1

/

of

14

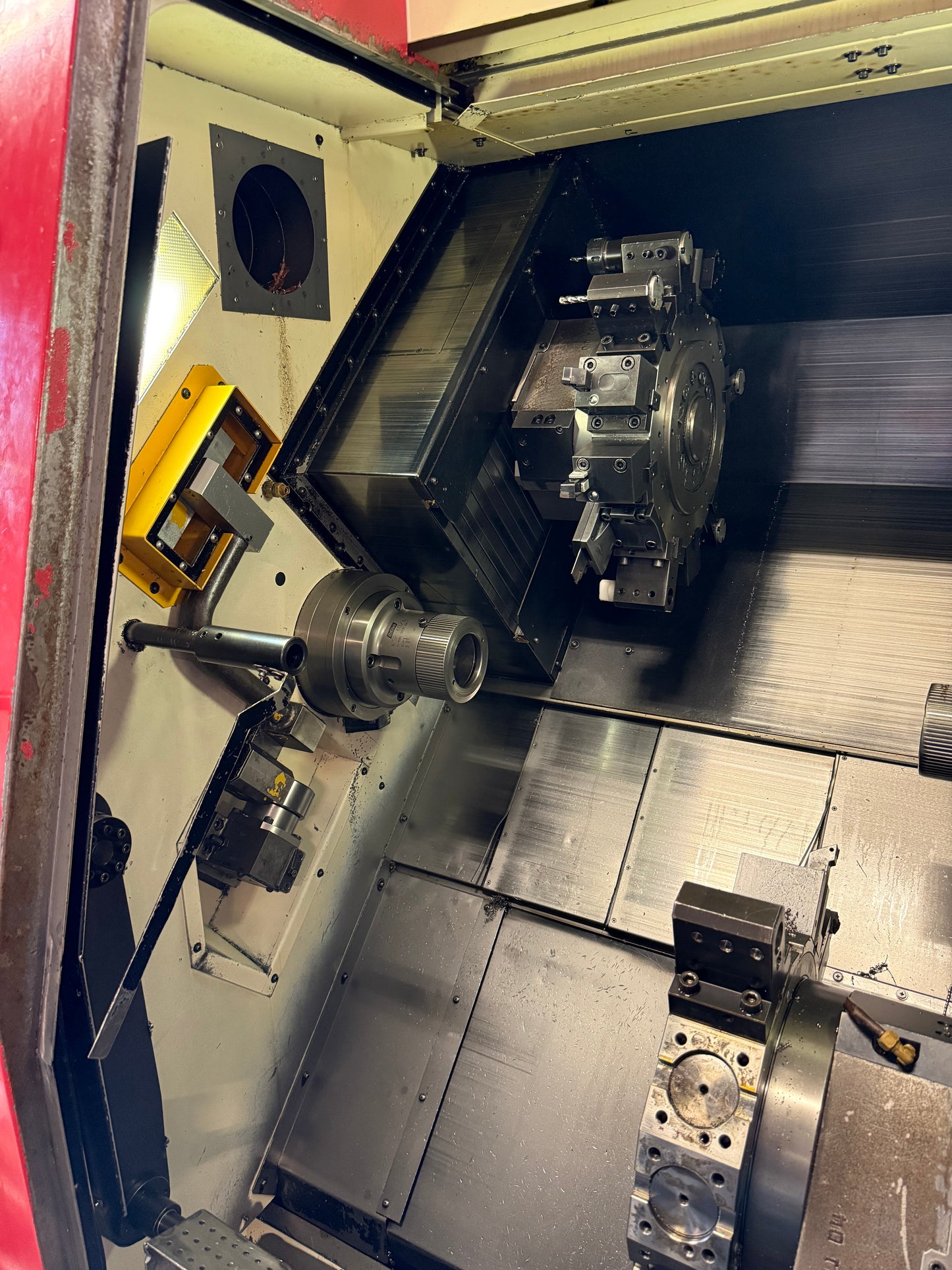

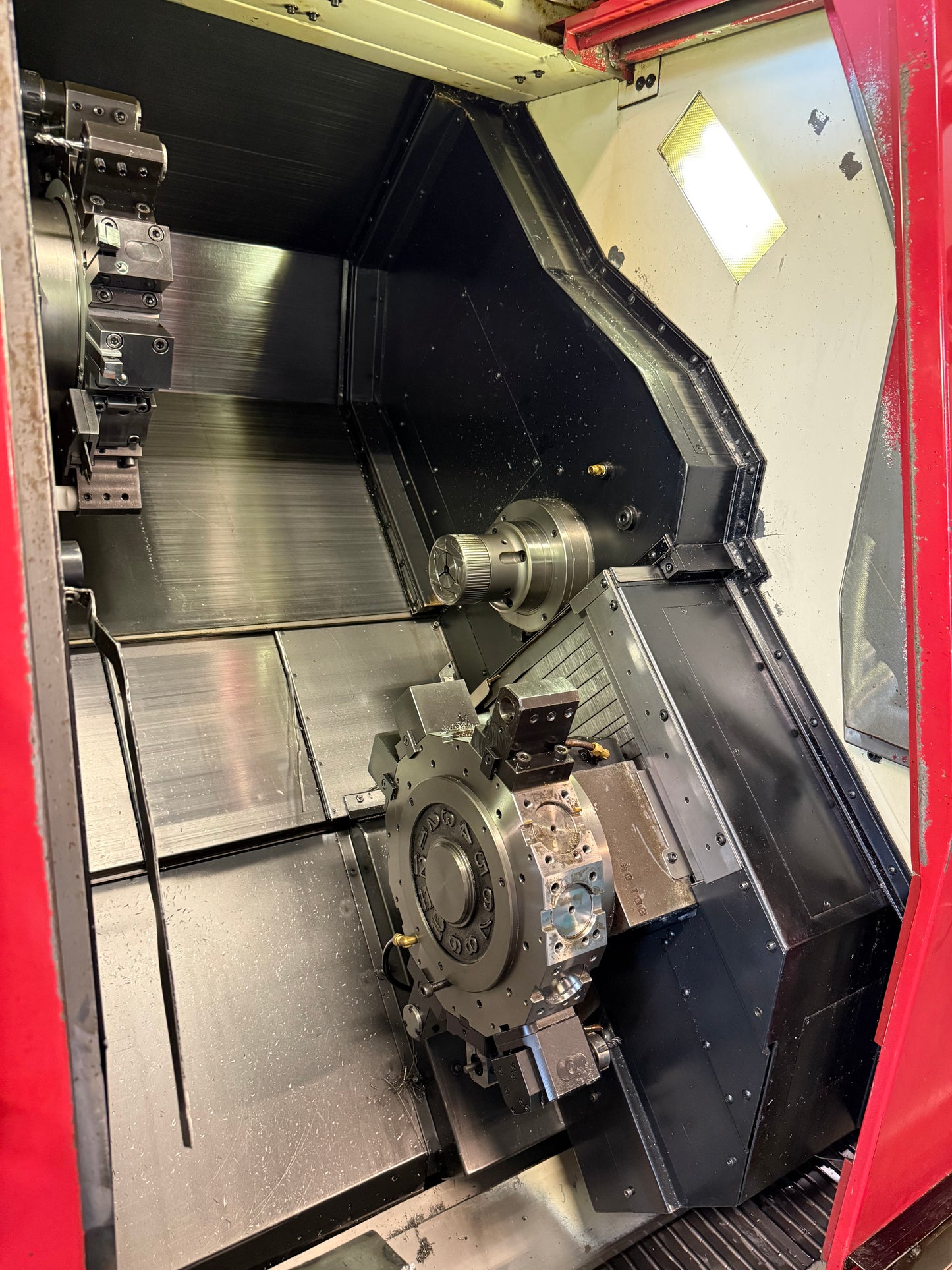

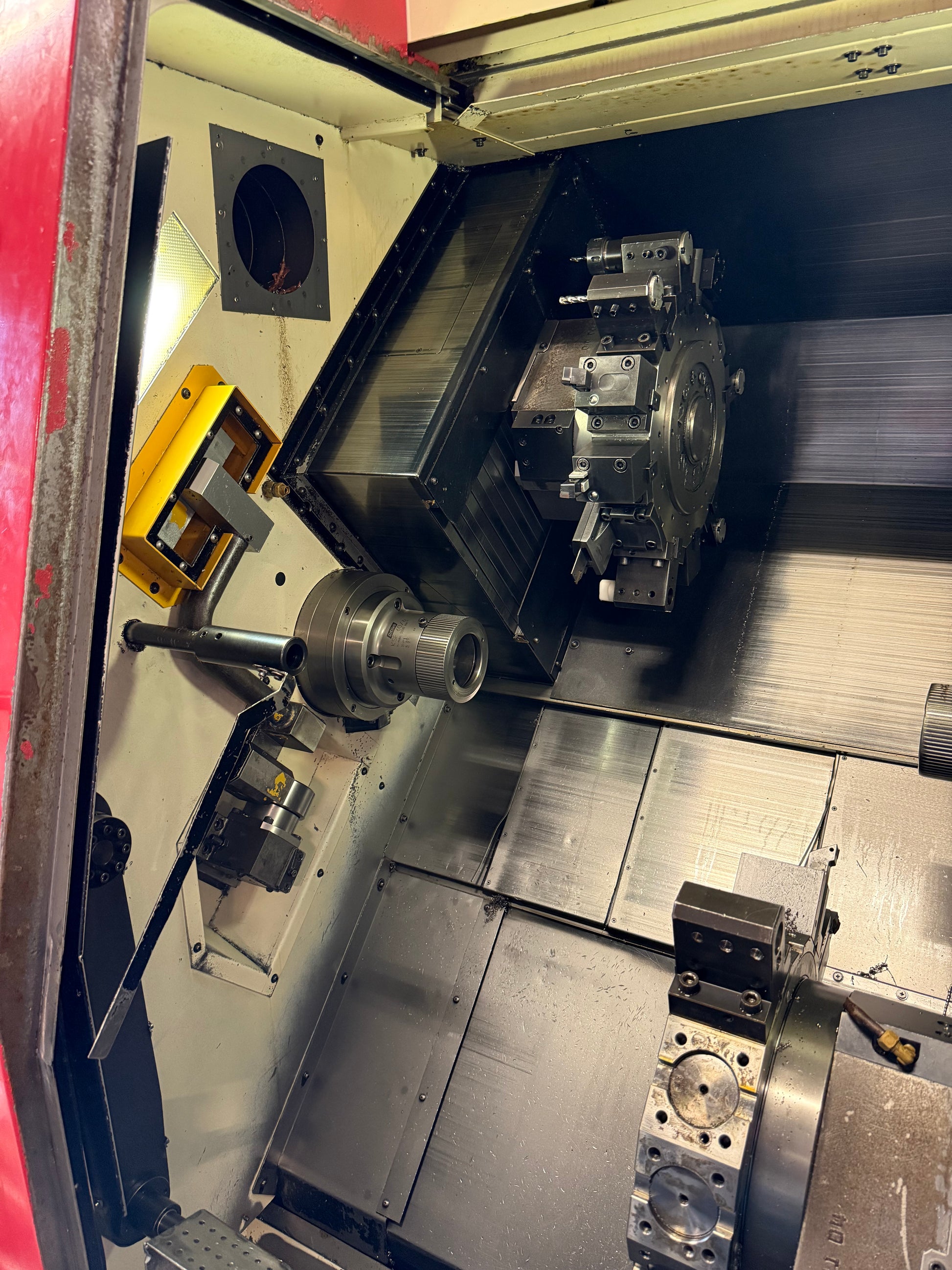

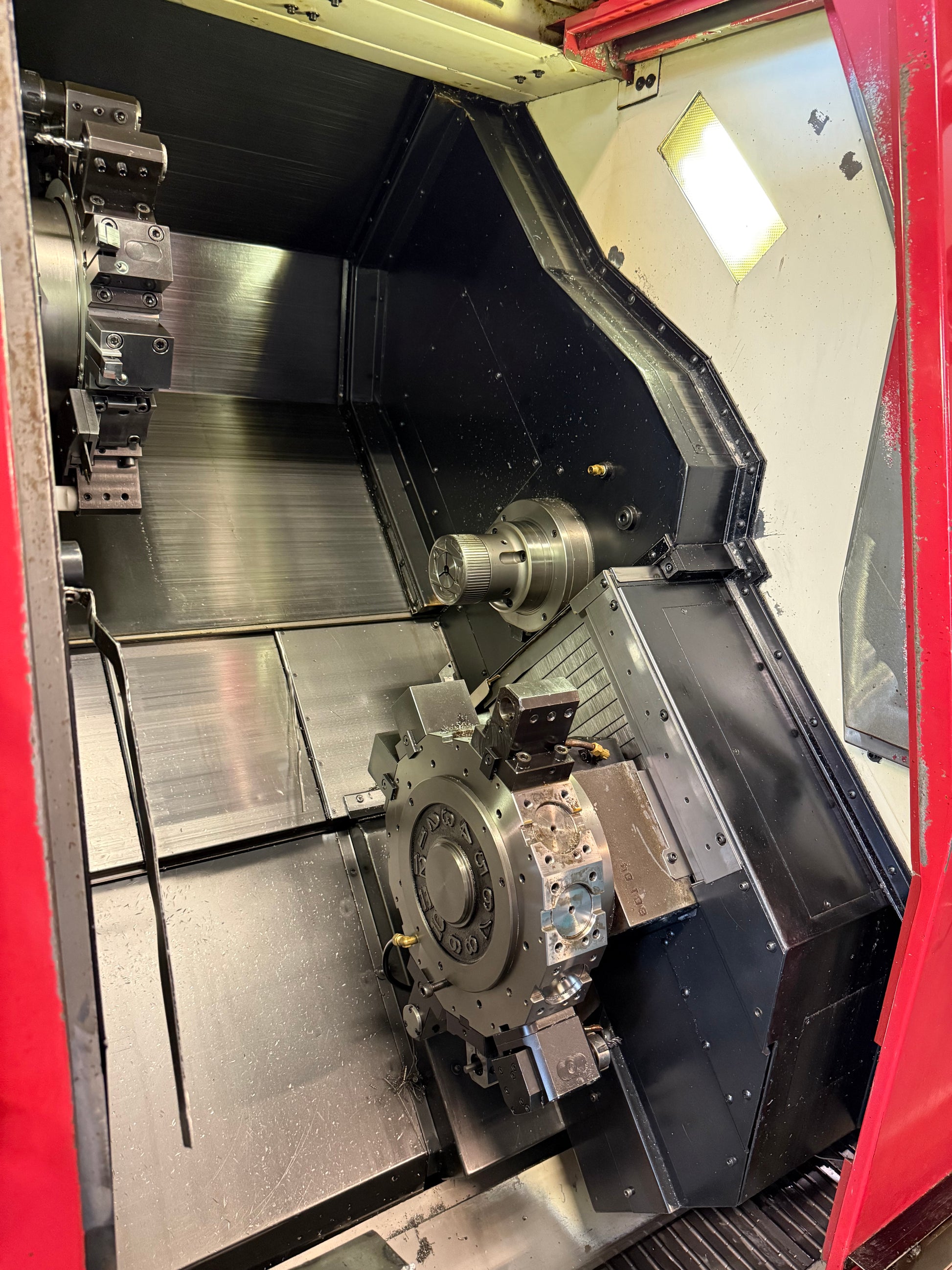

NAKAMURA-TOME WT 250

Type: WT 250

Manufacturer: NAKAMURA-TOME

Group: CNC turning lathe

Subgroup: CNC turning lathe with two work spindles

Control: FANUC 18i-T

Stock: 023300

NAKAMURA-TOME WT 250 is a CNC turning lathe with two work spindles, engineered for high precision, superior accuracy and reliability. Capacities: max turning length 555 mm, max diameter 250 mm, bar passage 65 mm; travels Z 600 mm, X 195 mm, Y ±41 mm; 2 turrets with 12 positions each. Specs: 7 axes; spindle speeds 20–4500 rpm (noted 3600 rpm); spindle power 18.5/15 kW; back spindle max 5000 rpm, 11/7.5 kW; C‑axis 0.001°; 3×400 V 50 Hz; weight ≈6500 kg; footprint 3500×3000×2200 mm. Accessories: Hydro‑Sameca barfeeder, coolant, chip conveyor, part conveyor, 3‑jaw chuck, jaw sets, collets, toolholders. Enables tight tolerances; suited to automotive, aerospace, medical, watchmaking and toolmaking.

| Number of axis total | 7 |

| Number of spindles | 2 |

| Number of revolvers | 2 |

| Maximum turning length | 555 mm |

| Max. turning diameter | 250 mm |

| Bar passage | 65 mm |

| Turret carriage: | 2 |

| Carriage 1: | |

| Travels: | |

| Longitudinal travel (Z-axis) | 600 mm |

| Transversal strocke (X axis) | 195 mm |

| Transversal travel (y-axis) | +/- 41 mm |

| Carriage 2: | |

| Longitudinal travel (Z-axis) | 600 mm |

| Longitudinal travel (X-axis) | 195 mm |

| Transversal travel (y-axis) | +/- 41 mm |

| Number of positions turret 1 | 12 |

| Number of positions turret 2 | 12 |

| Driven tools turret 1 | 12 |

| Spindle speeds | 3600 t/min |

| Taper in spindle: | |

| Camlock | A2-6" |

| C axis (spindle,resolution) | 0.001 ° |

| Spindle speeds: | |

| from | 20 t/min |

| up to | 4500 t/min |

| Spindle power | 18.5 / 15 kW |

| Back spindle: | |

| Spindle nose | A2-5 |

| max. speed | 5000 t/min |

| C axis (spindle,resolution) | 0.001 ° |

| Power of back spindle | 11 / 7.5 kW |

| Voltage 50 Hz 3x | 400 Volt |

| Machine's weight about | 6500 kg |

| Overall dimensions machine: | |

| Length | 3500 mm |

| Width | 3000 mm |

| Height | 2200 mm |

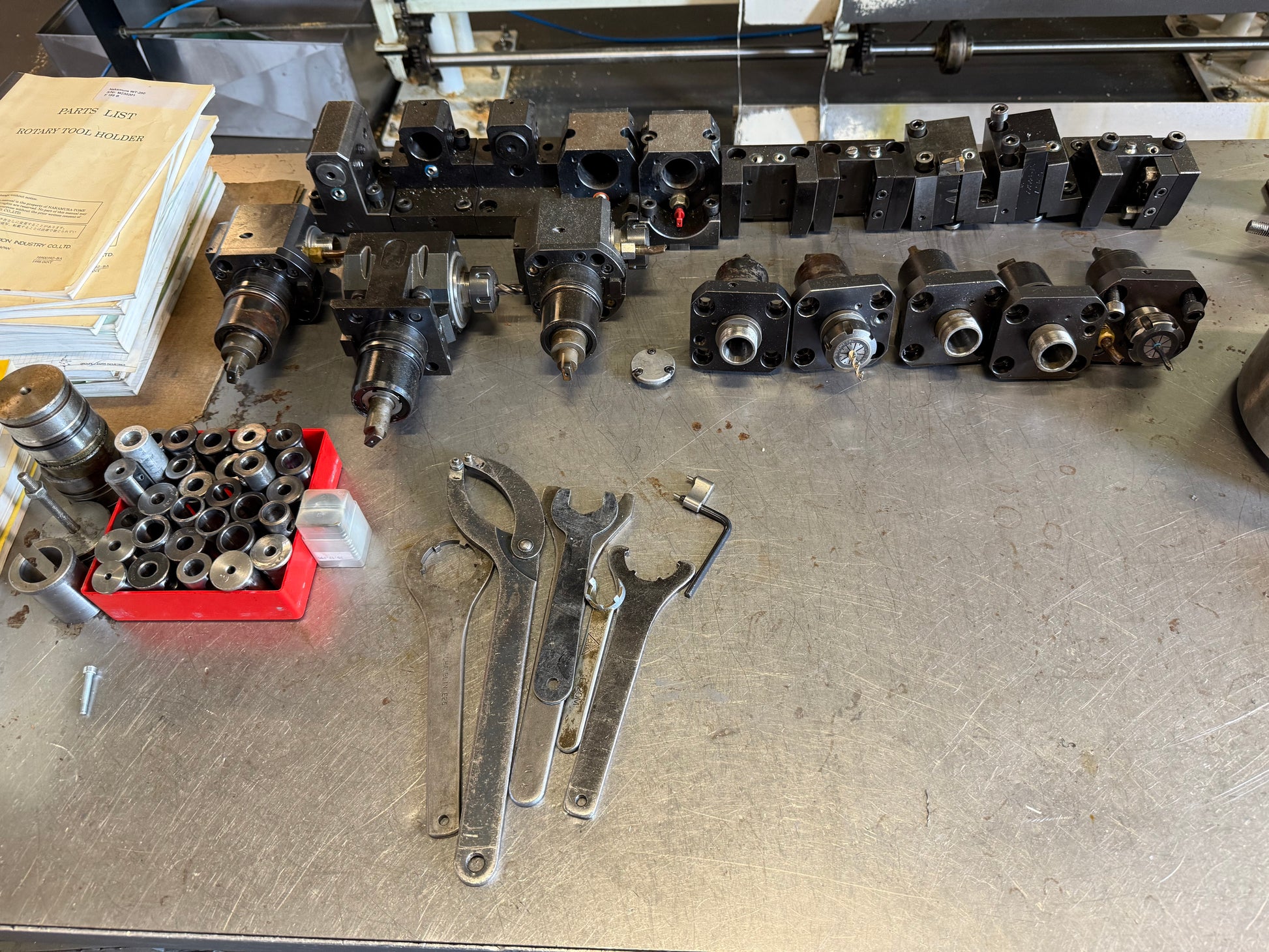

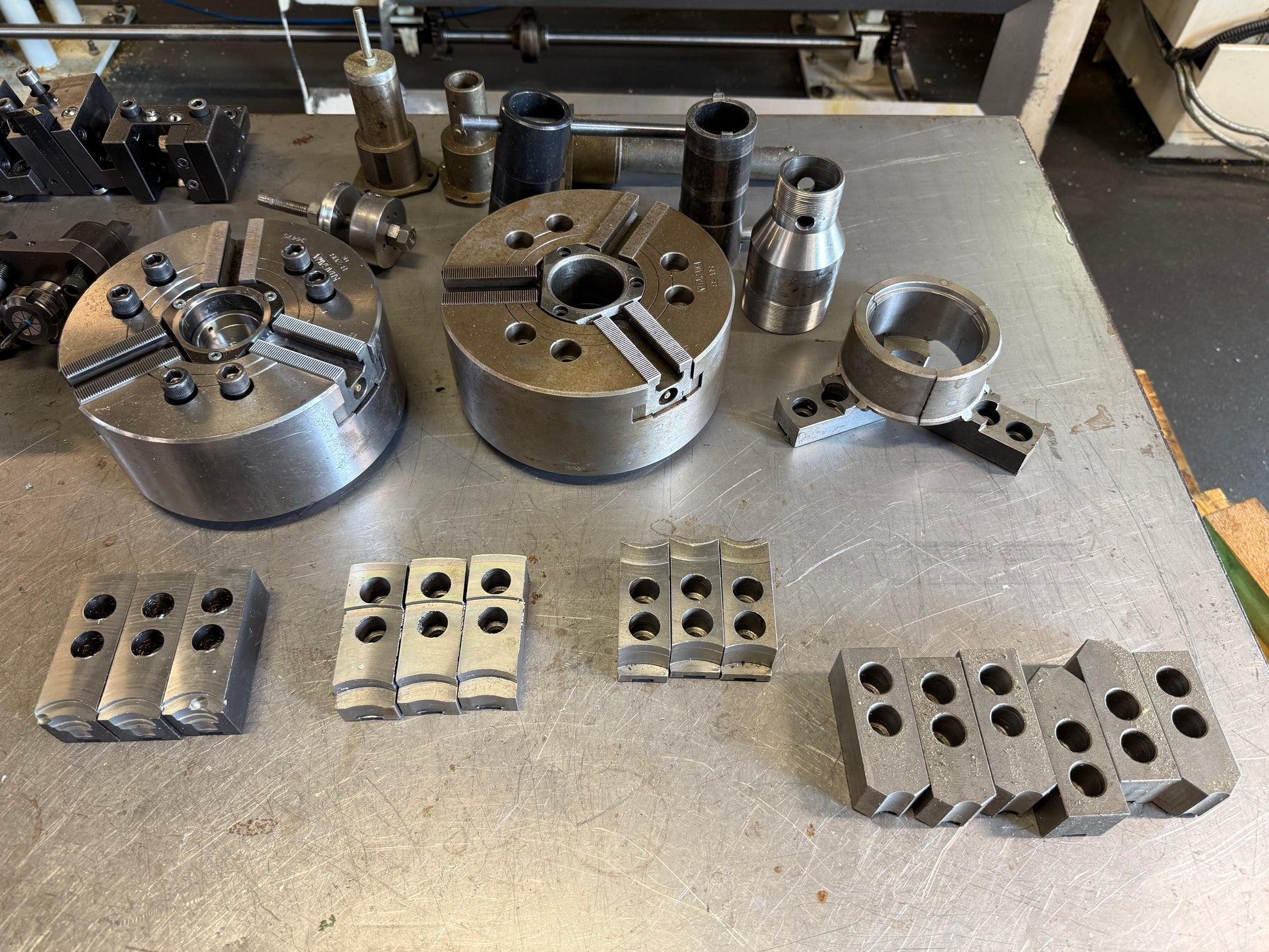

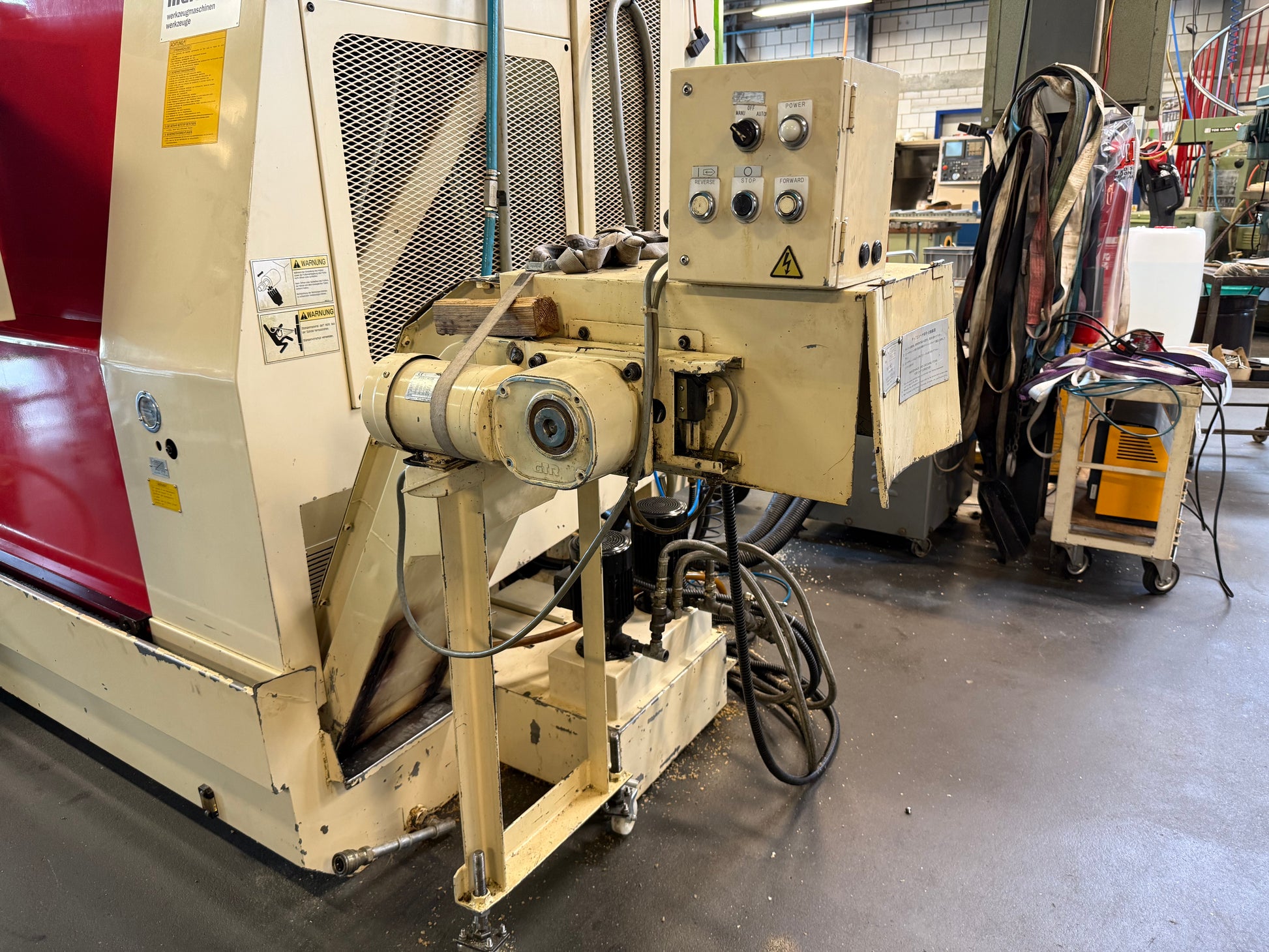

| Various accessories: | |

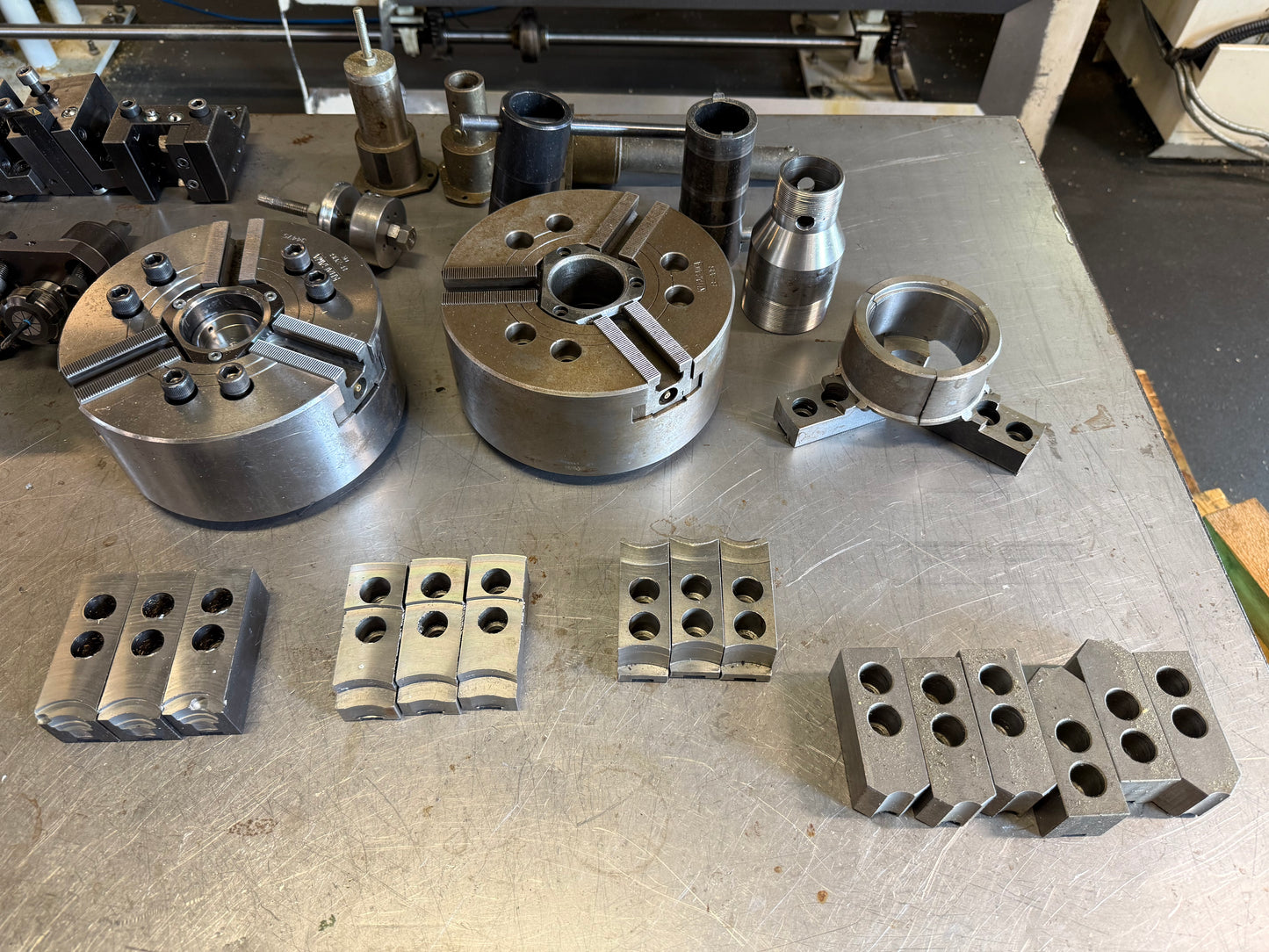

| 3-jaw chuck | |

| Set of soft jaws | |

| Set of hard jaws | |

| Set of collets | |

| Coolant system | |

| Bar feeder | Hydro-Sameca |

| Workpiece conveyor | |

| Chip conveyor | |

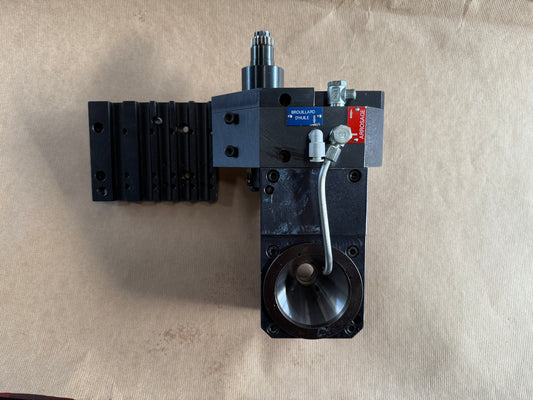

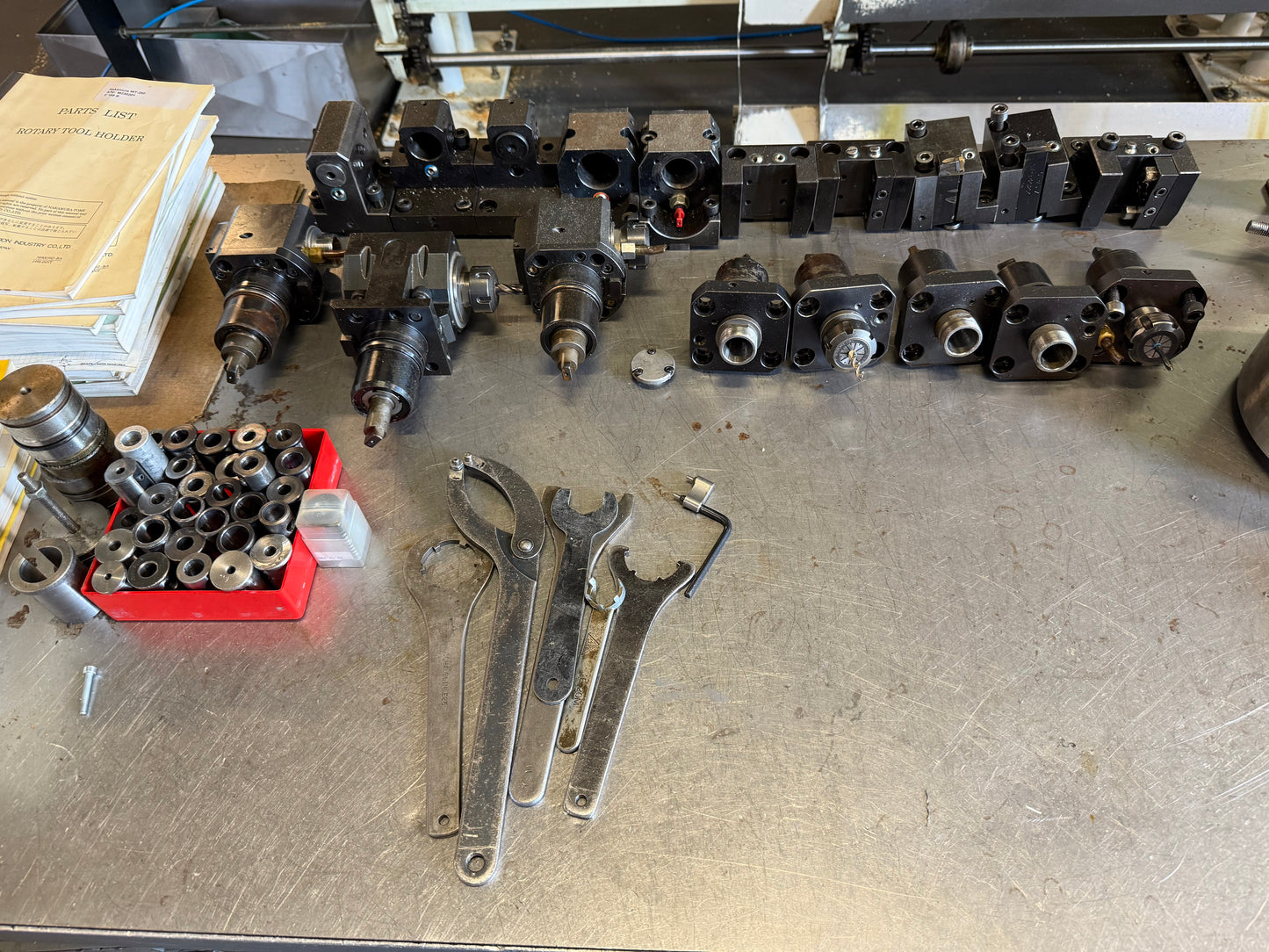

| Set of toolholders |

Need Assistance? Just WhatsApp Us!

Need Assistance? Just WhatsApp Us!