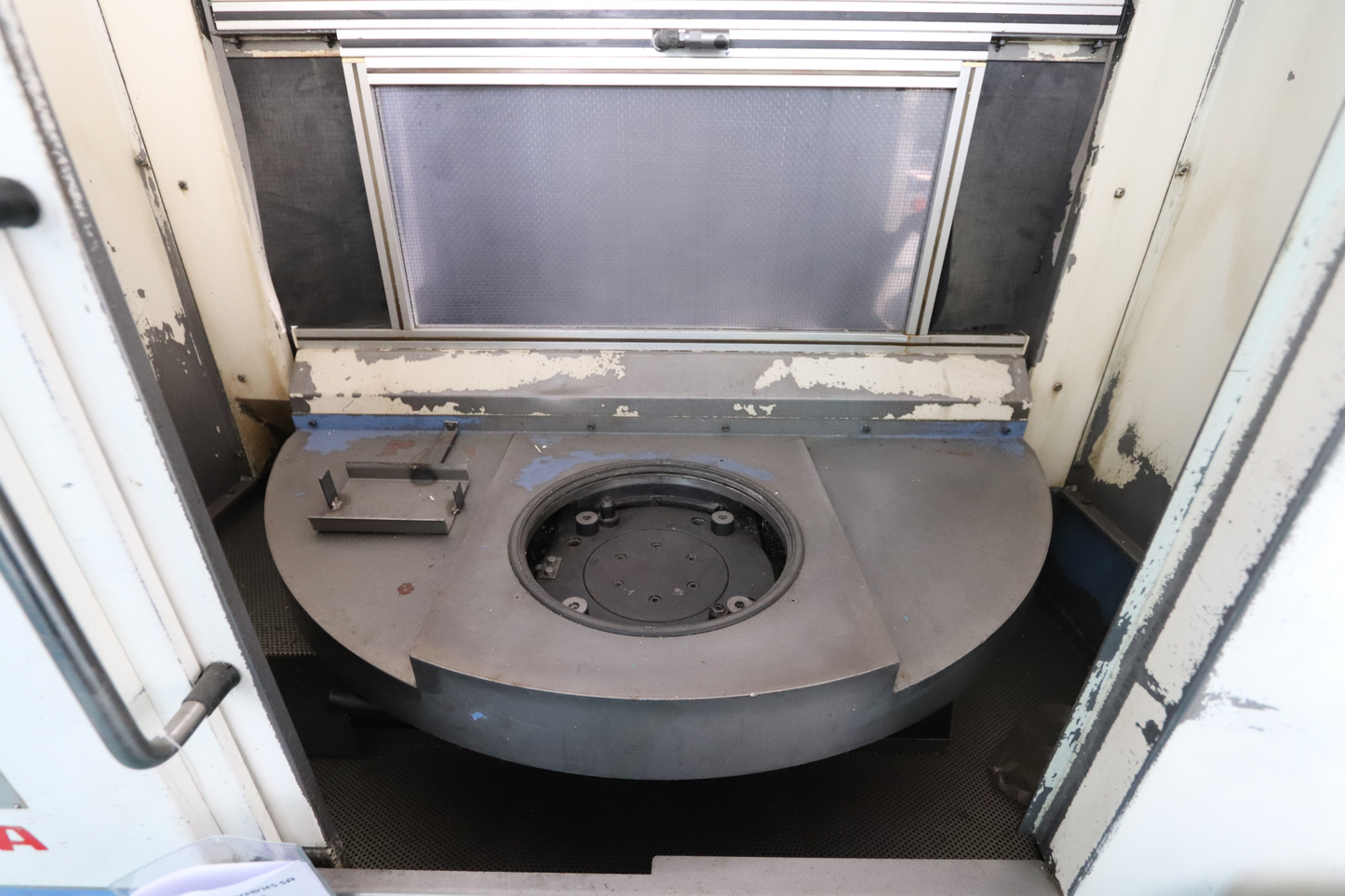

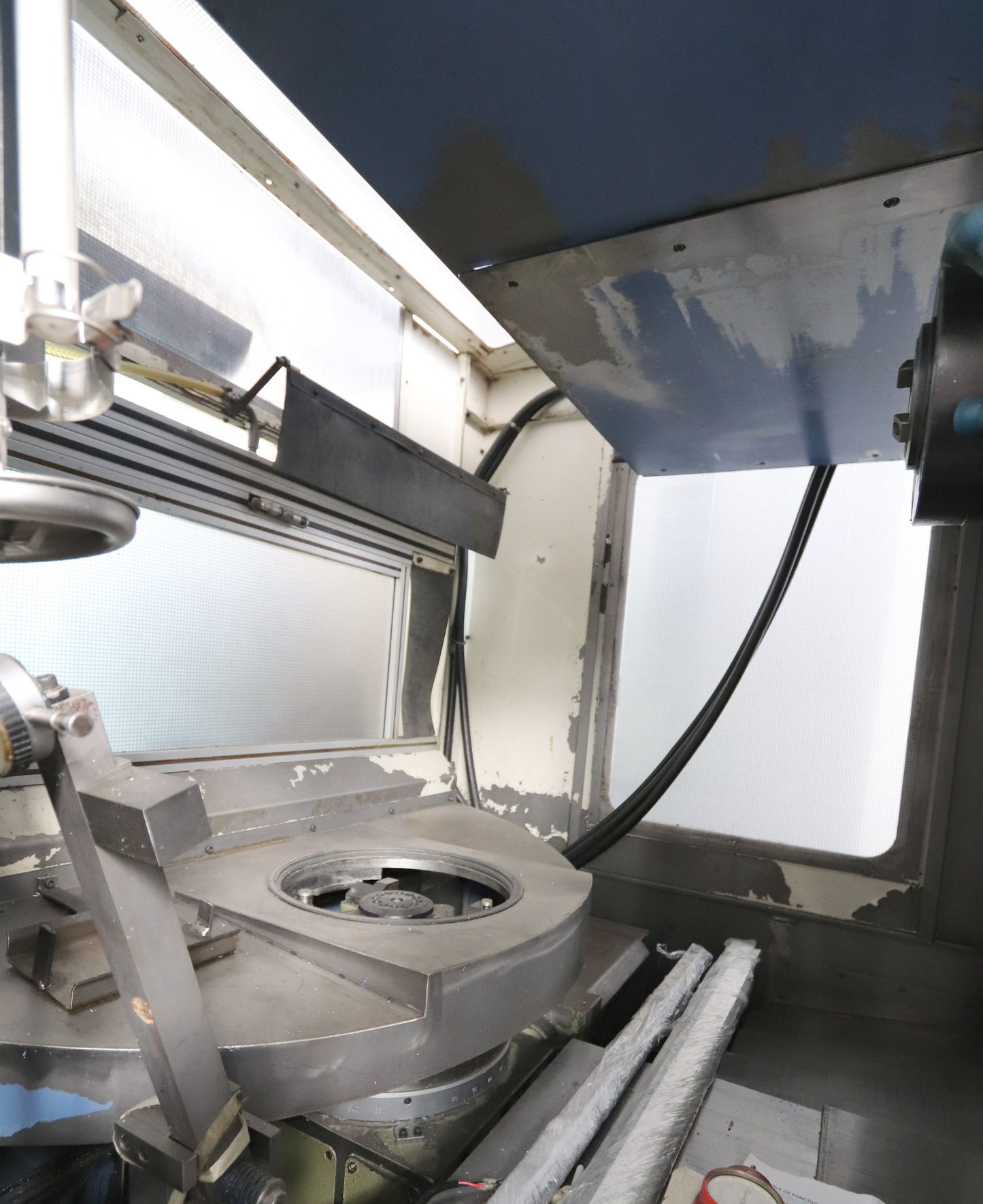

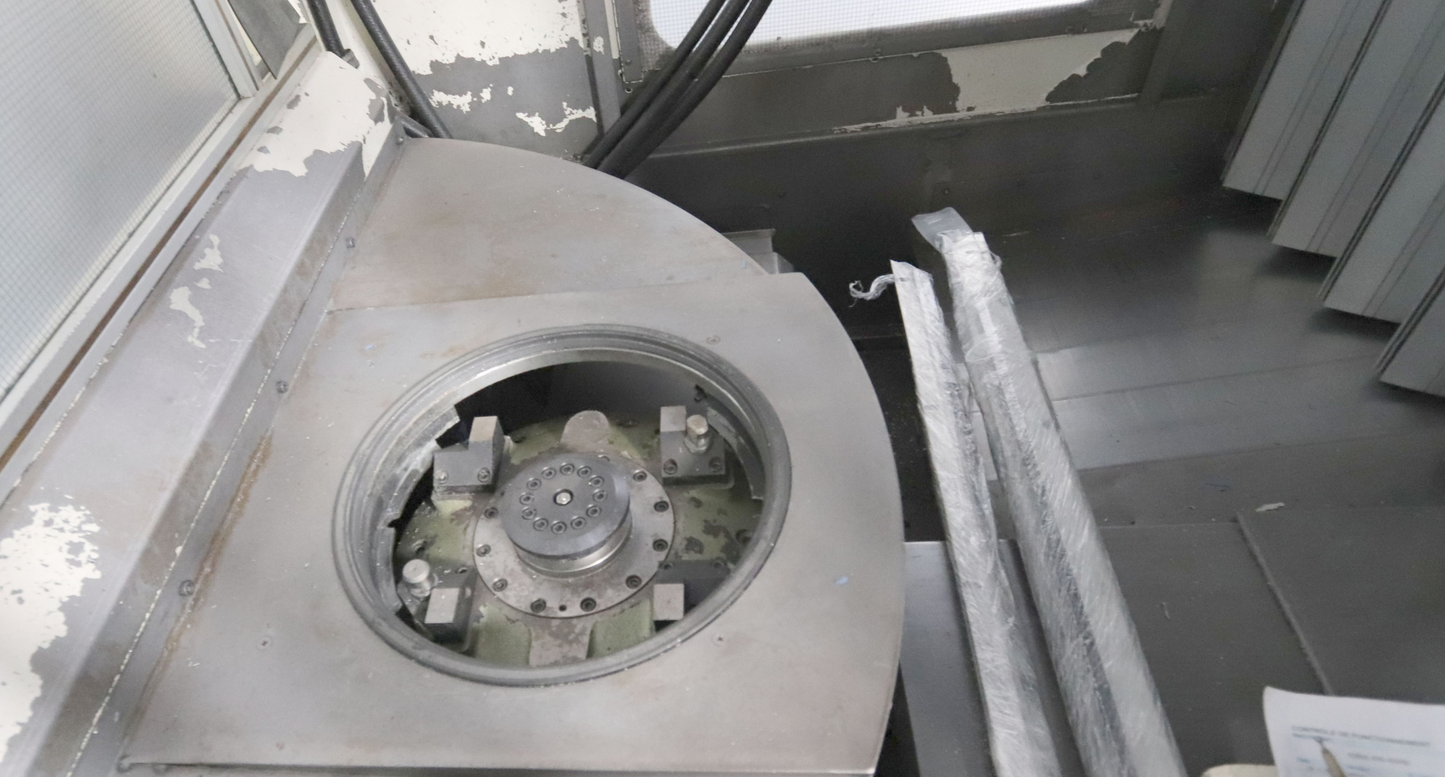

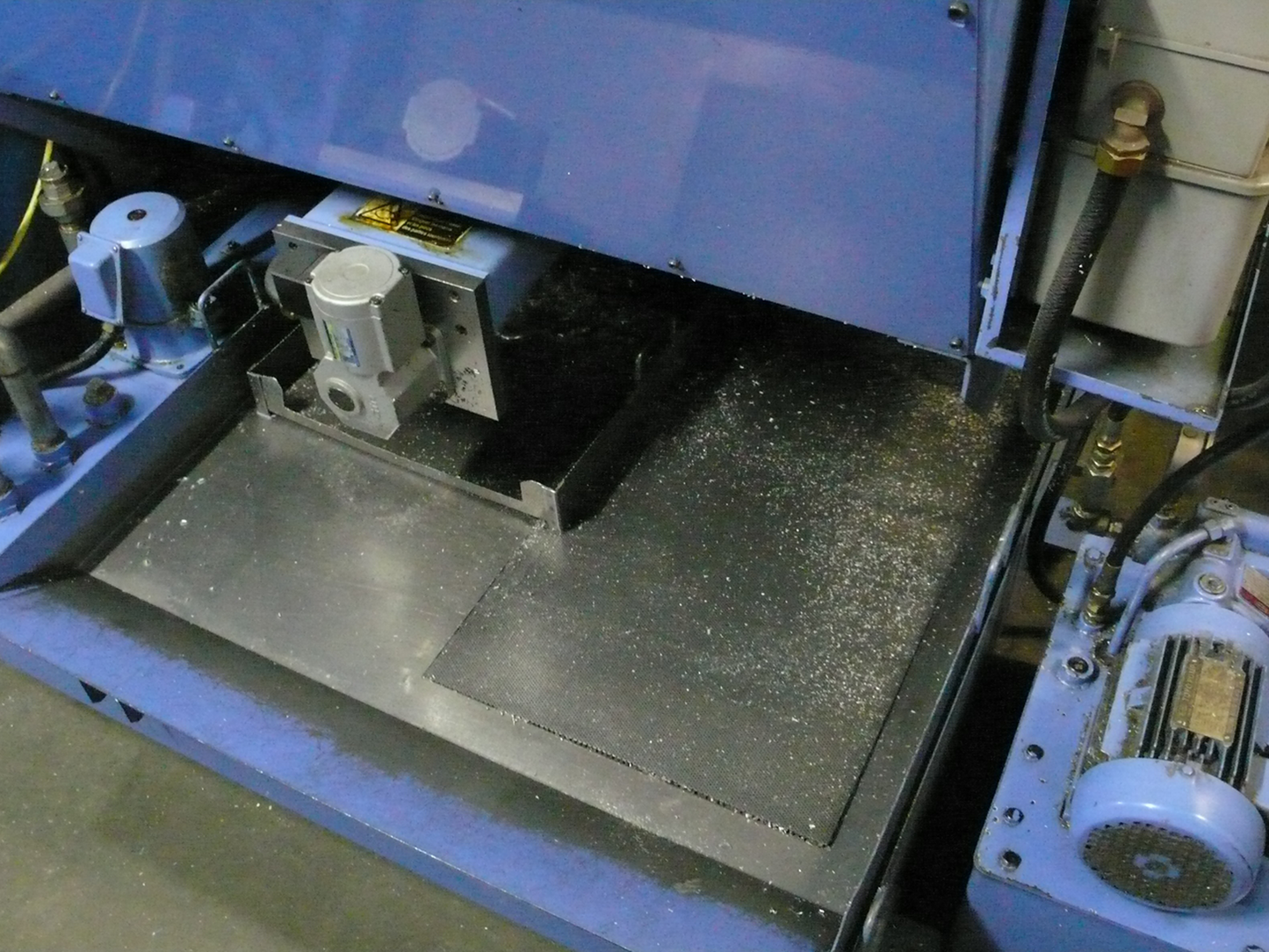

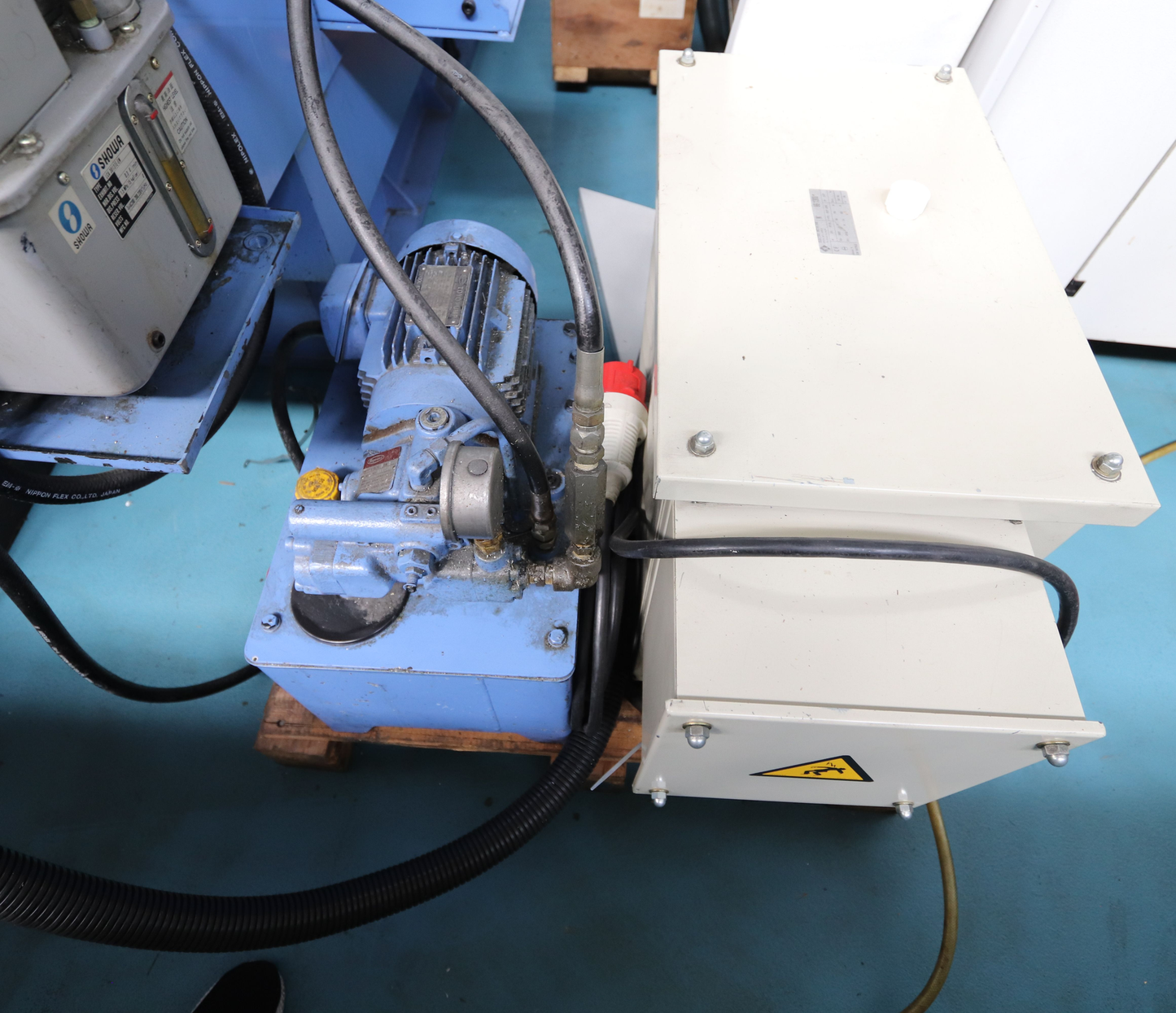

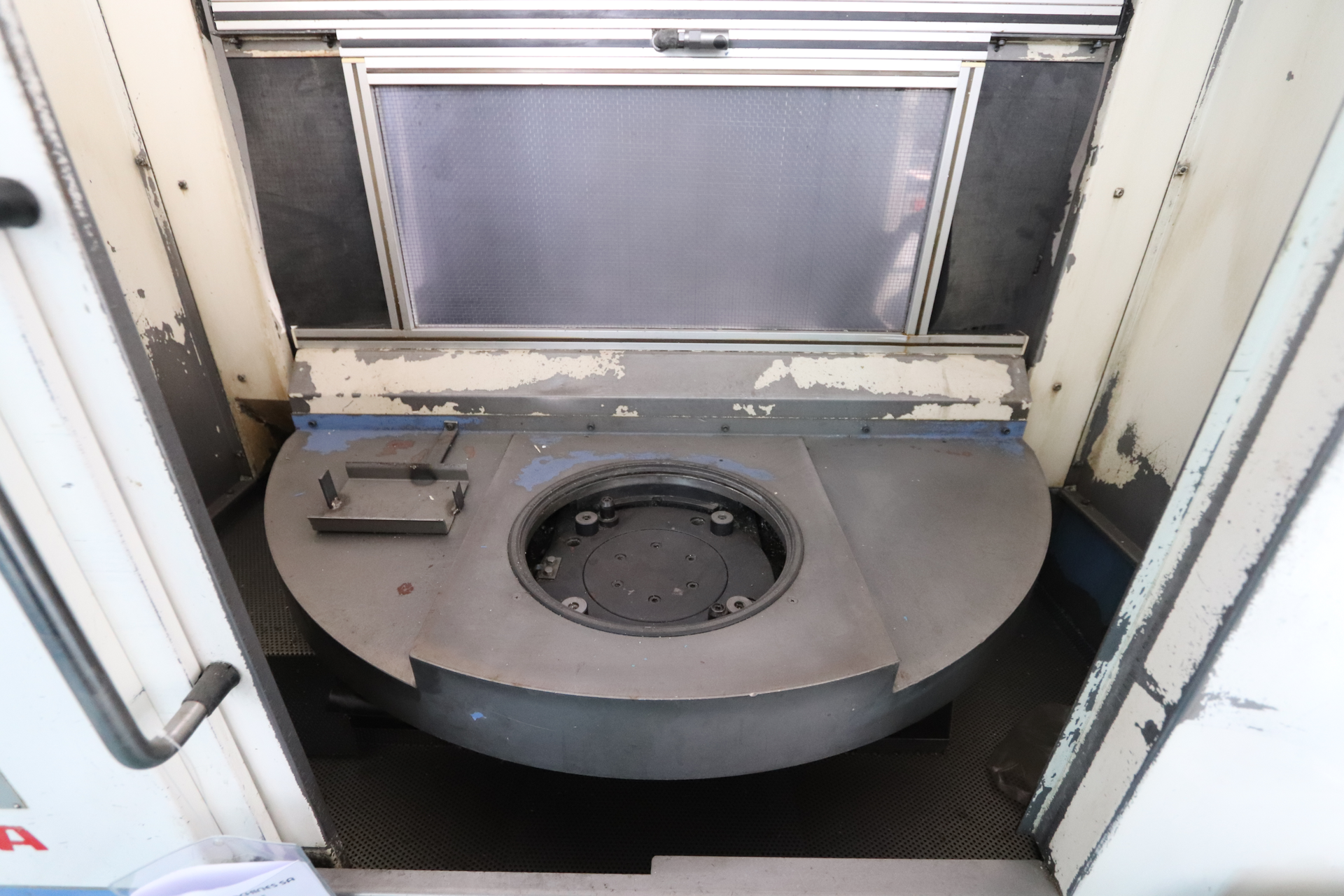

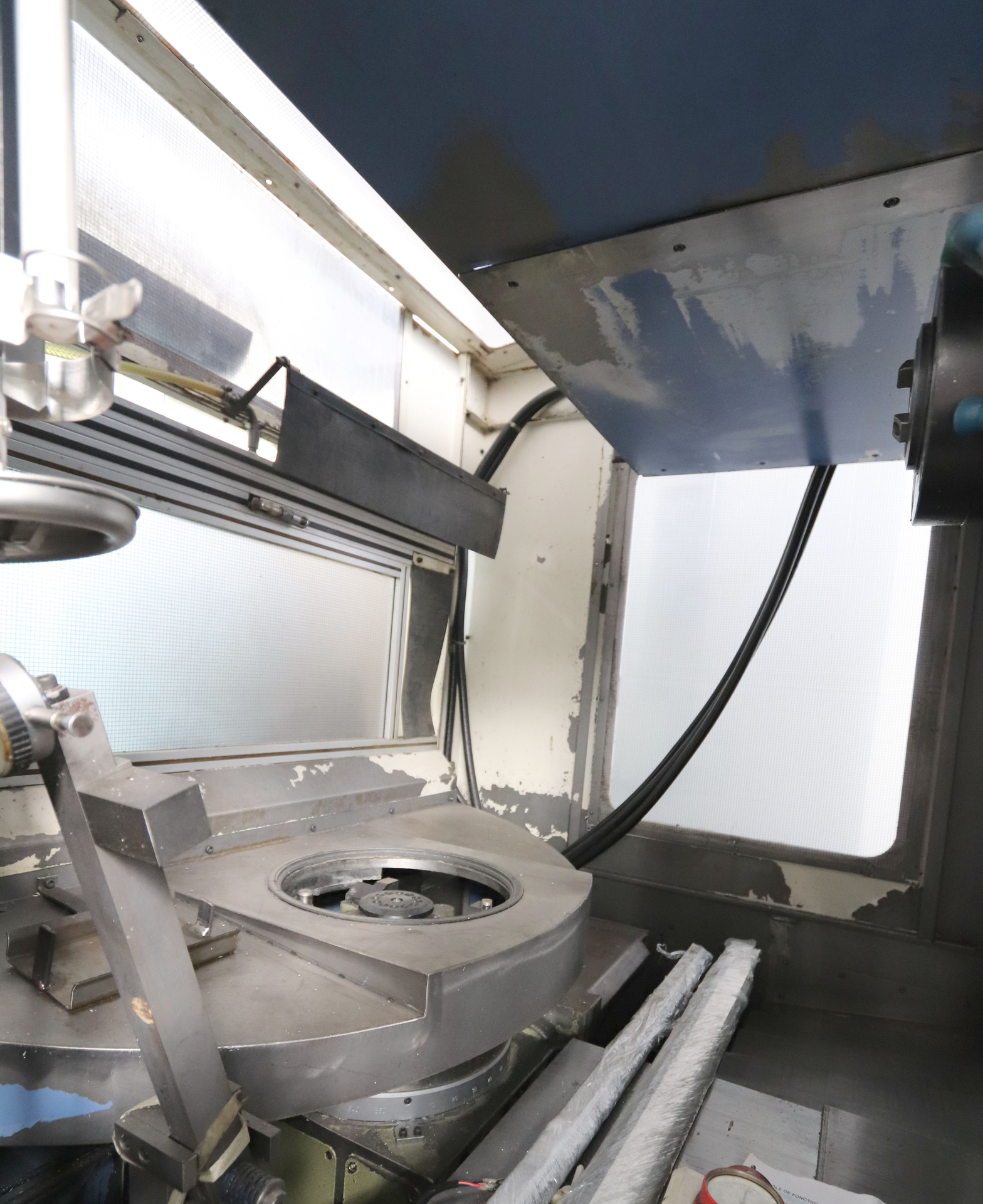

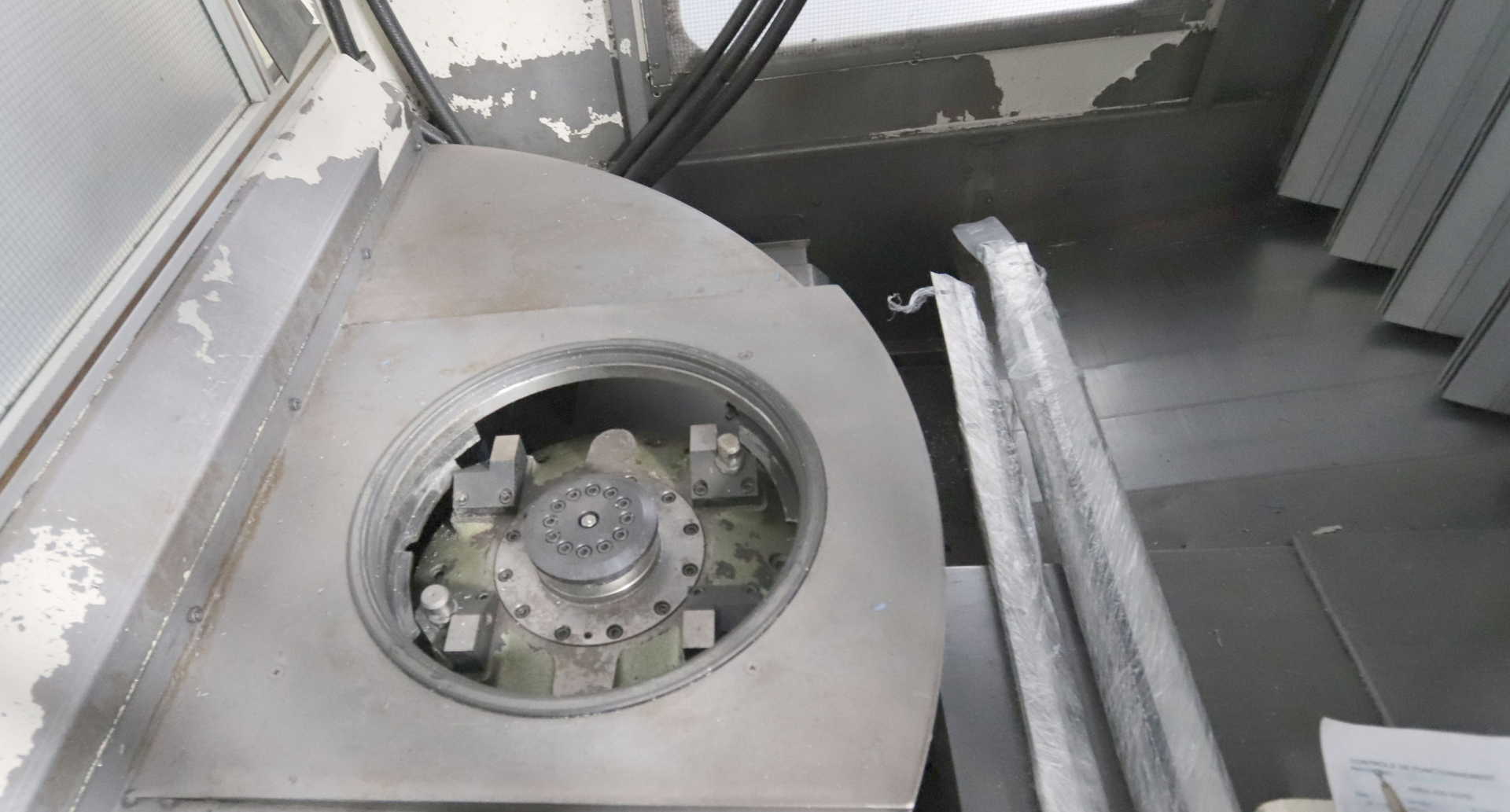

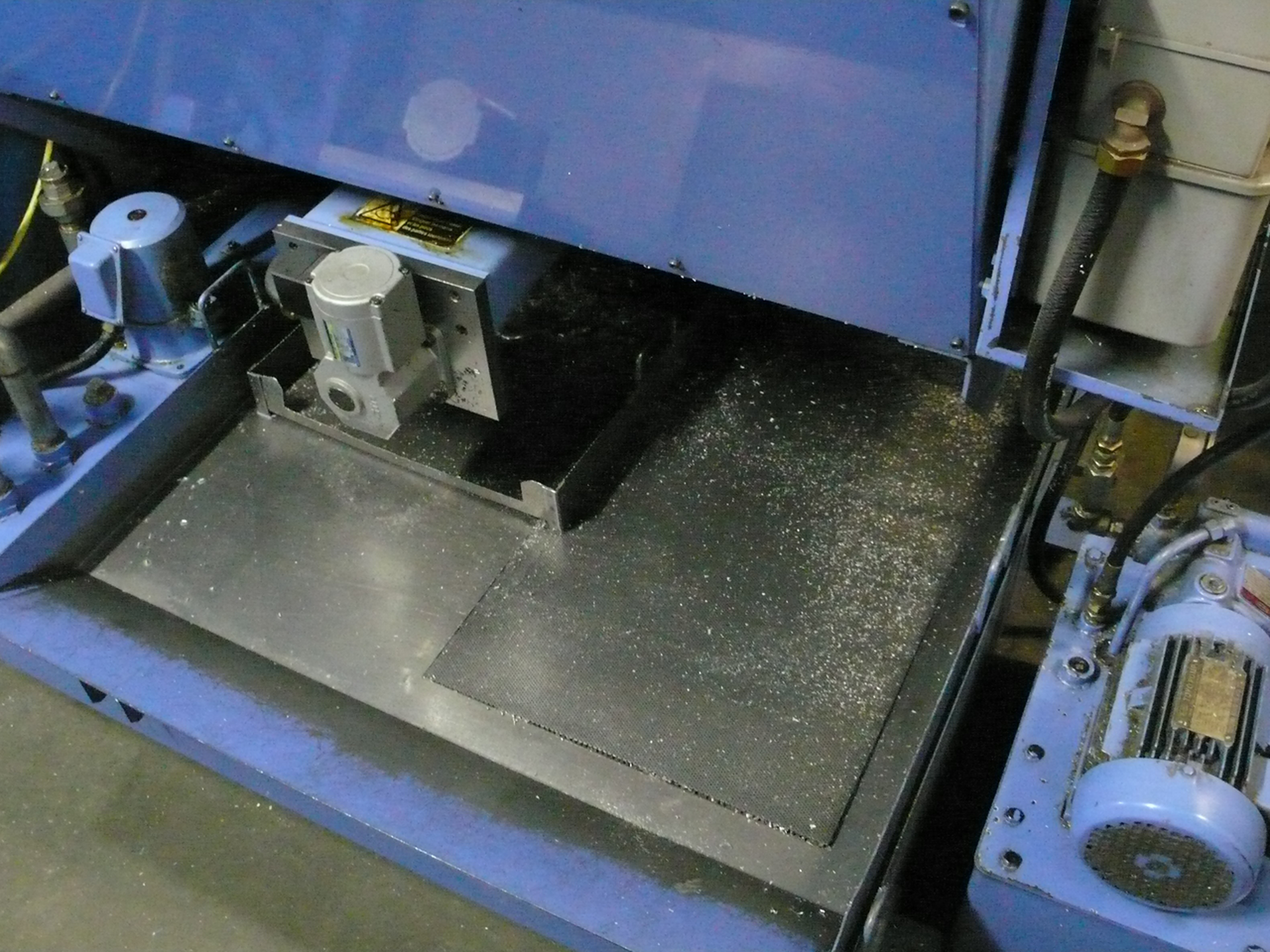

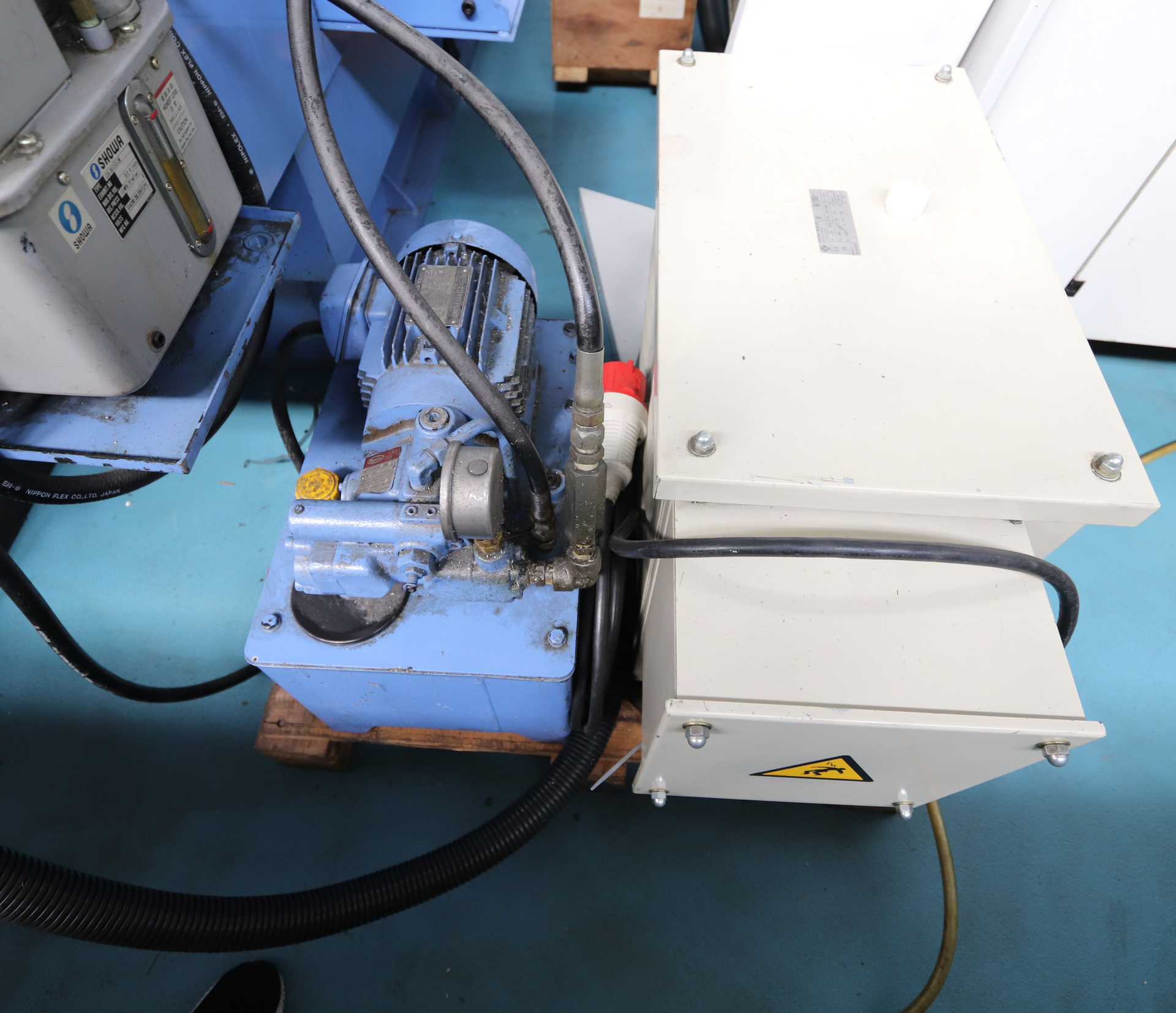

KIRA KN- 40Hb is a Horizontal machining center built for high precision, tight accuracy and reliable production. Travels X500 Y400 Z400; table B divisions 360000°; 2 pallets 400×400 mm, pallet change 8 s. 20-tool changer (Ø100 mm, L250 mm, max 5 kg), tool change 1.5/3.0 s. Spindle nose BT40, stepless 160–8000 rpm. Feed 1–10000 mm/min, rapid 48 m/min. Spindle motor 5.5/3.7 kW. Footprint 3550×1600×2600 mm, weight ~4000 kg. Accessories: double-gripper tool changer, full splash cabin, coolant system, 3D probe, chip conveyor, lamp. Delivers tight tolerances; suited to automotive, aerospace, medical, watchmaking and machine-tool sectors.

| Rotary table:diameter | mm |

| Longitudinal travel (X-axis) | 500 mm |

| Transversal travel (y-axis) | 400 mm |

| Vertical travel (z axis) | 400 mm |

| Table divisions (B) | 360000 ° |

| Pallets: | |

| numbers | 2 |

| Length | 400 mm |

| Width | 400 mm |

| Time of changing palets | 8 s |

| Tool changer: | |

| Number of tools | 20 |

| Tool diameter | 100 mm |

| Tool lenght | 250 mm |

| Max. tool-weight | 5 kg |

| Time of tool changing | 1.5 / 3.0 s |

| Spindle nose: | BT 40 |

| Horizontal spindle speeds: | |

| stepless | |

| from | 160 t/min |

| up to | 8000 t/min |

| Feed range | 1 - 10000 mm/min |

| Rapid traverse: | 48 m/min |

| Spindle motor | 5.5 / 3.7 kW |

| Machine's weight about | 4000 kg |

| Overall dimensions machine: | |

| Length | 3550 mm |

| Width | 1600 mm |

| Height | 2600 mm |

| Various accessories: | |

| Tool changer: | |

| with double gripper | |

| Number of tools | 20 |

| Full splash cabin | |

| Coolant system | |

| 3D measuring feeler gauge | |

| Chip conveyor | |

| Lamp |

Need Assistance? Just WhatsApp Us!

Need Assistance? Just WhatsApp Us!